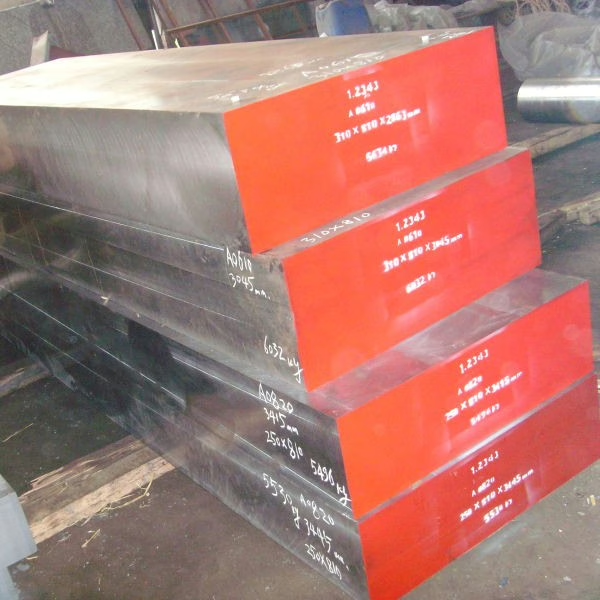

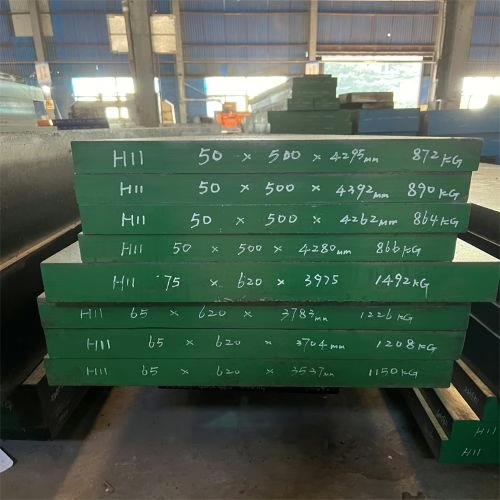

4Cr5MoSiV Hot Work Tool Steel

AOBO STEEL – Trusted Global Tool Steel Supplier

4Cr5MoSiV is a Chinese national standard grade, equivalent to AISI H11 in the United States. Compared with 4Cr5MoSiV1(AISI H13/DIN 1.2343), the vanadium content in the composition of 4Cr5MoSiV is lower. 4Cr5MoSiV1 generally has higher hot strength and hardness, and is more widely used, but 4Cr5MoSiV is still favored for high-speed hammer forging dies due to its excellent thermal fatigue resistance.

1. Chemical Composition(GB / T 1299—2000)

| C | Si | Mn | Cr | Mo | V | P | S |

| 0.33 – 0.43% | 0.80 – 1.20% | 0.20 – 0.50% | 4.75 – 5.50% | 1.10 – 1.60% | 0.30 – 0.60% | ≤0.030% | ≤0.030% |

2. Physical Properties of 4Cr5MoSiV

2.1 Critical Temperatures

| Critical Point | Ac₁ | Ac₃ | Ar₁ | Ar₃ | Ms | Mf |

| Temperature (approx.) / °C | 853 | 912 | 720 | 773 | 310 | 103 |

2.2 Coefficient of Linear Expansion

| Temperature / °C | 20 ~ 100 | 20 ~ 200 | 20 ~ 300 | 20 ~ 400 | 20 ~ 500 | 20 ~ 600 | 20 ~ 700 |

| Coeff. of Linear Expansion α / 10⁻⁶ °C⁻¹ | 10.0 | 10.9 | 11.4 | 12.2 | 12.8 | 13.3 | 13.6 |

2.3 Thermal Conductivity

| Temperature / °C | 100 | 200 | 300 | 400 | 500 | 600 | 700 |

| Thermal Conductivity λ / [W/(m·K)] | 25.9 | 27.6 | 28.4 | 28.0 | 27.6 | 26.7 | 25.9 |

2.4 Modulus of Elasticity

| Temperature / °C | 20 | 100 | 200 | 300 | 400 | 500 |

| Modulus of Elasticity E / MPa | 227,000 | 221,000 | 216,000 | 208,000 | 200,000 | 192,000 |

