Tempo estimado de leitura: 10 minutos

Principais conclusões

- Os aços H11 e H13 são ambos aços ferramenta para trabalho a quente da AISI, conhecidos por sua alta resistência e dureza em temperaturas elevadas.

- O H13 possui um teor de vanádio mais elevado, o que aumenta sua resistência ao desgaste em comparação com o H11, que oferece maior tenacidade.

- Ambos os aços requerem processos específicos de tratamento térmico, incluindo pré-aquecimento e resfriamento ao ar, para atingir o desempenho ideal.

- As aplicações variam: o H13 se destaca em ambientes de alto desgaste, enquanto o H11 é preferido onde a resistência é fundamental.

- A escolha entre o aço H11 e o H13 depende das necessidades específicas de resistência ao desgaste e tenacidade das aplicações.

Índice

H11 e H13 ambos os aços pertencem ao Instituto Americano do Ferro e do Aço (AISI) A série H de aços-ferramenta para trabalho a quente representa dois dos aços-ferramenta de cromo 5% mais utilizados. aços para ferramentas de trabalho a quente. Esses aços são materiais essenciais na fabricação, sendo sua principal vantagem a capacidade de manter excelente resistência e dureza mesmo sob condições de trabalho de alta temperatura.

Embora compartilhem semelhanças fundamentais em propriedades, diferenças sutis na composição química conferem a cada um vantagens de desempenho distintas. Portanto, em aplicações práticas, a escolha entre H11 e H13 deve ser feita cuidadosamente com base nas condições operacionais específicas do molde e na vida útil requerida.

Os aços H11 e H13 são ambos aços de média liga para endurecimento ao ar ou aços de ultra-alta resistência. Através de processos adequados de tratamento térmico, sua resistência ao escoamento 0,2% pode ser elevada a níveis muito superiores a 1380 MPa.

Classificação e Fundamentos Metalúrgicos Compartilhados

Os aços H11 e H13 pertencem à subcategoria de aços para trabalho a quente à base de cromo H10-H19. Compartilham a mesma base metalúrgica, caracterizada por um teor médio de carbono e altas concentrações de cromo e outros elementos formadores de carbonetos.

Equivalência entre as séries H11 e H13:

| EUA (AISI) | Alemanha (DIN / W-Nr.) | Japão (JIS) | China (GB) | Reino Unido (BS) |

| H11 | 1.2343(X37CrMoV5-1) | SKD6 | 4Cr5MoSiV | BH11 |

| H13 | 1.2344(X40CrMoV5-1) | SKD61 | 4Cr5MoSiV1 | BH13 |

Esses dois tipos de aço compartilham três características principais:

Em primeiro lugar, são utilizadas em aplicações de trabalho a quente em altas temperaturas, como a fundição sob pressão de ligas de alumínio, e podem suportar condições de operação de até 600°C.

Em segundo lugar, todos eles apresentam temperabilidade extremamente alta e são aços de endurecimento ao ar. Mesmo componentes de aço de grandes dimensões podem ser totalmente endurecidos de dentro para fora, simplesmente por resfriamento ao ar. O resfriamento ao ar minimiza as tensões internas e as alterações dimensionais geradas durante o tratamento térmico.

Por fim, tanto o H11 quanto o H13 são aços de têmpera secundária. Eles devem ser revenidos a temperaturas acima de aproximadamente 510 °C para precipitar carbonetos de liga finos, alcançando assim o desempenho ideal. Esse processo de revenido em alta temperatura não só alivia as tensões de forma eficaz, como também é a principal razão pela qual mantêm um desempenho estável durante a operação em altas temperaturas. O limite superior dessa operação em alta temperatura deve permanecer abaixo da temperatura de revenido.

Composição química: a diferença do vanádio

A principal diferença entre os aços H11 e H13 reside sobretudo no seu teor de vanádio (V).

Composição H11 e H13

| AISI | Nº UNS | DIN | C (%) | Mn (%) | Si (%) | Cr (%) | Ni (%) | Mo (%) | V (%) |

| H11 | T20811 | 1.2343 | 0.33-0.43 | 0.20-0.50 | 0.80-1.20 | 4.75-5.50 | 0,30 máximo | 1.10-1.60 | 0.30-0.60 |

| H13 | T20813 | 1.2344 | 0.32-0.45 | 0.20-0.50 | 0.80-1.20 | 4.75-5.50 | 0,30 máximo | 1.10-1.75 | 0.80-1.20 |

Essa diferença no teor de vanádio é o principal fator de diferenciação no desempenho mecânico:

| Recurso | H11 | H13 |

| Teor de Vanádio (V) | Inferior (ex.: 0,30–0,60%) | Mais elevado (ex.: 0,80–1,25%) |

| Resistência ao desgaste | Bom | Maior, devido aos carbonetos de V |

| Robustez | Maior/Melhor resistência à fratura | Ligeiramente inferior |

| Resistência à têmpera/dureza a quente | Excelente | Ligeiramente melhor |

Comparativo de desempenho: propriedades mecânicas

A principal diferença nas propriedades mecânicas entre H11 e H13 decorre de suas composições químicas, sendo que H13 possui um teor de vanádio mais elevado.

