Aço-liga 4340 | 34CrNiMo6 | 1,6582

AOBO STEEL – Fornecedor global confiável de aço para ferramentas

O aço-liga 4340 é um tipo proeminente de aço de médio carbono e baixa liga, reconhecido como um aço de ultra-alta resistência. É frequentemente considerado o padrão com o qual outros aços de ultra-alta resistência são comparados. A designação UNS (Sistema Unificado de Numeração) para o aço-liga 4340 é G43400. Internacionalmente, corresponde a normas como SNB23-1-5 ou SNB24-1-5 no Japão e 34CrNiMo6 na Europa. Também é identificado pelo número 6414 da AMS (Especificação de Material Aeroespacial).

1. Aplicações

Aeronaves e Aeroespacial: Peças de aeronaves. Trem de pouso de aeronaves. Peças de fuselagem. Bielas.

Componentes de Máquinas: Engrenagens. Pinhões. Eixos. Virabrequins e bielas para motores. Estrias.

Fixadores: Parafusos. Pinos.

Componentes estruturais: Vasos de pressão. Quadros de bicicletas de montanha.

2. Composição do aço 43401

| Carbono (C) | Cromo (Cr) | Níquel (Ni) | Molibdênio (Mo) | Manganês (Mn) | Silício (Si) | Fósforo (P) | Enxofre (S) |

| 0,38 – 0,43% | 0,70 – 0,90% | 1,65 – 2,00% | 0,20 – 0,30% | 0,60 – 0,80% | 0,20 – 0,35% | ≤ 0,035% (máx.) | ≤ 0,040% (máx.) |

3. Propriedades do aço de liga 4340

3.1 Propriedades Mecânicas

O aço-liga 4340 apresenta excelente resistência, boa ductilidade e tenacidade excepcional, além de resistência à fadiga e à fluência. Suas propriedades de revenido após têmpera são aproximadamente equivalentes às do aço carbono. As propriedades mecânicas são fortemente influenciadas pela temperatura de revenido após têmpera em óleo.

A tabela a seguir lista as propriedades do aço 4340 em diferentes condições de têmpera e revenido em óleo.

| Temperatura de têmpera | Resistência à tração (MPa / ksi) | Limite de escoamento (MPa / ksi) | Dureza (HB / HRC) | Resistência ao Impacto |

| 205°C (400°F) | ~1980 / ~287 | ~1860 / ~270 | ~520HB / ~53HRC | Relativamente mais baixo |

| 425°C (800°F) | ~1500 / ~217 | ~1365 / ~198 | ~440HB / ~46HRC | Moderado |

| 540°C (1000°F) | ~1150 / ~167 | ~1050 / ~152 | ~360HB/~39HRC | Notavelmente mais alto |

| 650°C (1200°F) | ~1020 / ~148 | ~860 / ~125 | ~290HB / ~31HRC | Alto |

Após a têmpera e o revenimento, o aço-liga AISI 4340 forma uma microestrutura de martensita em forma de ripa. Durante o resfriamento rápido, a formação de martensita é acompanhada por expansão de volume. Dependendo da taxa de resfriamento, outras microestruturas, como a bainita, também podem se formar.

3.2 Usinabilidade

A usinabilidade do aço AISI 4340 é geralmente classificada como 55% para material trefilado a frio e 45% para material recozido, em comparação ao aço B1112 (classificado como 100%). Para uma usinabilidade ideal, recomenda-se uma microestrutura parcialmente esferoidizada, obtida por normalização seguida de revenimento.

3.3 Soldabilidade

O aço 4340 possui excelente soldabilidade e pode ser unido por meio de processos de soldagem a gás ou a arco. No entanto, como é um aço endurecível ao ar, também requer certas medidas de proteção. O aço AISI 4340 é mais difícil de soldar do que o aço carbono comum, sendo necessário pré-aquecer o material e controlar a temperatura entre passes durante a soldagem. Além disso, o tratamento de recozimento ou normalização seguido de revenimento deve ser realizado o mais breve possível após a soldagem.

3.4 Nitretação

O aço AISI 4340 pode ser facilmente nitretado, e esse processo geralmente melhora sua vida útil à fadiga. Embora o aço 4140, devido ao seu maior teor de cromo e composição isenta de níquel, geralmente apresente características de nitretação superiores, o 4340 ainda desenvolve uma camada nitretada mais espessa do que o aço 8640 durante as primeiras 24 horas de nitretação. As temperaturas típicas de nitretação para o aço 4340 variam de 510 °C a 550 °C (950 °F a 1020 °F). Com base nas aplicações de nossos clientes de aço 4340 nitretado para fabricação de engrenagens, a dureza do núcleo normalmente varia de 38 a 42 HRC.

