Stal narzędziowa H11 to hartowana metodą chłodzenia powietrzem stal narzędziowa do pracy na gorącoStal ta charakteryzuje się doskonałą wytrzymałością, wytrzymałością termiczną, odpornością na zmęczenie i zużycie w średnich temperaturach. Ponadto zachowuje pewną wytrzymałość w stanie zahartowanym i wykazuje wysoką odporność na zmęczenie cieplne. Po hartowaniu w powietrzu w niższych temperaturach austenityzacji wykazuje minimalne odkształcenia po obróbce cieplnej i niską tendencję do tworzenia się warstwy tlenkowej. Stal narzędziowa H11 skutecznie chroni przed korozją ciekłego aluminium, co czyni ją popularnym wyborem do produkcji aluminiowych form odlewniczych, narzędzi do wytłaczania na gorąco, form do tłoczenia i kucia oraz form do tworzyw sztucznych.

Oznaczenie tej stali w amerykańskim systemie ASTM A681 to H11. Podobnie, inne normy krajowe stosują porównywalne oznaczenia, takie jak ISO X37CrMoV5-1, Japonia/JIS SKD6, USA/UNS T20811, Niemcy/DIN X38CrMoV5-1, Niemcy/W-Nr. 1.2343, Czechy (CSN) 19552 i Chiny/GB. 4Cr5MoSiV.

1. Zastosowania

- Odlewy ciśnieniowe

- Matryce kuźnicze

- Narzędzia do wytłaczania

- Ostrza do nożyc na gorąco:

- Komponenty lotnicze

2. Skład chemiczny1

| C | Mn | Si | Kr | Mo | V |

| 0,33 – 0,43% | 0,20 – 0,60% | 0,80 – 1,25% | 4,75 – 5,50% | 1.10 – 1.60% | 0,30 – 0,60% |

Gatunki równoważne stali narzędziowej H11 i ich składy

| Oceny | C | Si | Mn | P | S | Kr | Mo | V |

| DIN 1.2343 | 0.33 – 0.43% | 0.80 – 1.25% | 0.20 – 0.60% | ≤ 0,030% | ≤ 0,030% | 4.75 – 5.50% | 1.10 – 1.60% | 0.30 – 0.60% |

| JIS SKD6 | 0.32 – 0.42% | 0.80 – 1.20% | 0.20 – 0.50% | ≤ 0,030% | ≤ 0,030% | 4.50 – 5.50% | 1.00 – 1.50% | 0.30 – 0.60% |

| GB 4Cr5MoSiV | 0.33 – 0.43% | 0.80 – 1.20% | 0.20 – 0.50% | ≤ 0,030% | ≤ 0,030% | 4.75 – 5.50% | 1.10 – 1.60% | 0.30 – 0.60% |

3. Właściwości2

Stal narzędziowa H11 charakteryzuje się wyjątkowym połączeniem osiągalnej twardości, twardości w wysokiej temperaturze, wytrzymałości i odporności na zużycie.

- Wytrzymałość:Można go poddać obróbce cieplnej, aby uzyskać wytrzymałość 0,2% znacznie wyższą niż 1380 MPa (200 ksi) i wytrzymałości na rozciąganie przekraczającej 2070 MPa (300 ksi).

- Twardość: Normalne twardości robocze zwykle mieszczą się w zakresie od 40 do 55 HRC. W przypadku zastosowań takich jak odlewanie ciśnieniowe aluminium preferowana jest twardość 47 HRC. W odlewaniu ciśnieniowym matryce H11 mogą być hartowane do 42–52 HRC, wkładki i rdzenie do 46–52 HRC, tłoki do 46–50 HRC, suwaki do 46–52 HRC, tuleje wtryskowe do 44–48 HRC, a dysze do 32–42 HRC. W przypadku stempli i matryc do kucia na gorąco twardość zwykle mieści się w zakresie od 44 do 48 HRC. Walce walcowni na gorąco (do krótkich serii i niskich temperatur) wykorzystują H11 o twardości 40–48 HRC. Matryce do kucia na gorąco mają zwykle twardość 48–52 HRC.

