El acero para herramientas M2 es un acero para herramientas de alta velocidad, muy versátil y de uso general, que proporciona un buen equilibrio entre tenacidad, resistencia al desgaste, dureza en caliente y tratabilidad térmica, lo que lo hace adecuado para un amplio espectro de aplicaciones de corte, conformado y estructurales.

1. Aplicaciones1

- Herramientas de corte de uso general

- Herramientas de corte de un solo punto: Pueden mecanizar una amplia gama de materiales, incluidos acero forjado, acero fundido, hierro fundido, latón, bronce, cobre y aluminio.

- Ejercicios: El material M2 es la opción universal para taladros de uso general.

- Fresas: Más de 70% de fresas de mecanizado libre están hechas de material M2.

- Sierras: El acero para herramientas de alta velocidad M2 es un material de sierra de uso general.

- Otras aplicaciones: El acero de alta velocidad M2 se utiliza como material para núcleos y expulsores en herramientas de moldeo por inyección de plástico. También se utiliza en aplicaciones estructurales, como elementos de maquinaria, levas, ejes, husillos, engranajes y ruedas dentadas.

2. Composición del acero M22

| Elemento | Carbono (C) | Cromo (Cr) | Molibdeno (Mo) | Tungsteno (W) | Vanadio (V) | Silicio (Si) | Manganeso (Mn) | Fósforo (P) | Azufre (S) |

| Composición (%) | 0.78-0.88 | 3.75-4.50 | 4.50-5.50 | 5.50-6.75 | 1.75-2.20 | 0.20-0.45 | 0.15-0.40 | ≤0.03 | ≤0.03 |

3. Propiedades del acero para herramientas M2

El acero para herramientas M2 es un pilar fundamental en la familia de aceros de alta velocidad (HSS) y, por muchas buenas razones, es una opción popular para una amplia gama de aplicaciones exigentes. Este HSS a base de molibdeno, parte de la serie "M", ofrece una combinación fiable de dureza, resistencia al desgaste y tenacidad, lo que lo convierte en un acero versátil. Para más información sobre este tema, consulte Propiedades del acero para herramientas M2.

3.1 Dureza

El Dureza del acero para herramientas M2 Es muy alta y, mediante temple y revenido, su dureza de trabajo varía entre 60 y 65 HRC.

3.2 Resistencia al desgaste

Resistencia al desgaste extremadamente alta.

3.3 Dureza en caliente (resistencia al revenido)

Buena dureza térmica, lo que significa que puede mantener su dureza y resistencia incluso en condiciones de trabajo a alta temperatura. Si bien algunos grados de acero rápido (HSS) especializados pueden ofrecer mayor dureza en caliente, el material M2 ofrece un rendimiento fiable en entornos típicos de herramientas de alta temperatura.

3.4 Dureza

El acero M2 posee una alta dureza y resistencia al desgaste, a la vez que mantiene una buena tenacidad. El acero para herramientas M2 producido mediante procesos de pulvimetalurgia (P/M) presenta mayor tenacidad.

3.5 Propiedades físicas

| Propiedad | Valor |

| Densidad | 8138 kg/m³ (0,294 lb/pulg³) |

| Peso específico | 8.14 |

| Módulo de elasticidad | 30 x 10⁶ psi (207 GPa) |

| Maquinabilidad | 50-60% de un acero al carbono 1% |

3.6 Propiedades mecánicas

| Propiedad | Valor |

| Dureza (Rockwell C) | 60-65 |

| Resistencia a la tracción | 760-2.150 MPa (110.000-310.000 psi) |

| límite elástico | 3.250 MPa (471.000 psi) |

| Resistencia a la compresión (templado a 300°F) | 3.250 MPa (471.000 psi) |

| Módulo de elasticidad (Módulo de Young) | 200-207 GPa (29-30 x 10⁶ psi) |

| Módulo de cizallamiento | 77 GPa (11 x 10⁶ psi) |

| Relación de Poisson | 0.29 |

| Resistencia al impacto | 67 J/cm² |

| Pérdida por abrasión (según endurecimiento; ASTM G65) | 25,8 mm³ |

¿Le interesa el acero para herramientas M2? ¡Rellene el siguiente formulario para contactarnos de inmediato!

4. Tratamiento térmico

El acero M2 solo puede alcanzar el rendimiento requerido mediante un tratamiento térmico adecuado. El objetivo principal de Tratamiento térmico del acero para herramientas M2 consiste en transformar el acero M2 de un estado recocido y ablandado (compuesto principalmente de ferrita y carburos de aleación) a una estructura martensítica endurecida y revenida, en la que los carburos se distribuyen en una posición óptima para cumplir con los requisitos de rendimiento de corte necesarios.