2.5 Density and Specific Heat Capacity

| Density / (g/cm³) | Specific Heat Capacity cₚ (20°C) / [J/(kg·K)] |

| 7.69 | 459.8 |

3. Hot Forging Process Specification for 4Cr5MoSiV Steel

| Item | Heating Temperature / °C | Initial Forging Temperature / °C | Final Forging Temperature / °C | Cooling Method |

| Steel Ingot | 1140 ~ 1180 | 1100 ~ 1150 | ≥900 | Sand cooling or pit cooling |

| Steel Billet | 1120 ~ 1150 | 1070 ~ 1100 | 850 ~ 900 | Sand cooling or pit cooling |

Please fill out the following contact form to get the latest 4Cr5MoSiV quotation.

4. Heat Treatment of 4Cr5MoSiV

4.1 Preheating

| Preliminary Heat Treatment Plan | Process Parameters |

| Post-forging Annealing | Heating temperature 860 ~ 890°C, hold for 2 ~ 4h; furnace cool to below 500°C then air cool. Hardness after annealing ≤229HBW. |

| Stress Relief Annealing | Heating temperature 730 ~ 760°C, hold for 3 ~ 4h, furnace cool or air cool. |

4.2 Quenching

① Recommended Quenching Process Specification

| Quenching Temperature / °C | Quenching Medium | Quenching Medium Temperature / °C | Subsequent Step | Hardness HRC |

| 1000 ~ 1030 | Oil or Air | 20 ~ 60 | Cool to oil temperature | 53 ~ 55 |

② Relationship between Quenching Temperature and Hardness

| Quenching Temperature / °C | 950 | 975 | 1000 | 1025 | 1050 | 1075 | 1100 |

| Hardness HRC | 51 | 53 | 54.5 | 56 | 58 | 58.5 | 57.5 |

4.3 Tempering

① Recommended Tempering Process Specification

| Purpose of Tempering | Temperature / °C | Equipment | Cooling | Number of Tempers | Hardness HRC |

|---|---|---|---|---|---|

| Eliminate stress and reduce hardness | 530 ~ 580 | Molten salt bath furnace or air furnace | Air cool | 2 | 47 ~ 49 |

Note: The second tempering temperature is usually 20 ~ 30°C lower than the first.

② Mechanical Properties after Tempering at Different Temperatures

| Tempering Temperature / °C | 500 | 550 | 600 | 650 |

|---|---|---|---|---|

| Hardness HRC | 57 | 54.5 | 46.5 | 37 |

| aᴋ / (J/cm²) | 20 | 45 | 60 | 66 |

Note: 1000°C air cool, 580°C temper.

4.4 Recommended Surface Strengthening Treatment Process Specification

| Process | Temperature / °C | Time / h | Medium | Layer Thickness / mm | Surface Hardness HV |

|---|---|---|---|---|---|

| Nitriding | 560 | 2 | KNO₃ 50% + NaNO₃ 50% (Mass Fraction) | 0.04 | 640 ~ 690 |

| Nitriding | 580 | 8 | Natural Gas + Ammonia | 0.25 ~ 0.30 | 830 ~ 860 |

| Nitriding | 540 | 12 ~ 20 | Ammonia decomposition rate 30% ~ 60% | 0.15 ~ 0.20 | 550 ~ 750 |

5. Mechanical Properties

4Cr5MoSiV (H11) steel is an air-cooling hardening type hot-work tool steel. It has good toughness, and after heat treatment strengthening, its strength can reach over 2070 MPa. Because it can be hardened in air, quenching deformation and residual stress are small, and the tendency for surface oxidation is also small. It can produce a secondary hardening phenomenon and can achieve optimal performance when tempered above 510°C. After high-temperature tempering, most of the internal stress can be eliminated. It has good thermal stability and can resist the erosion of molten aluminum alloy. Below 650°C, it has high ductility, impact toughness, oxidation resistance, thermal fatigue resistance, as well as high creep strength and tensile strength.

