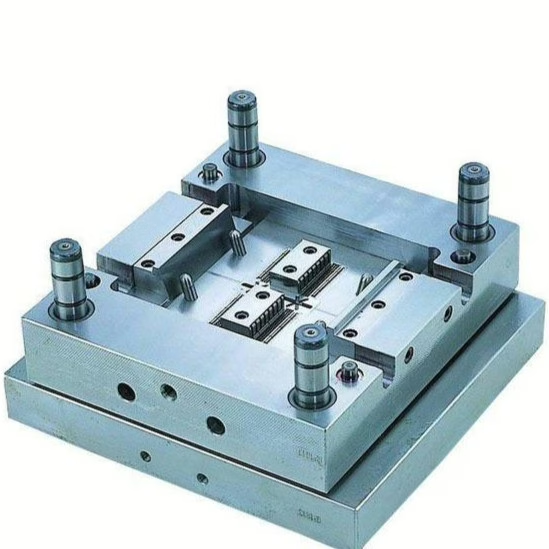

Acero P20 Es un material ampliamente reconocido y utilizado para moldes de plástico debido a la combinación de sus propiedades inherentes y las ventajas de fabricación que ofrece. Es el grupo de aceros más importante y común para moldes de plástico. Entonces, ¿cuáles son las ventajas de usar acero P20 en aplicaciones de moldes? Analicémoslas.

Estas son las principales ventajas:

- Condición pre-endurecida (lista para servicio). El acero P20 normalmente se suministra en estado preendurecido. Dureza del acero P20 Tiene una dureza Rockwell C de aproximadamente 32 HRC. Esta es la principal ventaja del P20. Tras mecanizar la cavidad del molde, este suele poder ponerse en servicio directamente sin necesidad de un tratamiento térmico posterior a alta temperatura. Esto evita los problemas de deformación y los cambios dimensionales causados por el tratamiento térmico. Para más información sobre este tema, consulte ¿El P20 es un acero endurecido?

- Excelente maquinabilidadEl acero P20 presenta una excelente maquinabilidad. Dado que el costo del mecanizado de los moldes representa aproximadamente 80% del costo total del molde, una buena maquinabilidad ayuda a reducir los costos y el tiempo totales de producción.

- Pulibilidad superior. La solidez, la uniformidad química y estructural y el bajo contenido de inclusiones del acero P20 son las razones de su capacidad de pulido superior, lo cual es esencial para producir piezas de plástico con un acabado liso, brillante o similar a un espejo, particularmente para plásticos transparentes.

- Buena soldabilidadEl acero P20 se puede soldar con éxito para reparaciones y renovaciones, incluso en frío, si se toman las precauciones adecuadas. Esto facilita el mantenimiento y la reparación de moldes, prolongando la vida útil de herramientas costosas. Para más información sobre este tema, lea ¿Es soldable el acero P20?

- Versatilidad e idoneidad para diversas aplicacionesEl P20 es un acero versátil para moldes, utilizado en moldes de corte a máquina de todos los tamaños. Se utiliza ampliamente en moldes para inyección y compresión de plásticos. Además, se aplica en matrices de fundición a baja temperatura para aleaciones como estaño, zinc y plomo.

- Capacidad para tratamientos de endurecimiento de superficiesAunque el acero P20 ha sido preendurecido, su tener puesto La resistencia y la dureza se pueden mejorar aún más mediante tratamientos de carburación y nitruración.

- Disponible en secciones grandesEl acero P20 está disponible en piezas forjadas de gran tamaño, lo que lo hace adecuado para moldes de plástico masivos que pueden pesar varias toneladas métricas y ser muy gruesos.

- Costo-efectividad. En comparación con los grados de mayor aleación, el acero P20 ofrece un equilibrio favorable entre propiedades y costo. Es un alambre de relleno relativamente económico que contribuye aún más al ahorro en reparaciones.

Lo anterior es nuestro resumen de las ventajas del acero P20 en aplicaciones de moldeo. Esperamos que le sea útil. No dude en contactarnos si tiene alguna pregunta sobre el acero P20.

Obtenga una cotización competitiva para acero P20

Con más de 20 años de experiencia en forja, Aobo Steel es su socio de confianza para acero para herramientas P20 de alto rendimiento. Ofrecemos no solo materiales, sino también soluciones. Aproveche nuestro profundo conocimiento del sector y nuestra confiable cadena de suministro para el éxito de su proyecto.

✉Contáctanos rellenando el siguiente formulario.