Nástrojová ocel D6 | 1.2436 | SKD2

AOBO STEEL – Trusted Global Tool Steel Supplier

Nástrojová ocel D6 je klasifikována pod systém AISI jako s vysokým obsahem uhlíku, s vysokým obsahem chrómu nástrojová ocel pro tváření za studena. Steels in this category typically feature a nominal chromium content of around 12%, which is fundamental to their performance characteristics. The specific properties are fine-tuned through variations in alloying elements, such as carbon, molybdenum, vanadium, and manganese.

1. Aplikace

- Dlouhá výrobní série vysekávacích matric

- Razníky pro tváření za studena a zemře

- Součásti nástrojů vystavené silnému otěru

- Aplikace, kde je zásadní zachování ostré hrany při delším používání

2. D6 Steel Composition

| uhlík (C) | Chrom (Cr) | Wolfram (W) | mangan (Mn) | křemík (Si) |

| 2.00 – 2.20% | 11.50 – 12.50% | 0.60 – 0.90% | 0.20 – 0.40% | 0.10 – 0.40% |

The D6 tool steel equivalent grades’ composition

| uhlík (C) | křemík (Si) | mangan (Mn) | Chrom (Cr) | Wolfram (W) | fosfor (P) | síra (S) | |

| Germany/W-Nr. 1.2436 (X210CrW12) | 2.00 – 2.30% | 0.10 – 0.40% | 0.30 – 0.60% | 11.0 – 13.0% | 0.60 – 0.80% | ≤ 0,030% | ≤ 0,030% |

| Japan/JIS SKD2 | 2.00 – 2.30% | 0.10 – 0.60% | 0.30 – 0.60% | 11.0 – 13.0% | 0.60 – 0.80% | ≤ 0,030% | ≤ 0,030% |

| China/GB Cr12W | 2.00 – 2.30% | ≤ 0,401 TP3T | ≤ 0,401 TP3T | 11.0 – 13.0% | 0.60 – 0.90% | ≤ 0,030% | ≤ 0,030% |

3. Properties of D6 Steel

3.1 Physical properties

| Hustota | Koeficient tepelné roztažnosti | Tepelná vodivost | Specifická tepelná kapacita |

| 7.67 g/cm³ | 10.8 µm/m°C (21-400°C) | 20.5 W/mK (20°C) | 0.460 J/g-°C (20°C) |

3.2 Hardness and Wear Resistance

Hlavní výhodou nástrojové oceli D6 je její velmi vysoká odolnost proti opotřebení. This stems directly from its high carbon and chromium content, which promotes the formation of hard chromium-rich carbides in the steel’s microstructure after heat treatment. Properly hardened and tempered, D6 typically achieves a hardness of between 54 a 61 HRC. Jeho odolnost proti opotřebení obecně převyšuje odolnost běžnějších Nástrojová ocel D2l, takže je vhodný pro aplikace, které vyžadují dlouhou životnost v abrazivních podmínkách.

3.3 Toughness

D6 má vysokou odolnost proti opotřebení, ale nižší houževnatostVe srovnání s ocelemi odolnými proti nárazu (jako je řada S) nebo jinými ocelemi pro práci za studena s nižším obsahem uhlíku (jako je řada A nebo D2) je nástrojová ocel D6 křehčí. Stejné tvrdé karbidy, které odolávají opotřebení, mohou ocel při nárazu učinit náchylnější k odštípnutí nebo praskání. Proto se nástrojová ocel D6 nedoporučuje pro aplikace s významným rázovým nebo rázovým zatížením.

3.4 Hardenability and Heat Treatment

D6 je a hluboce kalená ocel; může dosáhnout relativně rovnoměrné tvrdosti v celém průřezu, a to i u větších rozměrů. Obvykle se jedná o kalení v oleji třídy, i když může být vytvrzen vzduchem s určitou obětí na dosažitelné tvrdosti. Popouštění po kalení je zásadní pro zmírnění pnutí a dosažení požadované rovnováhy mezi tvrdostí a houževnatostí.

