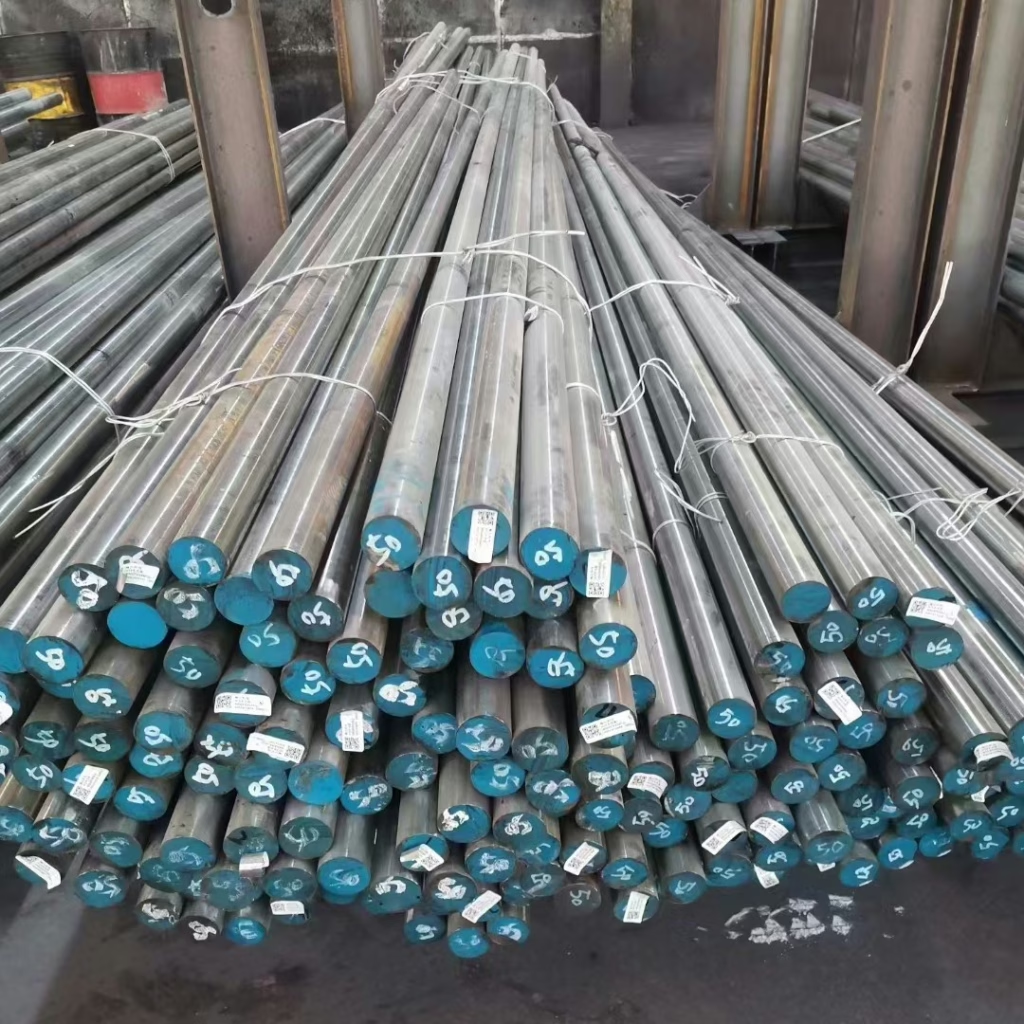

H10 Tool Steel | 1.2365 | SKD7

AOBO STEEL – Trusted Global Tool Steel Supplier

H10 tool steel is a chromium-based hot-work tool steel. The equivalent grades are DIN (Germany) 1.2365, JIS (Japan) SKD7, and GB (China) 4Cr3Mo3SiV.

1. H10 Tool Steel Chemical Composition1

| C | Mn | Si | P | S | Cr | Mo | Others |

| 0.35-0.45% | 0.20-0.70% | 0.80-1.25% | 0.03% | 0.03% | 3.00-3.75% | 2.00-3.00% | V 0.25-0.75%; Ni+Cu 0.75% |

2. Mechanical and Physical Properties of H10 Tool Steel

Alloying elements in H10 tool steel impart a unique set of mechanical and physical properties, making it suitable for challenging hot-work environments.