La secuencia típica de tratamiento térmico para acero para herramientas M2 implica las siguientes etapas:

4.1 Precalentamiento

El precalentamiento de los materiales debe realizarse por etapas para minimizar el riesgo de choque térmico, especialmente cuando existen diferencias significativas en la sección transversal de las piezas. Si el horno se calienta primero a... 650 °C (1200 °F)Podemos colocar piezas M2 en la parte superior del horno para eliminar el frío y luego colocarlas en él. Esto ayuda a reducir el choque térmico y el riesgo de agrietamiento. Posteriormente, se colocan en el horno y se mantienen allí durante unos 10 a 12 minutos.

4.2 Endurecimiento(Austenitización)

La temperatura de endurecimiento del acero para herramientas M2 normalmente varía entre 1190 °C a 1220 °C (2175 °F a 2225 °F)Algunas referencias citan temperaturas de hasta 1230 °C (2250 °F). El tiempo de remojo a la temperatura de endurecimiento final del acero rápido M2 es relativamente corto, de tan solo unos minutos, dependiendo del tamaño de la pieza y la eficiencia del horno.

4.3 Apagado

El temple El medio puede ser aire, aceite o sal. El temple en aceite funciona bien para piezas de acero M2 con una sección transversal de hasta aproximadamente 1 a 1,5 pulgadas (25-38 mm)La transformación martensítica comienza aproximadamente 316 °C (600 °F) y se completa aproximadamente 93 °C (200 °F)Recomendamos enfriar las piezas M2 a aproximadamente 65 °C (150 °F) después del enfriamiento, para luego proceder al siguiente paso de templado.

4.4 Templado3

El revenido se realiza en el acero rápido M2 después del temple para aliviar las tensiones internas, mejorar la tenacidad y promover la dureza secundaria. Esto implica recalentar el acero a una temperatura intermedia inferior a su temperatura crítica de transformación.

El acero para herramientas de alta velocidad M2 requiere de 2 a 4 ciclos de revenido a una temperatura de al menos 540 °C (1000 °F), típicamente 3 ciclos.

Por ejemplo, después de la austenización a 1230 °C (2250 °F), el primer ciclo de revenido se realiza a 565 °C (1050 °F), seguido del segundo a 550 °C (1025 °F) y el tercero a 540 °C (1000 °F).

Para cada ciclo de revenido, el tiempo de permanencia es de 2 horas por cada 25 mm (pulgada) de la sección transversal más gruesa. Tras el primer revenido, la pieza de acero M2 debe enfriarse completamente a temperatura ambiente antes de realizar el siguiente revenido.

El templado del material M2 sirve para transformar el material retenido. austenita en fresco martensita, lo que provoca la precipitación de carburos complejos y contribuye significativamente a la dureza secundaria del acero. Los ciclos de revenido múltiples refinan la microestructura, mejoran la resistencia al desgaste y alivian aún más las tensiones.

Es importante tener en cuenta que el acero M2 no debe subtemplarse.

Además, recomendamos realizar un revenido de alivio de tensiones después de procesos posteriores como el esmerilado, la soldadura o el mecanizado por descarga eléctrica (EDM), con la temperatura de revenido establecida entre 14 y 28 °C (25 y 50 °F) por debajo de la temperatura de revenido final.

Tabla de relación dureza-temperatura de revenido para acero M2

| Temperatura de revenido | Rockwell C |

| Como se apagó | 65 |

| 900 °F/480 °C | 64 |

| 950 °F/510 °C | 65 |

| 1000 °F/540 °C | 65 |

| 1050 °F/565 °C | 64 |

| 1100 °F/595 °C | 62 |

| 1150 °F/620 °C | 58 |

| 1200 °F/650 °C | 52 |

5. Calificaciones equivalentes

- EE. UU. (AISI/ASTM): M2 (Esta es la designación principal)

- Alemania (DIN/W-Nr): 1.3343, HS6-5-2

- Japón (JIS): SKH51

- Gran Bretaña (BS): BM2

- China (GB): W6Mo5Cr4V2

- ISO: HS 6-5-2

- Francia (AFNOR): Z85WDCV06-05-04-02

- Suecia (SS): 2722

- Rusia (GOST): R6M5

6. Acero D2 vs. acero M2

En la producción industrial, a menudo comparamos Acero para herramientas D2 y acero para herramientas M2. Los datos comparativos de estos dos aceros se proporcionan en la siguiente tabla como referencia.