3.5 Dimensional Stability

Jako ocel kalitelná v oleji může D6 vykazovat větší rozměrové změny během tepelného zpracování ve srovnání s třídami kalitelnými na vzduchu, jako je nástrojová ocel D2. Pečlivá kontrola procesu tepelného zpracování je nezbytná, pokud jsou kritické úzké rozměrové tolerance.

3.6 Machinability and Grindability

Vzhledem k vysoké tvrdosti a značnému obsahu karbidů je uvažována ocel D6 náročnější na obrábění a broušení oproti méně legovaným ocelím nebo dokonce D2. To by mělo být zohledněno ve výrobních procesech a nákladech.

Interesting In D6 | 1.2436 Tool Steel? Please fill out the following form to contact us now!

4. D6 tool steel heat treatment

4.1 Předehřívání

Preheating reduces thermal shock, thereby lowering the risk of subsequent cracking or deformation. Preheating is typically performed at temperatures between 650°C and 760°C (1200°F and 1400°F). Ensure that the entire tool has reached the preheating temperature uniformly before calculating the soaking time. Based on our experience, the soaking time is 10–15 minutes.

4.2 Austenitizing (Hardening)

The purpose of this step is to transform the microstructure of the steel into austenit, preparing it for subsequent quenching. The temperature range is between 950°C and 1050°C (1740°F and 1920°F). The holding time is 1 hour per 25 mm (1 inch) of thickness. It is important to note that insufficient holding time may result in incomplete quenching, while excessive holding time may lead to grain growth and reduced toughness.

4.3 Quenching

This step involves transforming the austenite into hard martensite. D6 Tool Steel is an oil-hardening steel. Oil quenching provides a sufficiently fast cooling rate for hardening while being less harsh than water, which significantly reduces the risk of cracking and distortion.

The specific process involves quenching the workpiece in oil until it cools to room temperature or 65 °C (150°F).

Sometimes, air-quenching is also chosen, but the hardness after air quenching is relatively lower. If higher deformation requirements are specified, air quenching of D6 steel can be considered.

4.4 Temperování

The purpose of tempering is to reduce brittleness and increase toughness. A two-step tempering process is recommended to ensure maximum stress relief and dimensional stability.

The tempering temperature ranges from 150°C to 550°C (300°F to 1020°F). The soaking time is 2 hours per 25mm (1 inch) of thickness for each tempering cycle.

The tempering temperature determines the material’s final hardness. Higher tempering temperatures reduce the hardness of D6 steel but increase its toughness. The specific temperature should be determined based on actual application requirements.

Table of Hardness and Tempering Temperature for D6 Steel

| TEMPERING TEMPERATURE | Rockwell C |

| As quenched | 67 |

| 300°F / 150°C | 65 |

| 400°F / 205°C | 64 |

| 500°F / 260°C | 63 |

| 600°F / 315°C | 62 |

| 700°F / 370°C | 61 |

| 800°F / 425°C | 61 |

| 900°F / 480°C | 58 |

| 1000°F / 540°C | 55 |

4.5 Achieving Better Results and Avoiding Problems

Správné řízení procesu je zásadní pro dosažení úspěšného tepelného zpracování.

4.5.1 Dimensional Stability

To reduce the risk of deformation of D6 steel during quenching, the following precautions should be taken.

- Two preheating cycles can be performed.

- Ensure uniform heating during the austenitization process.

- Stir during oil quenching.

- Perform stress relief treatment after rough machining and before final heat treatment.

4.5.2 Stress Relief (Post-Hardening)

Stress relief treatment should be performed after heavy grinding, welding, or electrical discharge machining. The stress relief temperature should be 15°C to 30°C (25°F to 50°F) lower than the final tempering temperature. The holding time should be 1-2 hours per 25mm (1 inch) of thickness.

4.5.3 Common Heat Treatment Issues

- Praskání: Často způsobeno tepelným šokem (nedostatečným předehřátím nebo příliš silným kalením).

- Zkreslení: Způsobeno nerovnoměrným ohřevem/chlazením nebo vnitřním pnutím.

