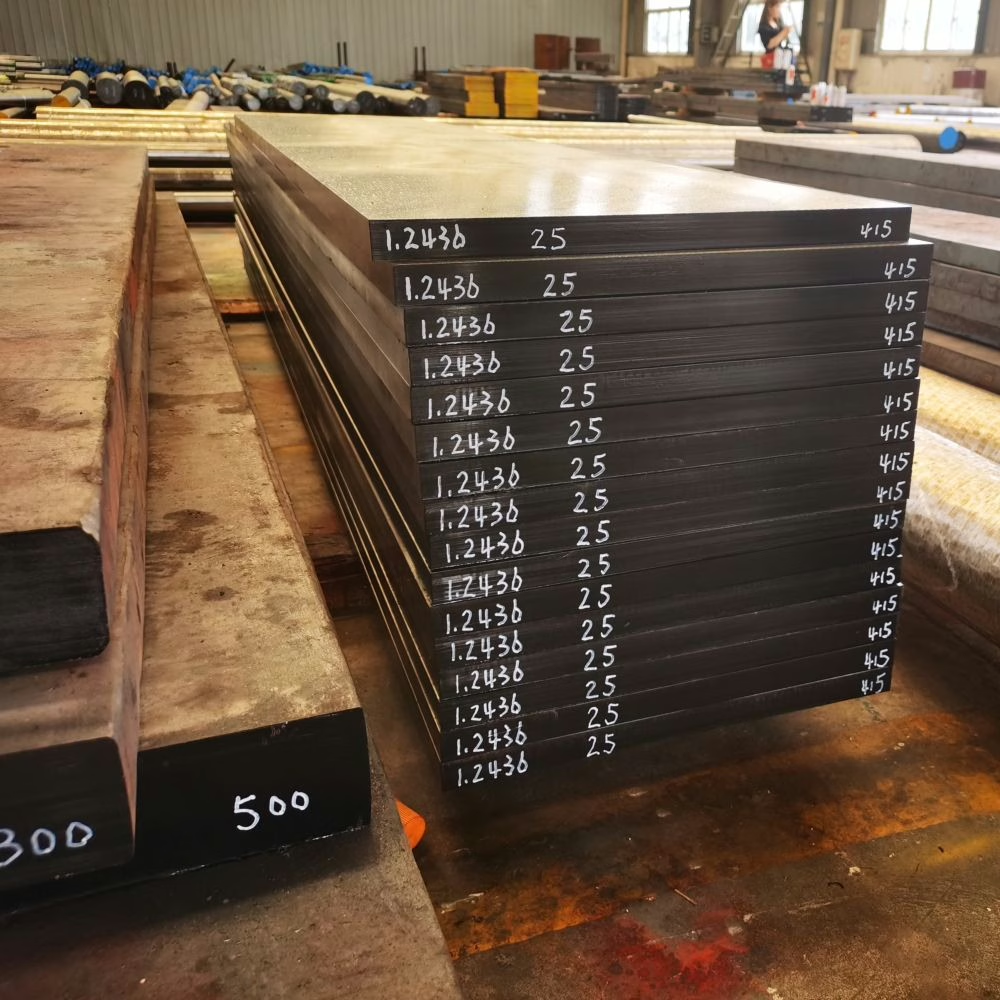

Satılık Aobo Steel 1.2436 Takım Çeliği

Aobo Steel projeniz için 1.2436 takım çeliği tedarik ediyor

Güvenilir bir 1.2436 takım çeliği tedarikçisi arayan işletmeler için Aobo Steel kapsamlı bir çözüm yelpazesi sunar. Takım çeliğinde yüksek aşınma direnci arıyorsanız, 1.2436 çelik mükemmel bir seçimdir. Özellikle, 1.2436 çelik aşırı dayanıklılık için tasarlanmış krom açısından zengin, soğuk iş takım çeliğidir. Aslında, bu yüksek karbonlu çelik tipik düşük alaşımlı çeliğin 3-4 katı aşınma direnci sağlar. Dahası, mükemmel sertlik, tokluk ve boyutsal kararlılık sunar ve bu da onu zorlu takım uygulamaları için ideal hale getirir.