2.1 Hardness Capabilities

The hardness of H10 tool steel is a critical factor in its performance:

- Annealed Hardness: In its annealed (softened) state, H10 typically exhibits a hardness range of 192-229 HB, facilitating easier machining.

- Quenched Hardness: Following appropriate heat treatment, H10 can achieve a quenched hardness of approximately 56-59 HRC.

- Hot Hardness: H10 demonstrates medium (rated C) hot hardness. Notably, in high-temperature working environments over long periods, MOD H10 tool steel maintains its hardness better than H11 tool steel.

2.2 Hardenability and Heat Treatment Response

H10 is a deep-hardening steel that can achieve uniform hardness across a wide range of cross-sections. Its hardening factor (D1) is approximately 5 inches. As an air-hardening grade, H10 allows for martensite formation upon air-cooling, which contributes to minimal distortion during the heat treatment process.

2.3 Toughness and Impact Resistance

H10 tool steel offers excellent toughness, generally rated as Good (or D category). Chromium hot-work steels like H10 offer good toughness and shock resistance, which are advantageous for many hot-work operations. While some comparative data might suggest slightly lower toughness than H11 or H13, H10 remains a robust choice for applications requiring impact strength.

2.4 Wear Resistance

The wear resistance of H10 tool steel is typically rated as Fair (C/D category), with some sources classifying it as medium-high, often outperforming H11 and H13 tool steel in this aspect. Good abrasion resistance is a vital property for dies used in demanding processes like hot forging.

2.5 Performance at Elevated Temperatures

A standout feature of H10 tool steel is its ability to maintain structural integrity at high temperatures:

- Hot Strength: It exhibits good resistance to softening, retaining high hardness even at temperatures up to 500-550°C. This “red hardness” is essential for tools operating at high speeds or in direct contact with hot metal.

- Tempering Resistance: H10 possesses medium-high tempering resistance, potentially exceeding that of H11 or H13 under certain operational conditions.

2.6 Thermal Properties

H10 tool steel is well-suited for applications involving thermal cycling:

- Thermal Fatigue and Heat Checking Resistance: H10 has good resistance to thermal fatigue and heat checking, which are common failure modes in hot-work tooling.

- Thermal Conductivity: With a chromium content of around 3%, H10 has a higher thermal conductivity (approximately 32 W/m·K) compared to steels like H11 or H13 (which have ~5% Cr and ~26 W/m·K). This enhanced thermal conductivity is beneficial for applications requiring efficient heat dissipation from the tool’s surface.

2.7 Dimensional Stability

Being an air-hardening steel, H10 offers the advantage of low distortion during heat treatment, ensuring that tools maintain their intended shape and tolerances.

2.8 Machinability

When properly annealed, H10 tool steel has a machinability rating generally considered Good (C category), allowing for effective shaping and preparation of tools.

Fill out the following form to contact us for the latest H10 tool steel quotation!

3. H10 Tool Steel Heat Treatment

H10 tool steel, a robust chromium-based hot-work tool steel from the H-series, is engineered for demanding applications such as hot forging, extrusion, and die casting. Its performance under extreme operational temperatures, typically 315°C to 650°C (600°F to 1200°F), relies heavily on precise heat treatment.

3.1 The Critical Steps in H10 Heat Treatment

Achieving peak performance from H10 tool steel involves several distinct and vital stages. Each step must be carefully controlled to develop the desired microstructure and mechanical properties.

3.2 Annealing

Annealing is typically the first step for H10 tool steel. It’s crucial for softening the steel for easier machining and creating a uniform microstructure for subsequent heat treatments.

- Purpose: To soften the steel for machinability and create microstructural uniformity.

- Recommended Temperature: 845°C to 900°C (1550°F to 1650°F).

- Cooling Procedure: A slow cool at a rate of approximately 22°C per hour (40°F per hour) is advised.

- Target Hardness: The aim is to achieve an annealed hardness between 192 and 229 HB.

- Resulting Microstructure: A properly annealed H10 will exhibit spheroidized carbides dispersed within a ferrite matrix, ideal for effective austenite formation and grain refinement during hardening.