3.5 Problemas Potenciais e Precauções de Processamento

Os utilizadores do material 4340 devem estar cientes dos potenciais desafios:

- Rachaduras: O resfriamento com água aumenta significativamente o risco de rachaduras.

- Fragilização por hidrogênio: Isso pode ser um problema quando o aço é tratado termicamente para resistências à tração muito altas (acima de aproximadamente 1400 MPa / 200 ksi). Sugerimos o cozimento após processos como decapagem ou galvanoplastia.

- Trincas por corrosão sob tensão: Aço AISI 4340 Apresenta baixa resistência à fissuração por corrosão sob tensão, particularmente quando temperado para altas resistências à tração (1.500 a 1.950 MPa / 220 a 280 ksi).

- Fratura Intergranular: A suscetibilidade é influenciada por impurezas e pela presença de hidrogênio.

- Fragilização por têmpera: Este é um fenômeno conhecido para esta liga.

Você está procurando um fornecedor confiável de aço-liga 4340? Preencha o formulário abaixo para entrar em contato conosco agora mesmo!

4. Tratamento térmico

O tratamento térmico do aço 4340 envolve vários processos principais, cada um influenciando sua microestrutura final e propriedades mecânicas:

4.1 Forjamento

A temperatura de forjamento é 1065 a 1230°C (1950 a 2250°F)Após o processo de forjamento, as peças podem ser resfriadas ao ar em ambiente seco ou, preferencialmente, resfriadas em forno. A tensão de escoamento do aço 4340 pode aumentar em aproximadamente 15% com uma queda de 55 °C (100 °F) na temperatura de forjamento a quente.

4.2 Normalização

A normalização pode melhorar a microestrutura do aço 4340 após resfriamento irregular em altas temperaturas. Este processo também é aplicável a peças forjadas, produtos laminados e fundidos de aço-liga.

Aqueça o aço 4340 a uma temperatura de 55 a 85 °C (100 a 150 °F) acima de sua temperatura de transformação de fase (845 a 900 °C ou 1550 a 1650 °F), na qual a microestrutura original se dissolve completamente em austenita. Em seguida, o material é resfriado à temperatura ambiente ao ar.

4.3 Recozimento

A temperatura de recozimento do aço 4340 é de 790-845 °C (1450-1550 °F), com uma dureza máxima do aço 4340 de 223 HB após o recozimento.

4.4 Resfriamento

Aqueça o aço 4340 até sua temperatura de transformação austenítica, que varia de 800 a 845 °C (1475 a 1550 °F). Normalmente, selecionamos uma temperatura de austenitização de 845 °C (1550 °F). Mantenha nessa temperatura por aproximadamente 15 minutos a cada 25 mm (1 polegada) de seção transversal, com um tempo mínimo de espera de 150 minutos, seguido de recozimento. Para seções finas de aço 4340, o recozimento é realizado ao ar. Para seções circulares com diâmetro não superior a 75 mm (3 polegadas), pode-se utilizar têmpera em óleo.

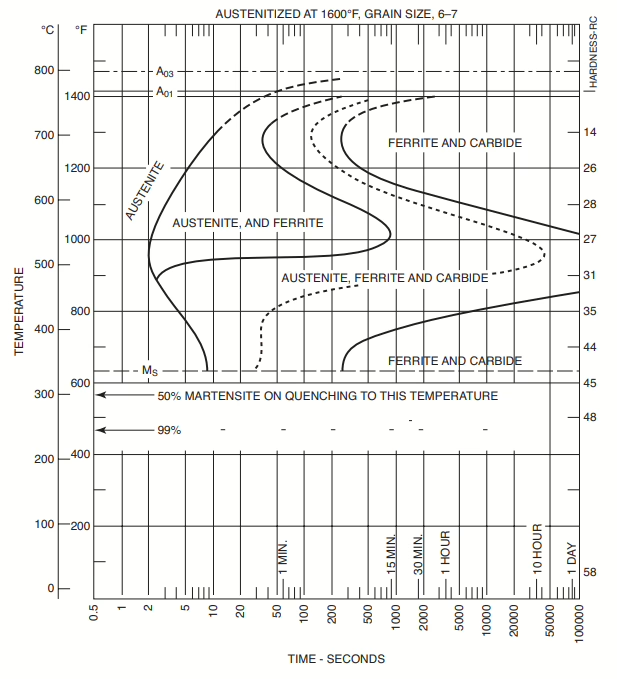

Diagrama de transformação isotérmica para um aço 4340 contendo 0,42% C, 0,78% Mn, 1,79% Ni, 0,80% Cr e 0,33% Mo. [Fonte: De The Making, Shaping and Treating of Steels, 9ª ed., ibid.]