- Nedostatečná tvrdost: Výsledkem nesprávné austenitizační teploty/času nebo nedostatečného kalení.

4.6 Forging D6 tool steel

Slowly preheat to 900 °C (1650 °F). Forging should begin within the temperature range of 980 °C (1800 °F) to 1095 °C (2000 °F). Do NE forge below 900 °C (1650 °F). For larger cross-sections, heavier pieces, or rapid thinning, use the higher end of the temperature range; for smaller cross-sections or lighter thinning, use the lower end of the temperature range.

5. Srovnání s ostatními nástrojovými ocelmi

5.1 D6 vs. D2

Nástrojová ocel D2 and D6 tool steel are high-carbon, high-chromium cold-work tool steels known for wear resistance. D6 has slightly higher wear resistance at the cost of lower toughness and more complex/difficult heat treatment (oil quenching, higher distortion risk). D2 is more widely used due to its better balance of properties, especially its air-hardening capability and minimal distortion.

5.2 D6 vs. D3

- Obě jsou oceli s vysokým obsahem uhlíku, vysokým obsahem chrómu, v oleji kalitelné oceli známé pro svou výjimečně vysokou odolnost proti opotřebení.

- Mohou existovat drobné rozdíly ve složení (někdy W nebo V u nástrojové oceli D6).

- D3 heat treatment is complex than D6.

5.3 D6 vs. D7

- D7 obsahuje přidaný vanad, který potenciálně nabízí ještě vyšší odolnost proti oděru než nástrojová ocel D6.

- D7 má typicky nižší houževnatost než D6 a vyžaduje vyšší kalicí teploty.

6. Úvahy při výběru nástrojové oceli D6

Ocel D6 je vynikající volbou pro specifické aplikace vyžadující maximální odolnost proti opotřebení u nástrojů pro práci za studena. Pečlivě však zvažte:

- Nižší houževnatost: Nevhodné pro aplikace s vysokým dopadem.

- Zpracování: Náročnější na obrábění a broušení.

- Tepelné zpracování: Kalení oleje vyžaduje pečlivou kontrolu procesu pro rozměrovou stabilitu.

- Dostupnost: Může být méně snadno dostupná než nástrojová ocel D2.

7. Ekvivalentní známky

- DIN EN (Evropa): 1.2436 (X210CrW12)