- Twardość na gorąco/twardość czerwona: Dobra odporność na odpuszczanie, utrzymująca wysoką twardość i wytrzymałość w podwyższonych temperaturach. Odporna na zmiękczenie podczas ciągłej ekspozycji na temperatury do 540 °C (1000 °F). Podczas gdy jej twardość na gorąco jest niższa niż niektórych innych stali do obróbki na gorąco, takich jak H19 lub H21, nadal zachowuje twardość lepiej niż inne stale średniostopowe w wyższych temperaturach. Twardość na gorąco/twardość czerwona to bardzo ważna właściwość stali narzędziowych do obróbki na gorąco.

- Wytrzymałość i ciągliwość: Dobra ciągliwość i wytrzymałość na uderzenia. Posiada lepszą odporność na kruche pękanie w porównaniu do stali o wyższej zawartości stopu, takich jak H14, H19 i H21. Procesy topienia elektrożużlowego (ESR) lub próżniowego łukowego (VAR) mogą znacznie poprawić ciągliwość i wytrzymałość.

- Odporność na zmęczenie: Materiał ten może zapewnić wysoki poziom odporności na zmęczenie i stabilność termiczną w zakresie temperatur od 75 do 540°C (od 167 do 1000°F). W porównaniu ze stalą 4340, która przeszła taką samą obróbkę cieplną o wysokiej intensywności, H11 ma lepszą wytrzymałość zmęczeniową.

- Odporność na zużycie:Jego odporność na zużycie jest niższa niż w przypadku H13.

- Spawalność: Jest on łatwy do spawania, nawet w przypadku grubych przekrojów.

- Obróbka skrawaniem: Dobra obrabialność, ocena na poziomie około 70% dla standardowej stali węglowej 1%.

- Właściwości termiczne:Ma stosunkowo niski współczynnik rozszerzalności cieplnej i przewodność cieplną wynoszącą 26 W/m·K.

- Odporność na korozję:Ponadprzeciętna odporność na utlenianie i korozję.

- Sprawdzenie odporności na ciepło: Dobra odporność na zmęczenie cieplne i pęknięcia cieplne.

Interesuje Cię stal narzędziowa H11? Wypełnij poniższy formularz, aby skontaktować się z nami już teraz!

4. H11 Obróbka cieplna stali narzędziowej

Dokładny Obróbka cieplna stali narzędziowej H11 jest kluczowy dla uzyskania optymalnej wydajności jako stal do obróbki na gorąco 5% z chromem i stal o ultra wysokiej wytrzymałości, podobna do H11 Modified i H13. Proces ten dostraja mikrostrukturę do wymagających narzędzi fabrycznych.

4.1 Kucie

Stal ta jest łatwa w kuciu, a odpowiedni zakres temperatur kucia wynosi od 1120 do 1150°C (2050 do 2100°F). Zalecamy wstępne podgrzanie wlewka do temperatury 790–815°C (1450–1500°F), a następnie równomierne podgrzanie do temperatury kucia. Temperatura kucia NIE może być niższa niż 925°C (1700°F). Jeśli temperatura spadnie w pobliże tego poziomu, należy go ponownie podgrzać przed kontynuowaniem procesu kucia.

4.2 Austenityzowanie (hartowanie)

Austenityzowanie, czyli podstawowy etap hartowania, polega na nagrzaniu w celu zmiany struktury austenit. Pozwala to na równomierną konwersję i rozpuszczenie pierwiastków stopowych i węglików.

- Podgrzewanie: Zaleca się podgrzanie materiału H11 do temperatury 760–815 °C (1400–1500 °F) przed austenityzacją w celu zminimalizowania szoku termicznego i pęknięć, szczególnie w przypadku tego materiału wysokostopowego.

- Temperatury austenityzacji i czasy wygrzewania: Temperatura austenityzowania wynosi 995–1025 °C (1825–1875 °F). Czas namaczania wynosi 20 minut + 5 minut na każde 25 mm (1 cal) grubości.

Utrzymywanie temperatury austenityzacji zapewnia równomierną przemianę i rozpuszczenie.

4.3 Hartowanie

After austenitizing, H11 steel is rapidly quenched to form hard martenzyt. H11 is an air-hardening steel, providing uniform hardening through large sections with minimal residual stress and dimensional change. Air cooling is the standard and preferred method for H11 tool steel. While air cooling is standard, oil quenching from 995 °C (1825 °F) is a possible alternative. H11 and other hot work tool steels must nigdy nie gaś wodyponieważ może to prowadzić do pęknięć.