5.1 High-Temperature Mechanical Properties

| Test Temperature / °C | Rₘ / MPa | Rₑₗ / MPa | A (%) | Z (%) |

| 300 | 1504 | 1311 | 12.0 | 39.1 |

| 600 | 895 | 794 | 21.9 | 72.9 |

| 650 | 471 | 402 | 33.1 | 85.5 |

| 700 | 226 | 179 | 55.0 | 94.5 |

5.2 High-Temperature Hardness

| Test Temperature / °C | 300 | 450 | 600 | 650 | 700 | 750 |

|---|---|---|---|---|---|---|

| Hardness HV | 491.5 | 448.5 | 384.0 | 302.5 | 227.5 | 178.5 |

Note: Original hardness of the specimen 49~50HRC.

5.3 High-Temperature Impact Toughness

| Test Temperature / °C | 300 | 600 | 650 | 700 |

|---|---|---|---|---|

| Impact Absorption Energy K / J | 28.8 | 31.0 | 36.5 | 70.0 |

5.4 Thermal Fatigue Performance

| Grade | |

|---|---|

| 20 ~ 650°C repeated 1000 times | 8.2 |

| 20 ~ 750°C repeated 1000 times | 14.6 |

5.5 Thermal Wear Resistance

4Cr5MoSiV Steel Thermal Wear Resistance (I)

| Rotations/times | 300 | 600 | 900 | 1200 | 1500 | 2500 |

|---|---|---|---|---|---|---|

| Weight Loss / mg | 0.67 | 0.80 | 1.4 | 1.63 | 1.97 | 2.62 |

Note: Test temperature 800 ~ 850°C, pressure 784 ~ 882N, specimen hardness 49 ~ 50HRC.

Table 5-89 4Cr5MoSiV Steel Thermal Wear Resistance (II)

| Rotations/times | 100 | 200 | 300 | 400 | 500 | 600 | 700 | 1000 |

|---|---|---|---|---|---|---|---|---|

| Weight Loss / mg | 0.77 | 1.67 | 2.50 | 3.47 | 4.33 | 4.90 | 5.60 | 7.40 |

Note: Test temperature 910 ~ 950°C, pressure 1784 ~ 1813N, specimen hardness 49 ~ 50HRC.

5.6 Tempering Resistance

| Temperature / °C | 500 (Secondary Hardening Peak Temperature) | 560 | 615 | 600 | 653 |

|---|---|---|---|---|---|

| Hardness HRC | 55.0 (Highest Secondary Hardening Hardness) | 49.0 | 42.0 | 36.0 | 35.0 |

Note: Specimen quenched in oil at 1020°C, hardness 59~60HRC.

5.7 Thermal Corrosion Resistance

| Test Temperature and Time | 620°C × 4h | 680°C × 4h |

|---|---|---|

| Weight Loss / (g/dm²) | 4.4188 | 16.4 |

5.8) Fatigue Limit

| Test Temperature / °C | Room Temp | 300 | 400 | 450 | 500 |

|---|---|---|---|---|---|

| σ-1 / MPa | 880 | 680 | 640 | 630 | 610 |

| σ-1k / MPa | 570 | 440 | 430 | — | 420 |

5.9 Thermal Stability of 4Cr5MoSiV Steel at 620°C

| Holding Time / h | 2 | 4 | 6 | 8 | 11.5 | 14.5 | 17.5 | 21 |

|---|---|---|---|---|---|---|---|---|

| Hardness HRC | 39.4 | 38.4 | 36.9 | 35.1 | 34.4 | 33.2 | 32.6 | 32.3 |

Note: Original hardness of the specimen was 49.9 HRC.

6. Applications

4Cr5MoSiV (H11) steel is commonly used for manufacturing die-casting molds for aluminum castings, hot extrusion dies, tools and core rods for piercing, press forging dies, plastic molds, etc. Additionally, due to its good medium-temperature strength, it is also used for manufacturing structural components for aircraft, rockets, and parts for steam turbines and gas turbines.

Get a Competitive Quote for 4Cr5MoSiV Tool Steel

With over 20 years of forging expertise, Aobo Steel is your trusted partner for high-performance 4Cr5MoSiV tool steel. We provide not just materials, but solutions. Leverage our deep industry knowledge and reliable supply chain for your project’s success.

✉ Contact us by filling out the form below.