Legovaná ocel 4340 | 34CrNiMo6 | 1.6582

AOBO STEEL – Trusted Global Tool Steel Supplier

4340 alloy steel is a prominent type of medium-carbon low-alloy steel and is recognized as an ultrahigh-strength steel. It is often considered the standard against which other ultrahigh-strength steels are compared. The UNS (Unified Numbering System) designation for 4340 alloy steel is G43400. Internationally, it corresponds to standards like SNB23-1-5 or SNB24-1-5 in Japan, and 34CrNiMo6 in Europe. It is also identified by the AMS (Aerospace Material Specification) number 6414.

1. Aplikace

Aircraft and Aerospace: Aircraft parts. Aircraft landing gear. Airframe parts. Connecting rods

Machinery Components: Gears. Pinions. Shafts. Crankshafts and piston rods for engines. Splines

Fasteners: Bolts. Screws. Studs

Structural Components: Pressure vessels. Mountain bicycle frames

2. 4340 Steel Composition1

| uhlík (C) | Chrom (Cr) | nikl (Ni) | molybden (Mo) | mangan (Mn) | křemík (Si) | fosfor (P) | síra (S) |

| 0.38 – 0.43% | 0.70 – 0.90% | 1.65 – 2.00% | 0.20 – 0.30% | 0.60 – 0.80% | 0.20 – 0.35% | ≤ 0,0351 TP3T (max.) | ≤ 0,040% (max.) |

3. 4340 Alloy Steel Properties

3.1 Mechanické vlastnosti

4340 alloy steel exhibits excellent strength, good ductility, and outstanding toughness, as well as resistance to fatigue and creep. Its temperování properties after kalení are roughly equivalent to those of carbon steel. Mechanical properties are greatly influenced by the tempering temperature after oil quenching.

The following table lists the 4340 steel material properties in different oil quenching and tempering conditions.

| Teplota temperování | Pevnost v tahu (MPa / ksi) | Mez kluzu (MPa / ksi) | Tvrdost (HB / HRC) | Rázová houževnatost |

| 205 °C (400 °F) | ~1980 / ~287 | ~1860 / ~270 | ~520HB / ~53HRC | Relativně nižší |

| 425 °C (800 °F) | ~1500 / ~217 | ~1365 / ~198 | ~440HB / ~46HRC | Mírný |

| 540 °C (1000 °F) | ~1150 / ~167 | ~1050 / ~152 | ~360HB/~39HRC | Výrazně vyšší |

| 650 °C (1200 °F) | ~1020 / ~148 | ~860 / ~125 | ~290HB / ~31HRC | Vysoký |

After quenching and tempering, AISI 4340 alloy steel forms a lath martensite microstructure. During rapid cooling, the formation of martensite is accompanied by volume expansion. Depending on the cooling rate, other microstructures, such as bainite, may also form.

3.2 Obrobitelnost

The machinability of steel AISI 4340 is generally rated at 55% for cold-drawn material and 45% for annealed material, relative to B1112 steel (rated at 100%). For optimal machinability, a partly spheroidized microstructure, achieved by normalizing followed by tempering, is recommended.

3.3 Weldability

4340 steel has excellent weldability and can be joined using gas or arc welding processes. However, as an air-hardening steel, it also requires certain protective measures. AISI 4340 steel is more difficult to weld than ordinary carbon steel, and preheating the material and controlling the interpass temperature are necessary during welding. Additionally, annealing or normalizing treatment followed by tempering should be performed as soon as possible after welding.

3.4 Nitriding

AISI 4340 can be readily nitrided, and this process often improves its fatigue life. While 4140 steel, because of its higher chromium content and nickel-free composition, generally exhibits superior nitriding characteristics, 4340 still develops a heavier nitrided case than 8640 steel during the initial 24 hours of nitriding. Typical nitriding temperatures for 4340 steel range from 510 to 550 °C (950 to 1020 °F). Based on our customers’ applications of nitrided 4340 steel for gear manufacturing, the core hardness is typically 38-42 HRC.

3.5 Potential Issues and Processing Precautions

Users of material 4340 by si měl být vědom potenciálních problémů:

- Praskání: Kalení vodou výrazně zvyšuje riziko praskání.