| Propiedad | Acero D2 | Acero M2 |

| Tipo | Acero para herramientas trabajado en frío | Acero rápido |

| Composición | C: 1,40-1,60%, Cr: 10,00-13,00%, Mo: 0,70-1,20%, V: 0,90%, Mn: 0,60%, Si: 0,60%, Fe: Equilibrio | C: 0,80-1,00%, W: 5,50-6,50%, Mo: 4,50-5,50%, Cr: 3,75-4,50%, V: 1,75-2,25%, Mn: 0,15-0,40%, Si: 0,20-0,45%, Fe: Equilibrio |

| Dureza (HRC) | 55-62 | 62-65 |

| Resistencia al desgaste | Excelente (temperatura ambiente) | Excelente (altas temperaturas) |

| Dureza | Bueno, mejor para el trabajo en frío | Buena, adecuada para corte a alta velocidad |

| Resistencia a la corrosión | Justo, semi-inoxidable | Pobre |

| Resistencia al calor | Pobre | Excelente |

| Maquinabilidad | Feria | Pobre |

| Coste | Moderado | Más alto |

| Usos típicos | Matrices, punzones, cuchillas de cizalla | Brocas, fresas, machos |

Para obtener más información, lea ¿Cuál es la diferencia entre el acero para herramientas D2 y M2?

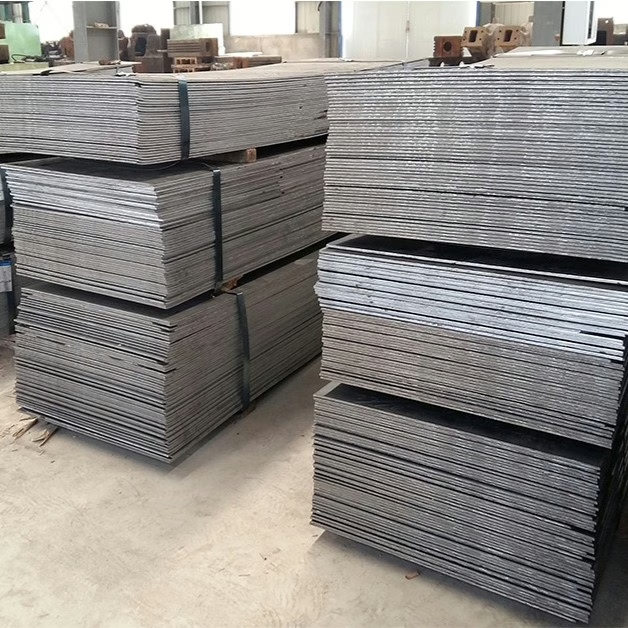

7. Formas y dimensiones de suministro

El acero para herramientas M2 que suministramos está disponible en diversas formas, incluyendo barras redondas, chapas, losas, barras planas, barras cuadradas y bloques. Las dimensiones de las barras planas varían de: ancho 20–600 mm × espesor 20–400 mm × longitud 1000–5500 mm. Las dimensiones de las barras redondas varían de 20–400 mm de diámetro × longitud 1000–5500 mm. Las dimensiones de los bloques se obtienen cortando la barra plana.

Para tamaños más pequeños, como barras redondas con un diámetro inferior a 70 mm, utilizamos el proceso de laminado en caliente. Para tamaños superiores a 70 mm, ofrecemos productos forjados.

Pruebas UT: septiembre de 1921-84 D/d, E/e.

Tratamiento de superficie: acabados superficiales originales negros, pelados, mecanizados/torneados, pulidos, rectificados o fresados.

Estado del inventario: No tenemos existencias de acero M2. Organizamos la producción según los pedidos de los clientes.

Tiempo de entrega: Los materiales para horno de arco eléctrico (EAF) son de 30 a 45 días.

- Roberts, G., Krauss, G., y Kennedy, R. (1998). Aceros para herramientas: 5.ª edición. ASM Internacional. ↩︎

- Bringas, JE (Ed.). (2004). Manual de normas comparativas mundiales del acero (3ª ed.). ASTM Internacional. ↩︎

- ASM Internacional. (1989). Manual de ASM, Volumen 16: Mecanizado. ASM Internacional. ↩︎

Preguntas frecuentes

El acero para herramientas M2 es un acero rápido de tungsteno-molibdeno (HSS) con una composición equilibrada, considerado el HSS industrial estándar y más popular a nivel mundial. Es una aleación de acero con alto contenido de carbono y molibdeno.

El acero para herramientas M2 es muy valorado por su excelente resistencia a la abrasión, alta dureza y buena tenacidad. Además, posee una resistencia al desgaste y dureza al rojo equilibradas. Su densidad es de 8138 kg/m³ (0,294 lb/in³) y su módulo de elasticidad es de 207 GPa (30 x 10⁶ psi).

La “dureza roja” se refiere a la capacidad del acero para herramientas M2 de mantener una alta dureza y filos afilados incluso en condiciones de alta tensión y alta temperatura.

Sí, el acero para herramientas M2 se clasifica como un acero de alta aleación porque sus elementos de aleación importantes, como el molibdeno (4.5%), el tungsteno (5.5%) y el vanadio (2.2%), representan colectivamente al menos el 5% de su peso.