- JIS (Japonsko): SKD2

- BS (UK): BD6

- ISO: X210CrW12

- GB(China): Cr12W

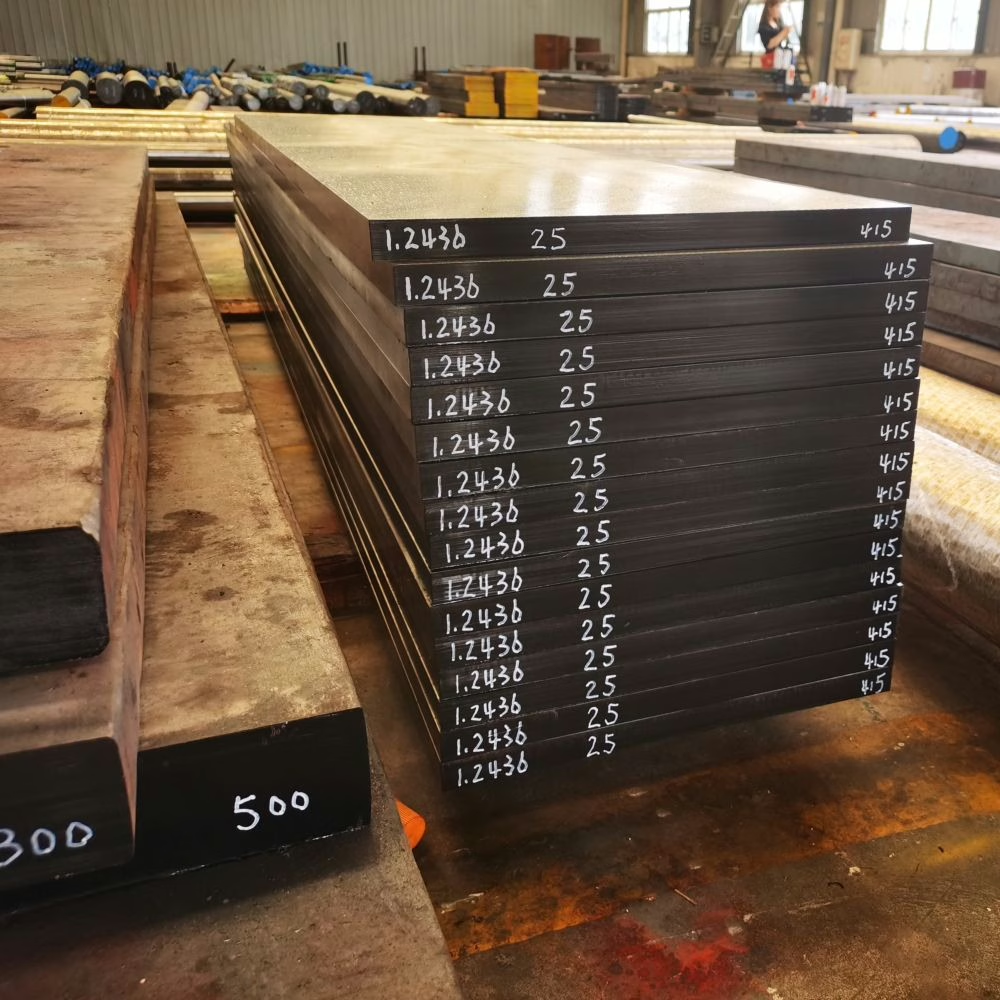

8. Supply forms and dimensions

The D6 tool steel that we supplied is in various forms, including round bars, sheet plates, slabs, flat bars, square bars, and blocks. The dimensions of the flat bar range from: width 20–600 mm × thickness 20–400 mm × length 1,000–5,500 mm. The dimensions of the round bar range from a diameter of 20–400 mm × a length of 1,000–5,500 mm. The block dimensions are obtained by cutting the flat bar.

For smaller sizes, such as round bars with a diameter less than 70 mm, we use the hot-rolled process. For sizes greater than 70 mm, we offer forged products.

UT testing: Sep 1921-84 D/d, E/e.

Surface Treatment: original black, peeled, machined/turned, polished, grounded, or milled surface finishes.

Inventory Status: We do not maintain a stock of D6 steel. We arrange production based on customer orders.

Delivery time: Electric Arc Furnace (EAF) materials are 30-45 days. ESR materials are approximately 60 days.

FAQ

D6 tool steel is a high-carbon, high-chromium tool steel alloyed with tungsten, primarily used for cold work applications. It is characterized by high compressive strength, high wear resistance, high surface hardness, and good hardening stability. It is also known as SKD2 steel and DIN 1.2436 steel.

D6 tool steel is characterized by excellent resistance to wear and abrasion, high compressive strength, high surface hardness, and good hardening and dimensional stability. Its robust carbide structure provides prolonged performance and reduced maintenance even under extreme stress.

AISI D6 tool steel is equivalent to JIS SKD2 in Japan and DIN 1.2436 (also X210CrW12) in Germany/UK/France. It is also referred to as UNS T30406.

D6 tool steel has a density of 7.67 g/cm³ (0.277 lb/in³). Its thermal expansion coefficient is 10.8 µm/m°C (6 µin/in°F) at 21-400°C, and its thermal conductivity is 20.5 W/mK (142 BTU.in/hrft².°F) at 20°C. It also has a specific heat capacity of 0.460 J/g-°C (0.110 BTU/lb-°F) at 20°C.

D6 tool steel exhibits a compressive strength of 1320 MPa (191000 psi) and a modulus of elasticity of 194 GPa (28100 ksi). Its Rockwell C hardness is 46 HRC in certain conditions, but can reach 55-62 HRC after heat treatment.