4.5 Têmpera

O revenimento reduz eficazmente a fragilidade da martensita não revenida. As temperaturas de revenimento variam de 200 a 650 °C (400 a 1200 °F) para atingir os níveis de resistência necessários, podendo chegar até 705 °C (1300 °F).

Para o aço AISI 4340 temperado em óleo a 845 °C (1550 °F), recomendamos enfaticamente uma temperatura de revenido de 425 °C (800 °F). Para o aço 4340 temperado em água, recomendamos uma temperatura de revenido de 650 °C (1200 °F).

Variação da dureza em função da temperatura de revenido do aço 4340. Todas as amostras foram temperadas em óleo a partir de 845 °C (1550 °F) e revenidas por 2 h nessa temperatura. AQ, como temperado.2.

4.6 Alívio do Estresse

Esta etapa visa reduzir a tensão residual gerada por processos como endireitamento, conformação ou usinagem. O alívio de tensões para o aço 4340 é realizado antes do endurecimento a uma temperatura de 650 a 675 °C (1200 a 1250 °F). Para o material 4340 endurecido, a temperatura de alívio de tensões não deve exceder a temperatura de revenimento anterior.

4.7 Esferoidização

O objetivo do tratamento de esferoidização é formar uma microestrutura de carboneto esferoidal na matriz ferrítica, que amolece o aço. A temperatura máxima para o tratamento de esferoidização do aço 4340 é de 760-775 °C (1400-1425 °F). Uma estrutura semiesferoidizada é obtida pela normalização, seguida de revenimento a 650 °C (1200 °F).

5. 4340 Graus equivalentes de aço

| País/Região | Grau equivalente |

| América | AISI/SAE 4340 |

| Japão | JIS SNCM439 |

| China | GB 40CrNiMoA |

| UE | EN 34CrNiMo6 (1,6582) |

- ASM Internacional. (1991). Manual ASM, Volume 4: Tratamento Térmico (p. 496). ASM Internacional. ↩︎

- ASM Internacional. (1991). Manual ASM, Volume 4: Tratamento Térmico (p. 506). ASM Internacional. ↩︎

Perguntas frequentes

O aço AISI/SAE 4340 é de fato um material muito resistente e amplamente reconhecido na categoria de aços de ultra-alta resistência. No entanto, o 4340 não é definitivamente o aço mais resistente disponível.

4340 é um tipo de aço, não alumínio.

Sim, o aço 4340 pode de fato ser endurecido e é especificamente conhecido como aço de endurecimento profundo

O aço 4340 é comumente usado em componentes altamente tensionados em máquinas e aeronaves, não em facas.

Sim, o aço 4340 é um aço de liga martensítico. Ele é projetado e comumente tratado termicamente para formar uma microestrutura martensítica.

A principal diferença entre os aços 4140 e 4340 é a presença de uma quantidade significativa de níquel (Ni) no 4340, geralmente ausente no 4140. Essa adição de níquel confere ao 4340 temperabilidade e tenacidade superiores, tornando-o adequado para aplicações que exigem ultra-alta resistência e melhor tenacidade à fratura. Embora o 4140 tenha boa resistência e temperabilidade, não é um aço de endurecimento profundo. Apesar do desempenho geral superior do 4340, o 4140 se destaca por suas melhores características de nitretação devido à sua composição isenta de níquel e ao maior teor de cromo.

Libere o potencial do aço de liga 4340 para seu projeto

Experimente a resistência, tenacidade e versatilidade superiores do aço-liga AISI 4340. Seja para componentes de alto desempenho para a indústria aeroespacial, automotiva ou de máquinas pesadas, nosso aço 4340 atende às especificações mais exigentes.

Pronto para discutir suas necessidades ou solicitar um orçamento? Nossos especialistas estão à disposição para ajudá-lo a encontrar a solução perfeita em aço 4340.

Preencha o formulário abaixo e um de nossos especialistas entrará em contato com você em breve.