Em termos de resistência ao desgaste, o H13 oferece desempenho superior. Seu maior teor de vanádio promove a formação de abundantes carbonetos de vanádio duros, resultando em uma resistência ao desgaste que supera a do H11. Isso o torna altamente adequado para aplicações de alto desgaste, como forjamento a quente ou extrusão a quente.

No entanto, o H11 oferece tenacidade superior. As partículas de carboneto usadas no H13 para aumentar a resistência ao desgaste às vezes comprometem um pouco a tenacidade. Portanto, o H11 apresenta maior tenacidade à fratura.

Em termos de dureza térmica, ambos apresentam excelente desempenho, mas o H13 leva uma ligeira vantagem. Isso se deve, mais uma vez, ao fato de o H13 conter mais vanádio.

Tratamento térmico e fabricação de qualidade

Os processos de tratamento térmico para os aços H11 e H13 são cruciais para maximizar seu desempenho. Como ambos são aços de endurecimento ao ar, suas etapas fundamentais de tratamento térmico são muito semelhantes, incluindo tipicamente pré-aquecimento, austenitização, têmpera e revenido secundário ou terciário subsequente em alta temperatura.

Tratamento térmico padrão

Primeiro vem o pré-aquecimento, onde o aço deve ser pré-aquecido entre 790°C e 815°C antes de ser aquecido uniformemente até a temperatura final de forjamento ou austenitização.

A faixa de temperatura de austenitização para o aço H11 normalmente situa-se entre 995 °C e 1025 °C, enquanto a temperatura de austenitização para o aço H13 é ligeiramente superior, geralmente entre 995 °C e 1040 °C. Durante esta etapa, deve ser utilizada uma atmosfera protetora controlada para evitar a descarbonetação da superfície do aço.

O resfriamento rápido é a terceira etapa. Os aços H11 e H13 devem ser resfriados ao ar, pois esse método garante tensões residuais mínimas no material. Esses aços nunca devem ser resfriados em água.

Por fim, o revenido. Para obter endurecimento secundário e aliviar tensões, recomenda-se fortemente o revenido secundário ou múltiplos ciclos de revenido. A temperatura de revenido deve exceder o pico de endurecimento secundário de 510 °C. Especificamente para o aço H13, o revenido na faixa de 565 °C a 650 °C otimiza seu efeito de endurecimento secundário.

Aprimoramento da Qualidade (ESR/VAR)

Para atender às exigências de aplicações complexas, os aços das classes H11 e H13 são frequentemente submetidos a processos de fabricação especializados para aprimorar ainda mais sua qualidade e desempenho.

Em termos de melhoria da qualidade de fusão, esses dois aços frequentemente empregam tecnologias de fusão como: refusão por eletroescória (ESR) ou refusão por arco a vácuo (VAR).

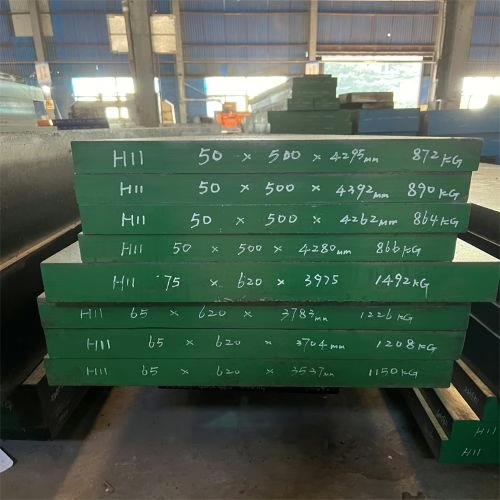

Em comparação com os aços fundidos convencionalmente, o processo ESR ou VAR aumenta significativamente a ductilidade e a tenacidade do material. O processo VAR, em particular, atinge níveis de impurezas extremamente baixos e alta uniformidade microestrutural. Para moldes de fundição sob pressão ou moldes de injeção de alto desempenho em aço H13, a refusão por ESR tornou-se um requisito comum de fabricação. Nossa empresa oferece materiais ESR H13 e H11.