- Vodíkové křehnutí: This can be a concern when the steel is heat-treated to very high tensile strengths (above approximately 1400 MPa / 200 ksi). We suggest baking after processes like pickling or plating.

- Praskání v důsledku koroze v důsledku napětí: Ocel AISI 4340 vykazuje slabou odolnost proti praskání v důsledku koroze v důsledku napětí, zejména při popouštění na vysoké pevnosti v tahu (1500 až 1950 MPa / 220 až 280 ksi).

- Mezikrystalová zlomenina: Citlivost je ovlivněna nečistotami a přítomností vodíku.

- Zkřehnutí za stálého působení: To je u této slitiny známý jev.

Are you seeking a reputable supplier of 4340 alloy steel?

Please fill out the following form to contact us now!

4. Tepelné zpracování

The heat treatment of 4340 steel involves several key processes, each influencing its final microstructure and mechanical properties:

4.1 Kování

The forging temperature is 1065 to 1230°C (1950 to 2250°F). After the forging process, parts can be air-cooled in a dry environment or, preferably, furnace-cooled. The flow stress of 4340 steel can increase by approximately 15% with a 55 °C (100 °F) drop in hot forging temperature.

4.2 Normalizace

Normalizing can improve the microstructure of 4340 steel after uneven cooling at high temperatures. This process is also applicable to alloy steel forgings, rolled products, and castings.

Heat 4340 steel to a temperature 55 to 85°C (100 to 150°F) above its phase transformation temperature (845 to 900°C, or 1550 to 1650°F), at which the original microstructure is completely dissolved into austenite. The material is then cooled to room temperature in air.

4.3 Žíhání

The annealing temperature for 4340 steel is 790-845 °C (1450-1550 °F), with a maximum 4340 steel hardness of 223 HB after annealing.

4.4 Kalení (kalení)

Heat 4340 steel to its austenitic transformation temperature of 800 to 845°C (1475 to 1550°F). We usually select an austenitizing temperature of 845 °C (1550 °F). Soak for approximately 15 minutes per 25 mm (1 inch) of section size, with a minimum hold time of 150 minutes, followed by annealing. For thin-section 4340 steel, annealing is performed by air annealing. For circular sections with a diameter not exceeding 75 mm (3 inches), oil quenching may be used.

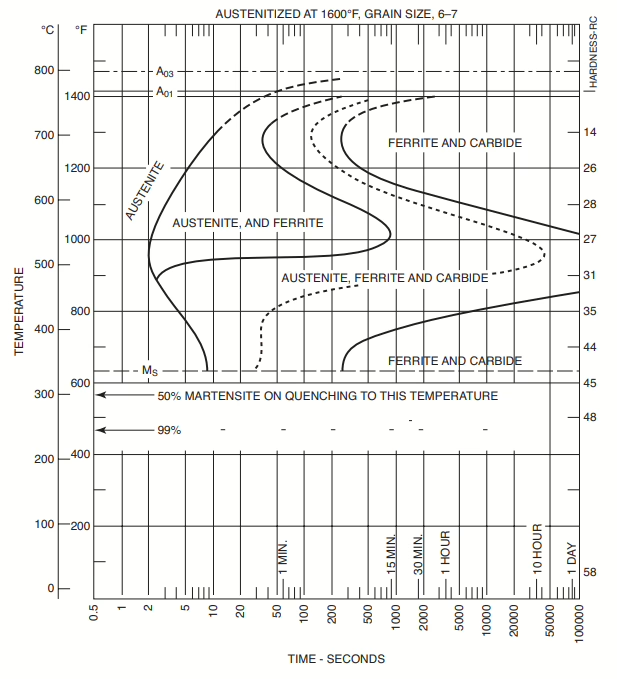

Isothermal transformation diagram for a 4340 steel containing 0.42% C, 0.78% Mn, 1.79% Ni, 0.80% Cr, and 0.33% Mo. [Source: From The Making, Shaping and Treating of Steels, 9th ed., ibid.]

