D2 tool steel and 440C stainless steel are often regarded as highly esteemed yet controversial...

The four most common heat treatments are: annealing, normalizing, hardening, and tempering...

THE FOLLOWING STORIES OF OUR CLIENTS ARE ALL REAL. TO PROTECT THE PRIVACY OF OUR CLIENTS, WE HAVE...

When choosing the right tool steel for your project, you may come across D2 tool steel and D3 tool...

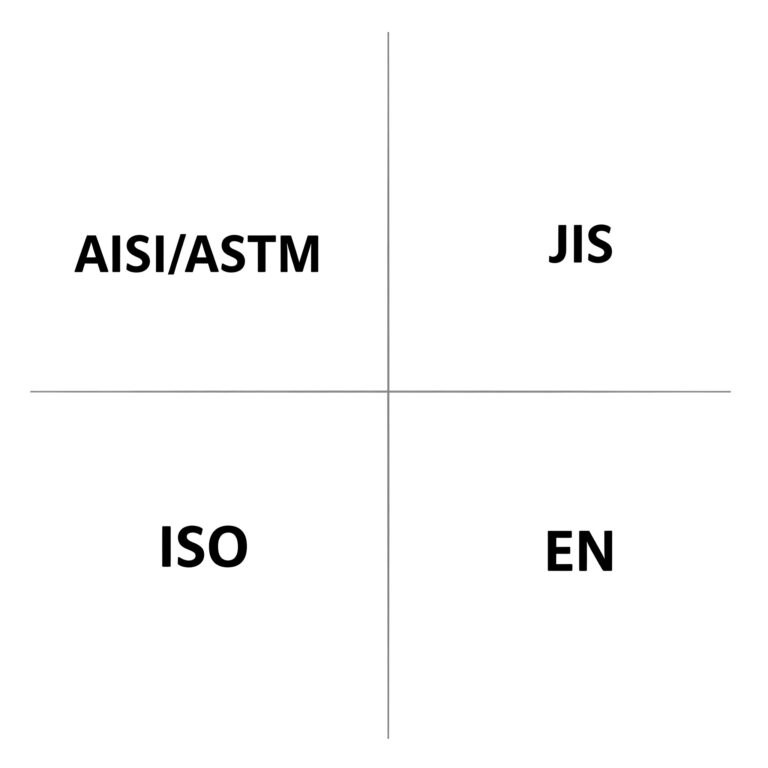

Tool steels are classified in different ways based on country standards. These include the United...

In the tool steel industry, ESR means Electroslag Remelting. To improve quality, some steel grades...

H11 vs H13 steel: H11 tool steel and H13 tool steel are both hot-work tool steels...

Our company, Aobo Steel, mainly supplies forged tool steel. This article will discuss the problems...

Within the core category of cold work tool steels, AISI A2 and D2 are widely used in industrial...