Modificação de superfície

Para melhorar o desempenho da superfície, os aços H11 e H13 geralmente passam por tratamento de nitretação. A nitretação é um tratamento térmico químico que forma uma camada extremamente endurecida na superfície do aço. Os aços H11 e H13 atingem alta resistência interna e alta dureza superficial após a nitretação. O H13, em particular, apresenta excelente resposta à nitretação, com dureza superficial atingindo 1000-1200 HV. Além disso, a excepcional resistência do H13 ao revenido em altas temperaturas garante que seu núcleo interno mantenha sua alta resistência original, sem amolecimento durante o aquecimento de nitretação.

Critérios de Candidatura e Seleção

Ao escolher entre H11 e H13, a decisão envolve essencialmente equilibrar a alta resistência ao desgaste do H13 com a alta tenacidade do H11.

- Aplicações de Fundição Sob Pressão: Ambos são referências na indústria. O H13 possui a mais ampla gama de aplicações, sendo comumente utilizado para fundição sob pressão de ligas de alumínio, zinco e magnésio, enquanto o H11 é frequentemente utilizado para fundição sob pressão de alumínio e chumbo.

- Forjamento a quente e extrusão: O H13 é a opção mais versátil para matrizes de forjamento a quente. O H11 é comumente usado para punções e matrizes em forjamento de alumínio (HRC 44-48) ou para cilindros laminados a quente em pequenos lotes.

- Moldes de plástico: Ambos os materiais são adequados. O H13 é a melhor opção, especialmente o H13 refundido por ESR, que é a escolha preferencial para a fabricação de moldes de alta precisão e polimento, como lentes automotivas. O H11 é adequado para aplicações de moldagem de plástico em altas temperaturas, onde as temperaturas de operação excedem 300 °C.

- Componentes estruturais aeroespaciais: Ambos são ligas de ultra-alta resistência. O H11 é mais comumente usado em componentes de alta tensão, como trens de pouso de aeronaves e invólucros de foguetes, pois deve manter alta resistência em temperaturas elevadas. O H13 também foi amplamente utilizado no passado, mas sua aplicação nesse campo diminuiu com o surgimento de novos aços de alta tenacidade.

Resumo para Seleção:

Escolha H13 quando:

- Quando a principal exigência é alta resistência ao desgaste, o H13 contém níveis mais elevados de vanádio (V), permitindo a formação de carbonetos de vanádio mais dispersos e duros. Isso o torna superior ao H11 em ambientes de desgaste abrasivo, como extrusão a quente e forjamento de alta resistência ao desgaste.

- Quando se exige dureza a quente ideal e resistência ao revenimento, o H13 oferece estabilidade ligeiramente superior em temperaturas elevadas, preservando melhor a dureza e a resistência sob condições de alta temperatura.

- Para trabalhos a quente de uso geral e moldes de fundição sob pressão, o H13 continua sendo o aço ferramenta para trabalho a quente de uso geral mais utilizado, particularmente em aplicações de moldes de fundição sob pressão.

Escolha H11 quando:

- Quando se exige máxima resistência, o H11 oferece tenacidade à fratura e ductilidade superiores em comparação com o H13, tornando-o uma opção mais segura para aplicações que envolvem cargas de impacto, onde a prevenção de fissuras inesperadas no molde é crucial.

- Quando utilizado em componentes estruturais de alta resistência, o H11 resiste ao amolecimento e mantém alta resistência em temperaturas de até 540°C, sendo comumente usado em componentes aeroespaciais de alta tensão, como trens de pouso.

Dados suplementares

Reunimos dados confiáveis sobre H11 e H13, que esperamos serem úteis aos nossos leitores.

Comparação de outros parâmetros

| Fator | Aços para ferramentas H11 | Aços para ferramentas H13 |

| Dureza usual de trabalho, HRC | 38-55 | 40-53(Dureza do aço H13) |

| Profundidade de endurecimento | D | D |

| O mais fino tamanho de grão com dureza total, padrão Shepherd | 8 | 8 |

| Dureza da superfície como temperada, HRC | 53-55 | 51-54 |

| Dureza do núcleo (25 mm, ou 1 pol., de diâmetro redondo), HRC | 53-55 | 51-54 |

| Meio de resfriamento | A | A |

| Temperatura de endurecimento, °C (°F) | 995-1025 (1825-1875) | 995-1040 (1825-1900) |

| Alteração dimensional no endurecimento | L | L |

| Segurança no endurecimento | H | H |

| Suscetibilidade à descarbonetação | H | H |

| Dureza aproximada como laminado ou forjado, HB | 500 | 500 |

| Recozido Dureza, HB | 192-229 | 192-229 |

| Temperatura de recozimento, °C (°F) | 845-900 (1550-1650) | 845-900 (1550-1650) |

| Faixa de revenimento, °C (°F) | 540-650 (1000-1200) | 540-650 (1000-1200) |

| Temperatura de forjamento, °C (°F) | 1065-1150 (1950-2100) | 1065-1150 (1950-2100) |