El acero para herramientas M2 se utiliza principalmente en herramientas de corte de metal, como brocas helicoidales, machos de roscar, fresas, escariadores, brochas y sierras. También es muy adecuado para aplicaciones de trabajo en frío, como punzones, matrices y herramientas de conformado y prensado. Además, su excelente resistencia a la abrasión lo convierte en una excelente opción para herramientas de moldeo por inyección.

Sí, el acero para herramientas M2 es un buen material para la fabricación de cuchillos gracias a su excelente dureza y resistencia a la abrasión, que le permiten mantener el filo. Sin embargo, no es tan resistente a la corrosión como los aceros inoxidables y no se recomienda para entornos donde la resistencia a la corrosión es crítica.

Sí, el acero para herramientas M2 se utiliza comúnmente en punzones trabajados en frío.

El acero para herramientas de alta velocidad M2 se produce generalmente fundiendo metales en un horno de arco eléctrico junto con los elementos de aleación necesarios. Tras eliminar las impurezas, el metal fundido se cuela en lingotes, que posteriormente se forjan en las formas deseadas para su posterior procesamiento. Posteriormente, el material se recoce y se lamina en caliente para obtener piezas estándar.

Sí, el acero para herramientas M2 se puede forjar, pero es difícil. Tiene una baja forjabilidad y una alta tendencia a agrietarse durante la deformación plástica, incluso después de un tratamiento térmico completo. recocido.

Sí, no es fácil. El acero M2 tiene alta dureza y baja maquinabilidad, típicamente 50-60% de acero al carbono 1% o 39% de acero SAE 1112. Se recomienda utilizar herramientas especializadas, como las que tienen puntas de corte de CBN (nitruro de boro cúbico), debido a la alta dureza del M2.

Sí, el acero para herramientas M2 se puede soldar con métodos de soldadura estándar. Requiere un precalentamiento entre 204 °C y 538 °C (dependiendo de las temperaturas de embutición originales) y un tratamiento térmico posterior a la soldadura.

Los aceros para herramientas M2 y D2 tienen una dureza comparable. Sin embargo, el acero para herramientas D2 tiene un mayor contenido de cromo, lo que proporciona una resistencia a la corrosión ligeramente mejor. Por el contrario, el acero para herramientas M2 ofrece mayor tenacidad y resistencia al desgaste que el D2.

La principal diferencia radica en sus elementos de aleación primarios: el acero para herramientas M2 contiene una cantidad considerable de molibdeno y una cantidad moderada de tungsteno, mientras que el acero para herramientas T1 no contiene molibdeno, pero sí un alto nivel de tungsteno. El M2 ha sustituido en gran medida al T1 en muchas aplicaciones gracias a sus propiedades superiores, como la mayor resistencia a la flexión, tenacidad y termoplasticidad del acero 50%, además de su relativa economía.

Sí, el acero para herramientas M2 se oxida con el tiempo. A pesar de contener cromo y níquel, no está formulado principalmente para resistir la corrosión y presenta una resistencia a la corrosión comparativamente baja en comparación con los aceros inoxidables.

Las principales desventajas del acero para herramientas M2 incluyen su baja capacidad de mecanizado, lo que requiere herramientas y métodos especializados. Además, presenta una resistencia a la corrosión relativamente baja en comparación con los aceros inoxidables. Además, para lograr sus propiedades óptimas se requieren tratamientos térmicos exhaustivos y precisos (recocido, temple y revenido), lo que añade complejidad y coste a su procesamiento. Además, presenta tendencia a agrietarse durante la deformación plástica si no se manipula correctamente.

El acero para herramientas M2 es conocido por ser frágil en su estado templado o si se procesa incorrectamente. Por ejemplo, puede romperse si se golpea con un mazo sin el tratamiento térmico adecuado o si se cae. Sin embargo, cuando se procesa y templa correctamente, el M2 presenta buena tenacidad, lo que significa que es menos propenso a astillarse o agrietarse al exponerse a cargas de impacto y tiende a doblarse en lugar de agrietarse bajo cargas típicas.

Si bien tanto M1 como M2 son aceros para herramientas de alta velocidad para uso general con excelente resistencia y tenacidad, M2 emerge como el más ampliamente utilizado.

Su socio experto en acero para herramientas M2

Aobo Steel trae 20 años de experiencia en forja Ofrecemos acero para herramientas M2 de primera calidad. Reconocido por su excelente resistencia al desgaste, alta dureza y tenacidad, nuestro acero M2 está diseñado para optimizar su eficiencia operativa y la calidad de sus productos.

¿Está listo para hablar sobre sus necesidades específicas de acero M2? Complete el formulario a continuación y nuestros especialistas le brindarán una solución personalizada y un presupuesto competitivo a la brevedad.