4.4 Hartowanie

Po hartowaniu, odpuszczanie stali narzędziowej H11 poprzez ponowne podgrzanie do niższej temperatury ma kluczowe znaczenie dla poprawy wytrzymałości, odprężenia i stabilizacji właściwości. Stal H11 jest stalą hartowaną wtórnie. Osiąga najlepsze parametry po odpuszczeniu w temperaturze powyżej 510°C (950°F). Zalecamy wielokrotne odpuszczanie, aby uzyskać optymalną wytrzymałość i wydłużyć żywotność narzędzia. Pomiędzy każdym cyklem odpuszczania należy pozwolić elementom ostygnąć do temperatury pokojowej, aby zminimalizować ilość austenitu resztkowego.

Tabela twardości i temperatury odpuszczania dla stali H11

| Temperatura hartowania | Rockwell C |

| Jak ugasić | 56 |

| 700°F/370°C | 54 |

| 800°F/425°C | 55 |

| 900°F/480°C | 57 |

| 1000°F/540°C | 56 |

| 1100°F/595°C | 46 |

| 1200°F/650°C | 36 |

4.5 Wyżarzanie

Ten wyżarzanie temperature ranges from 845 to 900°C (1550-1650°F). The cooling rate is 22-40°C/h (40-75°F/h). The hardness after annealing is 192-229 HB.

4.6 Inne ważne kwestie dotyczące obróbki cieplnej H11

- Normalizowanie: Ten proces jest ogólnie niezalecane do stali narzędziowych H11 lub H13 ze względu na wysokie ryzyko pękania, szczególnie w przypadku odwęglenia powierzchni.

- Ulgę w stresie: Po obróbce H11, takiej jak szlifowanie, spawanie lub obróbka elektroerozyjna (EDM), zdecydowanie zalecamy poddanie go obróbce odprężającej w temperaturze 650°C. Obróbkę tę należy przeprowadzić w temperaturze o 14–28°C (25–50°F) niższej niż poprzednia temperatura odpuszczania. Po odprężeniu należy powoli schładzać z maksymalną szybkością 300°C/h, aby zapobiec powstawaniu nowych naprężeń.

- Leczenie kriogeniczne: Obróbka w temperaturze poniżej zera (np. -73°C / -100°F) może zmniejszyć ilość austenitu szczątkowego; jednak wysokie temperatury odpuszczania H11 zwykle sprawiają, że nie jest konieczne osiągnięcie maksymalnej reakcji utwardzania wtórnego.

- Ochrona powierzchni: Ochrona powierzchni przed utlenianiem i odwęglaniem podczas obróbki w wysokiej temperaturze, takiej jak austenityzacja i wyżarzanie, jest kluczowa. Często osiąga się to przy użyciu kontrolowanych atmosfer, pieców próżniowych lub kąpieli solnych.