3.3 Preheating

Preheating is a vital stage before hardening. It significantly reduces thermal shock, minimizing distortion or cracking when the tool enters the high-temperature furnace.

- Purpose: To reduce thermal shock, lessen distortion/cracking risks, relieve machining stresses, and decrease time in the high-heat austenitizing furnace.

- Typical Temperature: Around 815°C (1500°F) is common. Staged preheating can also be beneficial.

- Duration: Ensure the entire cross-section of the tool is uniformly heated.

3.4 Austenitizing (Hardening)

Austenitizing (or hardening) involves heating H10 tool steel to a precise high temperature. This transforms its microstructure to austenite and dissolves essential alloy carbides, crucial for hardness and secondary hardening characteristics during tempering.

- Purpose: To transform the steel’s structure to austenite and dissolve necessary alloying elements (like Chromium, Molybdenum, and Vanadium) into solid solution.

- Recommended Temperature: Generally between 1010°C and 1040°C (1850°F and 1900°F).

- Holding Time: Hold at temperature only long enough to heat completely through (typically 15-40 minutes after reaching temp). Avoid prolonged soaking for H10. Austenitizing temperature affects dissolved carbides, Ms temperature, and retained austenite.

3.5 Quenching

After austenitizing, quenching rapidly cools the steel, transforming austenite into martensite – the hard, desirable microstructure.

- Purpose: To rapidly cool the steel, transforming austenite into a hard martensitic structure.

- Recommended Quench Medium: Air quenching is preferred for H10 (an air-hardening grade), minimizing residual stresses and dimensional changes.

- Alternatives for Large Sections: For very large sections, an air blast or oil quench may be necessary.

- Critical Note: H10 tool steel should never be water quenched.

- Optional Method: A salt bath quench (around 540-595°C or 1000-1100°F), followed by air cooling, is also viable.

- Resulting Microstructure: Primarily martensite with some retained austenite.

3..6 Tempering

Tempering is the final, indispensable step after quenching. Hardened H10 is stressed and can be brittle; tempering relieves these stresses and significantly improves toughness.

- Purpose: To relieve internal stresses, transform retained austenite, precipitate fine alloy carbides for secondary hardening (enhancing hot strength), and improve toughness.

- Timing: Temper as soon as possible after quenching (ideally before reaching room temperature) to prevent cracking.

- Typical Temperature Range: 550°C to 650°C (1020°F to 1200°F). H10 shows a secondary hardening peak around 540°C (1000°F).

- Multiple Tempers: A Minimum of two (often up to four) tempering cycles are essential for H10 to maximize retained austenite transformation and optimize toughness.

- Soak Time: Each temper should involve a soak time of 2 to 4 hours.

- Target Working Hardness: Typically 38 to 54 HRC, depending on the application.

3.7 Summary of H10 Tool Steel Heat Treatment Parameters

For quick reference, the key parameters for H10 tool steel heat treatment are:

| Process Step | Temperature Range | Key Considerations |

| Annealing | 845-900°C (1550-1650°F) | Slow cool approx. 22°C/h (40°F/h). Target: 192-229 HB. |

| Preheating | ~815°C (1500°F) | Heat uniformly throughout. |

| Austenitizing | 1010-1040°C (1850-1900°F) | Hold 15-40 mins after reaching temp. Avoid prolonged soaking. |

| Quenching | Air quench (recommended). Salt bath: 540-595°C. | Never water quench. Oil or air blast for large sections. |

| Tempering | 550-650°C (1020-1200°F) | Temper immediately after quenching. 2-4 cycles, 2-4 hours each. Target: 38-54 HRC. |

3.8 Enhancing H10 Tool Steel with Surface Treatments

To further boost wear resistance, surface treatments like nitriding can be applied to H10 tool steel.

- Nitriding: This process introduces nitrogen into the steel’s surface, creating an extremely hard outer layer (often exceeding 1000 HV).

- Benefits: Significantly improves wear resistance and anti-galling properties.

- Core Properties: Nitriding is typically performed around 540°C, often below or within H10’s tempering range. This hardens the surface without negatively affecting the core toughness and strength established by prior heat treatment.