D6 tool steel is widely used for forming tools, molds for abrasive plastics and ceramics, and long-run press tools. It is also suitable for blanking dies, shearing tools for hard materials, stamping tools, scraping tools, woodworking tools, drawing tools, and machine knives. Specific uses include blanking dies for cutting sheets up to 2mm thick, paper and plastic blades, and extrusion dies for metals, plastics, and rubber.

Yes, D6 tool steel is used for outdoor fixed blades. A knifemaker noted that D6, being a super high-quality Tungsten alloyed tool steel, provides incredible edge retention due to its Tungsten carbides. While it can be heat-treated to 62 HRC, tempering it to 58 HRC makes it much tougher and a better daily tool for knives.

Yes, D6 tool steel is used for molds for abrasive plastics and also specifically for injection molds requiring high precision and wear resistance.

Yes, D6 tool steel is commonly used for blanking dies, shearing tools for hard materials, and blanking and shearing tools in general. It is suitable for cutting sheets up to 2mm thick and for cold shear blades for paper, plastic, cardboard, and metal.

D6 tool steel is heated slowly and uniformly to 700°C (1292°F), and then more rapidly to 900-1050°C (1652-1922°F) for forging. After forging, it should be cooled slowly to room temperature in a furnace.

D6 tool steel is annealed at 800-840°C (1472-1544°F) and then cooled slowly in a furnace. Alternatively, it can be heated at 50-100°C (122-212°F) per hour to 830-870°C (1526-1598°F), soaked for 1 hour per 25.4 mm (1 inch), and then cooled slowly in a furnace or controlled environment. The hardness after annealing will be approximately 225 Brinell.

Stresses from D6 tool steel can be eliminated before hardening by heating up to 650-700°C (1202-1292°F), especially if machining operations have been heavy. The steel is then allowed to cool slowly.

D6 steel is first pre-heated slowly to 750-800°C (1382-1472°F) and thoroughly soaked. Heating then continues until a final hardening temperature of 950-980°C (1742-1796°F), or 940-1000°C. It is then followed by air or oil quenching, or quenching in a warm bath or salt bath. Vacuum (high-speed gas) hardening is also considered a perfect method.

D6 tool steel is heated uniformly and thoroughly at the selected tempering temperature. Double tempering can also be carried out with intermediate cooling to room temperature. Tempering temperatures typically range from 500-600°C (932-1112°F), or specific temperatures like 100°C (resulting in 63 HRC) up to 600°C (resulting in 48 HRC). The final hardness of D6 tool steel after heat treatment can range from 55 to 62 HRC.

In hard turning of AISI D6 steel, machining parameters like speed, feed, and depth of cut affect output responses such as surface roughness, cutting force, crater wear length, crater wear width, and flank wear. Abrasion and adhesion are dominant wear mechanisms, with tool wear increasing with speed, and cutting force increasing rapidly at higher speeds (70-90 m/min). Higher feed and depth of cut values also result in more surface damage and higher cutting force. Machine learning models can be used to test, evaluate, and optimize these machining parameters to predict characteristics like surface roughness.

D6 tool steel has better through-hardening properties and dimensional stability compared to D3 steel.

Get a Competitive Quote for D6 Tool Steel

With over 20 years of forging expertise, Aobo Steel is your trusted partner for high-performance D6 tool steel. We provide not just materials, but solutions. Leverage our deep industry knowledge and reliable supply chain for your project’s success.

✉ Contact us by filling out the form below.

Prozkoumejte naše další produkty

D2/1.2379/SKD11

D3/1.2080/SKD1

D6/1,2436/SKD2

A2/1.23663/SKD12

O1/1.2510/SKS3

O2/1,2842

S1/1,2550

S7/1,2355

DC53

H13/1.2344/SKD61

H11/1.2343/SKD6

H21/1,2581/SKD7

L6/1.2714/SKT4

M2/1.3343/SKH51

M35/1.3243/SKH55

M42/1.3247/SKH59

P20/1,2311

P20+Ni/1,2738

420/1.2083/2Cr13

422 z nerezové oceli

Ložisková ocel 52100

Nerezová ocel 440C

4140/42CrMo4/SCM440

4340/34CrNiMo6/1,6582

4130

5140/42Cr4/SCR440

SCM415