4.5 Temperování

Tempering effectively reduces the brittleness of untempered martensite. Tempering temperatures range from 200 to 650°C (400 to 1200°F) to achieve the required strength levels, and can even reach as high as 705°C (1300°F).

For AISI 4340 steel oil-quenched at 845°C (1550°F), we strongly recommend a tempering temperature of 425°C (800°F), while for water-quenched 4340 steel, we strongly recommend a tempering temperature of 650°C (1200°F).

Variation in hardness with tempering temperature of 4340 steel. All specimens oil quenched from 845 °C (1550 °F) and tempered 2 h at temperature. AQ, as-quenched. [Source: ASM International. (1991). Příručka ASM, svazek 4: Tepelné zpracování (p. 506). ASM International.]

4.6 Uvolnění stresu

This step is designed to reduce residual stress generated by processes such as straightening, forming, or machining. Stress relief for 4340 steel is performed before hardening at a temperature of 650 to 675 °C (1200 to 1250 °F). For hardened 4340 material, the stress relief temperature should not exceed the previous tempering temperature.

4.7 Sféroidizace

The purpose of spheroidizing treatment is to form a spheroidal carbide microstructure in the ferritic matrix, which softens the steel. The maximum temperature for spheroidizing treatment of 4340 steel is 760-775°C (1400-1425°F). A semi-spheroidized structure is obtained by normalizing, followed by tempering at 650°C (1200°F).

5. Ekvivalentní jakosti oceli 4340

| Země/oblast | Ekvivalentní stupeň |

| Amerika | AISI/SAE 4340 |

| Japonsko | JIS SNCM439 |

| Čína | GB 40CrNiMoA |

| EU | EN 34CrNiMo6 (1,6582) |

- Mezinárodní ASM. (1991). Příručka ASM, svazek 4: Tepelné zpracování (p. 496). ASM International. ↩︎

FAQ

AISI/SAE 4340 steel is indeed a very strong and widely recognized material within the category of ultrahigh-strength steels. However, 4340 is not definitively the strongest steel available.

4340 is a type of steel, not aluminum.

Yes, 4340 steel can indeed be hardened, and it is specifically known as a deep-hardening steel

4340 steel is commonly used for highly stressed components in machinery and aircraft, not for knives.

Yes, 4340 steel is a martensitic alloy steel. It is designed and commonly heat-treated to form a martensitic microstructure.

The key distinction between 4140 and 4340 steel is the presence of a significant amount of nickel (Ni) in 4340, which is generally absent in 4140. This nickel addition provides 4340 with superior hardenability and toughness, making it suitable for applications requiring ultra-high strength and improved fracture toughness. While 4140 has good strength and hardenability, it is not a deep-hardening steel. Despite 4340’s overall higher performance, 4140 is noted for better nitriding characteristics due to its nickel-free composition and higher chromium content.

Odemkněte potenciál legované oceli 4340 pro váš projekt

Zažijte vynikající pevnost, houževnatost a všestrannost legované oceli AISI 4340. Ať už potřebujete vysoce výkonné komponenty pro letecký, automobilový průmysl nebo těžké stroje, naše ocel 4340 splňuje i ty nejnáročnější specifikace.

Jste připraveni prodiskutovat vaše požadavky nebo získat cenovou nabídku? Naši odborníci vám pomohou najít perfektní řešení z oceli 4340.

Vyplňte níže uvedený formulář a jeden z našich specialistů vás brzy bude kontaktovat.

Prozkoumejte naše další produkty

D2/1.2379/SKD11

D3/1.2080/SKD1

D6/1,2436/SKD2

A2/1.23663/SKD12

O1/1.2510/SKS3

O2/1,2842

S1/1,2550

S7/1,2355

DC53

H13/1.2344/SKD61

H11/1.2343/SKD6

H21/1,2581/SKD7

L6/1.2714/SKT4

M2/1.3343/SKH51

M35/1.3243/SKH55

M42/1.3247/SKH59

P20/1,2311

P20+Ni/1,2738

420/1.2083/2Cr13

422 z nerezové oceli

Ložisková ocel 52100

Nerezová ocel 440C

4140/42CrMo4/SCM440

4340/34CrNiMo6/1,6582

4130

5140/42Cr4/SCR440

SCM415