4. Applications

H10 tool steel’s balanced properties make it ideal for diverse hot die work applications, optimizing tooling choices for high-temperature metal forming operations.

4.1 Hot Forging: Crafting Durable Dies and Tools with H10

In hot forging, H10 tool steel demonstrates its value, particularly for press forging dies experiencing prolonged contact with heated workpieces.

Its capabilities include:

- Dies for forging aluminum, magnesium, copper, brass, and steel.

- Punches and dies for aluminum forging (often heat-treated to 44-48 HRC), where H10 serves as a reliable alternative to H11 and H13.

The toughness and hot hardness of H10 tool steel ensure longevity and consistent performance in these demanding forging environments.

4.2 Hot Extrusion: Optimizing Tooling with H10’s Resilience

H10 tool steel is a frequently specified material for hot extrusion tooling across a range of metals.

Key H10 tool steel applications in this area include:

- Extrusion Dies: For aluminum, magnesium, copper, brass, and steel.

- Mandrels: H10 is particularly suitable for hot extrusion mandrels, especially with copper alloys, due to its wear resistance and strength at temperature.

- Ancillary Tooling: Dummy blocks, backers, and die rings for aluminum and magnesium extrusion processes also benefit from H10’s properties.

4.3 Die Casting: H10 for High-Temperature Copper Alloy Molds

While H11, H12, and H13 are common for aluminum and magnesium die casting, H10 tool steel is preferred for applications involving higher temperature alloys.

- Copper Casting Dies: H10 is specifically recommended for copper casting dies. Its ability to effectively retain hardness at the elevated temperatures of copper alloy casting makes it the preferred choice.

4.4 Enhanced Performance with Modified H10 (H10 mod)

Modified H10 (H10 mod) offers a distinct advantage in thermal conductivity (approx. 32 W/m·K vs. 26 W/m·K for H11/H13). This superior heat dissipation is critical in several H10 tool steel applications:

- Heavily Water-Cooled Tools: Effective in smaller tools (<100mm thick) requiring rapid heat extraction.

- High-Speed Presses: Used in equipment like Hatebur presses where thermal management is key for short cycle times.

- Press-Hardening Automotive Components: H10 mod is increasingly used for tools in press-hardening (hot stamping). The die’s efficient heat extraction is crucial for achieving the desired martensitic transformation in the part.

4.5 H10 Tool Steel Applications Summary

The table below outlines common H10 tool steel applications and the key properties that make it suitable for each:

| Application Category | Specific H10 Tool Steel Uses | Key H10 Properties Leveraged | Target Materials |

| Hot Forging | Press forging dies, general forging tools, punches | Hot hardness, toughness, wear resistance | Al, Mg, Cu, Brass, Steel |

| Hot Extrusion | Extrusion dies, mandrels (esp. for copper alloys), dummy blocks, backers | Hot hardness, wear resistance at high temp, toughness | Al, Mg, Cu, Brass, Steel |

| Die Casting | Dies specifically for copper casting | Excellent high-temperature hardness retention | Copper alloys |

| Structural Components | Heavily water-cooled tools, high-speed press tools,and press-hardening tools | High strength, toughness | Various |

| Modified H10 (H10 mod) | Heavily water-cooled tools, high-speed press tools, press-hardening tools | High thermal conductivity, hot hardness, good toughness | Various (heat extraction) |

5. H10 tool steel equivalent grades

- DIN (Germany): 1.2365 (also known as 32CrMoV12-28)

- AFNOR (France): 32 DCV 28 or 32CDV12-28

- JIS (Japan): SKD7

- BS (British Standard): BH10

- UNS (Unified Numbering System): T20810

- GB(China): 4Cr3Mo3SiV

- Bringas, J. E. (Ed.). (2004). Handbook of comparative world steel standards (3rd ed.). ASTM International. ↩︎

Looking for Premium H10 Tool Steel?

With over 20 years of forging expertise, Aobo Steel delivers top-quality H10 tool steel tailored to your exact specifications. Our experienced team is ready to provide you with the best material solutions and technical support.

Contact us today! Please fill out the form below to get a personalized quote or expert consultation.