Uygulamalar

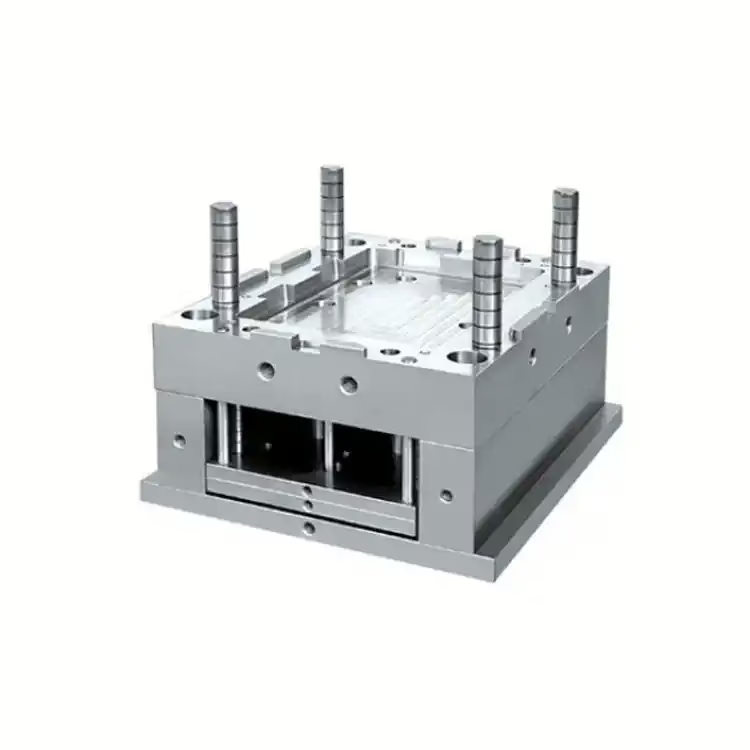

1.2436 takım çeliği, özellikle büyük kesitli ve karmaşık şekilli soğuk iş kalıpları yapmak için yaygın olarak kullanılır. Bu kalıplar genellikle önemli darbe kuvvetlerine maruz kalır ve yüksek aşınma direnci gerektirir. Uygulamalar arasında silikon çelik delme kalıpları, diş açma kalıpları ve çekme kalıpları bulunur.

- 1.2436, öncelikle orta yük damgalama kalıpları için uygundur. Paslanmaz çelik, bakır, silikon ve alüminyum delmede mükemmeldir.

- 1.2436, orta yük altında paslanmaz çelik ve silikon çelik sac damgalama kalıpları için yaygın olarak kullanılır. Ayrıca derin kap parçası damgalama kalıpları için de etkilidir.

Soğuk Şekillendirme Aletleri: Aobo Steel – 1.2436 Çelik Tedarikçisi

Sağlam soğuk şekillendirme aletleri için 1.2436 çelik tedarikçiniz Aobo Steel'e güvenin. 1.2436 çelik, zorlu şekillendirme işlemleri için yüksek basınç dayanımı sağlar. Güvenilir şekillendirme aletleri için 1.2436 takım çeliği tedarikçisi Aobo Steel'i seçin.

1.2436 çelik genel bakış

Kimyasal bileşim

| C (Karbon) | Si (Silikon) | Mn (Manganez) | P (Fosfor) | S (Kükürt) | Cr (Krom) | W (Tungsten) |

| 2.00% – 2.25% | 0.10% – 0.40% | 0,15% – 0,45% | ≤0.030% | ≤0.030% | 11.0% – 12.0% | 0,60% – 0,80% |

Isıl işlem

1. Yumuşak Tavlama

Amaç: Sertliği azaltmak ve işlenebilirliği iyileştirmek.

Isıtma sıcaklığı: 780-820°C

Tutma süresi: 2-4 saat (iş parçasının boyutuna bağlı olarak)

Soğutma yöntemi: Fırında 500°C'ye kadar soğutma, ardından havada soğutma

Tavlama sonrası sertlik: ≤ 229 HB

2. Söndürme

Amaç: Yüksek sertlik ve aşınma direnci elde etmek.

Ön ısıtma sıcaklığı: 600-650°C (termal stresi azaltmak için)

Austenitleme sıcaklığı: 950-980°C

Tutma süresi: 25 mm başına 30 dakika (iş parçası kalınlığı)

Soğutma ortamı: Yağ veya hava

Söndürme sonrası sertlik: 62-64 HRC

3. Tavlama

Amaç: Söndürme stresini azaltmak ve tokluğu artırmak.

Tavlama sıcaklığı: Hedef sertliğe göre seçilir (aşağıdaki tabloya bakın)

Tutma süresi: 25 mm başına 2 saat (iş parçası kalınlığı)

Soğutma yöntemi: Hava soğutma

| Temperleme Sıcaklığı (°C) | Sertlik (HRC) | Başvuru |

|---|---|---|

| 150-200 | 60-62 | Yüksek aşınma direnci |

| 200-300 | 58-60 | Dengeli aşınma direnci ve tokluk |

| 300-400 | 55-58 | Yüksek tokluk |

Derin Çekme Aletleri: Aobo Steel – 1.2436 Tedarikçi

Zorlu derin çekme takımları için 1.2436 çeliğinin güvenilir tedarikçisi olan Aobo Steel'i düşünün. Bu çelik, derin çekme uygulamaları için sağlam ve aşınmaya dayanıklıdır; dayanıklı takımlar için Aobo Steel ile ortak olun.