Os aços ferramenta H11 e H13 compartilham muitas semelhanças em termos de suas propriedades mecânicas., tratamento térmico características e recursos de forjamento. A principal diferença está em sua faixa de dureza, sendo que o H13 oferece dureza um pouco mais alta para aplicações mais exigentes. A escolha entre esses dois aços depende dos requisitos específicos da aplicação pretendida, como o nível de resistência ao desgaste, a tenacidade e a estabilidade dimensional necessárias.

Propriedades de tração dos aços para ferramentas H11 e H13 em temperaturas elevadas

| Tipo de aço | Temperatura de teste (°C) | Temperatura de teste (°F) | Resistência à tração (MPa) | Resistência à tração (ksi) | Resistência ao escoamento (deslocamento de 0,2%) (MPa) | Resistência ao escoamento (deslocamento de 0,2%) (ksi) | Alongamento (50 mm) (%) | Redução de área (%) | Dureza à temperatura ambiente (HRC) Antes teste | Dureza à temperatura ambiente (HRC) Após teste |

| H11 | Quarto | Quarto | 1806 | 262 | 1482 | 215 | 10 | 35.8 | 50 | 50 |

| 150 | 300 | 1689 | 245 | 1358 | 197 | 10.1 | 36.1 | 50 | 50 | |

| 260 | 500 | 1600 | 232 | 1345 | 195 | 9.8 | 34.5 | 50 | 50 | |

| 345 | 650 | 1579 | 229 | 1317 | 191 | 10 | 35.2 | 50 | 50 | |

| 425 | 800 | 1510 | 219 | 1289 | 187 | 11.4 | 38.7 | 50 | 50 | |

| 480 | 900 | 1427 | 207 | 1145 | 166 | 12.2 | 38.9 | 50 | 50 | |

| 540 | 1000 | 1241 | 180 | 965 | 140 | 11 | 35.4 | 50 | 50 | |

| 595 | 1100 | 979 | 142 | 724 | 105 | 12.8 | 46.2 | 50 | 47 | |

| 650 | 1200 | 586 | 85 | 434 | 63 | 18.9 | 66.6 | 50 | 41 | |

| H13 | 480 | 900 | 1531 | 222 | - | - | 9 | 37 | 52 | - |

| 540 | 1000 | 1413 | 205 | - | - | 11 | 43 | 52 | - | |

| 595 | 1100 | 1193 | 173 | - | - | 15 | 49 | 52 | - | |

| 650 | 1200 | 814 | 118 | - | - | 22 | 59 | 52 | - |

Observação:

- O "-" nas colunas de resistência ao escoamento do aço H13 indica que os dados não estavam disponíveis.

- A coluna Dureza à temperatura ambiente (HRC) mostra os valores antes e depois do teste, separados por vírgula.

- Dados da Teledyne VASCO. Allegheny Ludlum Industries e Universal-Cyclops Steel Corp.

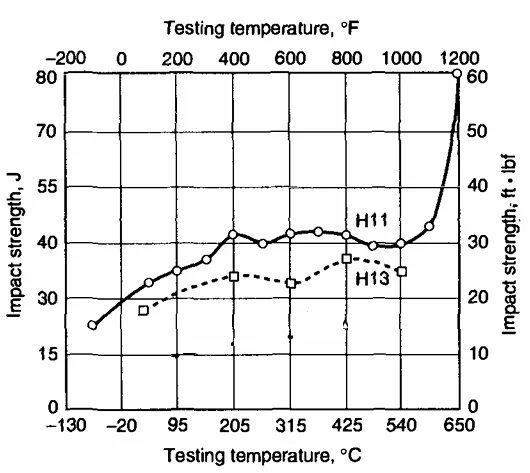

Resistência ao impacto CVN dos aços para ferramentas H11 e H13 em função da temperatura de teste.

Esse gráfico sugere que o H11 e o H13 se tornam mais resistentes ao impacto em temperaturas mais altas. Entretanto, o H13 é mais sensível às mudanças de temperatura, mostrando um aumento mais significativo na resistência ao impacto com o aumento da temperatura.