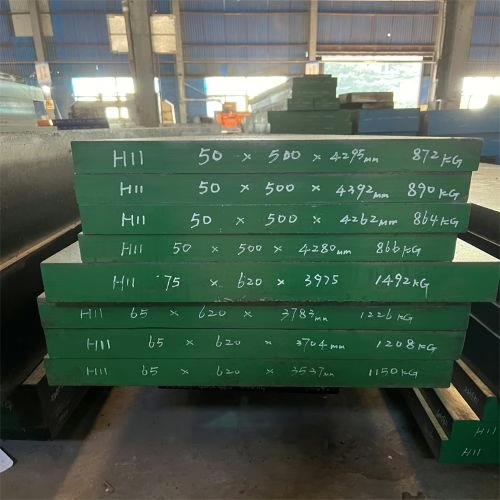

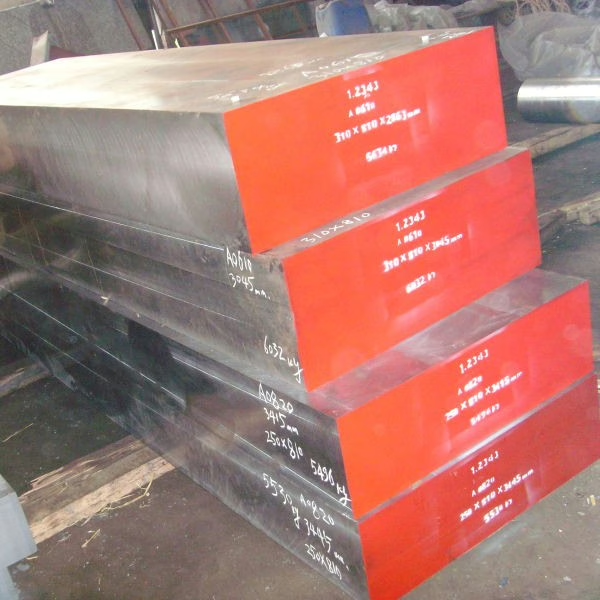

5. Formy i wymiary dostaw

Dostarczana przez nas stal narzędziowa H11 jest dostępna w różnych formach, w tym pręty okrągłe, blachy, płyty, płaskowniki, pręty kwadratowe i bloki. Wymiary płaskownika wahają się od: szerokość 20–600 mm × grubość 20–400 mm × długość 1000–5500 mm. Wymiary pręta okrągłego wahają się od średnicy 20–400 mm × długość 1000–5500 mm. Wymiary bloku uzyskuje się poprzez cięcie płaskownika.

W przypadku mniejszych rozmiarów, takich jak pręty okrągłe o średnicy mniejszej niż 70 mm, stosujemy proces walcowania na gorąco. W przypadku rozmiarów większych niż 70 mm oferujemy produkty kute.

Testy UT: wrzesień 1921-84 D/d, E/e.

Wykończenie powierzchni: oryginalne czarne, łuszczone, obrabiane maszynowo/toczone, polerowane, szlifowane lub frezowane wykończenie powierzchni.

Stan zapasów: Nie utrzymujemy zapasów stali narzędziowej H11. Organizujemy produkcję na podstawie zamówień klientów.

Czas dostawy: Materiały do pieców łukowych elektrycznych (EAF) to 30-45 dni. Materiały ESR to około 60 dni.

- Bringas, JE (red.). (2004). Podręcznik porównawczych światowych norm stali (wydanie 3, str. 434). ASTM International. ↩︎

- Murray, GT (red.). (1997). Podręcznik doboru materiałów do zastosowań inżynierskich. Wydawnictwo CRC Press. ↩︎

Często zadawane pytania

Stal H11 to przede wszystkim stal narzędziowa do pracy na gorąco chłodzona powietrzem, często określana jako DIN 1.2343 lub JIS SKD6. Jest to stal narzędziowa do pracy na gorąco na bazie chromu, wysoko ceniona za wyjątkową wytrzymałość i zdolność do zachowania swoich właściwości nawet w podwyższonych temperaturach. Jest szeroko stosowana w produkcji form.

Stal narzędziowa H11 charakteryzuje się doskonałą udarnością, wysoką odpornością na zmęczenie cieplne (znane również jako pękanie cieplne) oraz wysoką wytrzymałością, zachowując te właściwości w temperaturach dochodzących do 600°C. Charakteryzuje się również dobrą odpornością na zużycie, hartownością, plastycznością, odpornością na korozję, stabilnością w wysokich temperaturach, odpornością na utlenianie i spawalnością, co czyni ją stosunkowo łatwą w obróbce.

Stal H11 jest uznawana na całym świecie pod różnymi oznaczeniami, w tym DIN 1.2343 (Niemcy), JIS SKD6 (Japonia) i BH11 (Norma Brytyjska). W USA jest zgodna z normami takimi jak ASTM A681, FED QQ-T-570, SAE J437, SAE J438, SAE J467, a jej oznaczenie w UNS to T20811.

Stal H11 zawiera mniej wanadu niż stal H13. Dzięki temu stal H11 charakteryzuje się wyższą wytrzymałością i lepszą odpornością na pękanie zmęczeniowe cieplne (lepiej znosi powtarzające się cykle nagrzewania i chłodzenia) w porównaniu ze stalą H13, choć może mieć nieco mniejszą odporność na zużycie i odpuszczanie.

Stal H11 jest często wybierana, gdy zastosowanie wymaga maksymalnej odporności na pękanie i szok termiczny, szczególnie w przypadku stosowania chłodzenia wodnego lub częstych cykli nagrzewania i chłodzenia. Jej wyższa wytrzymałość i ogólnie łatwiejsza obróbka skrawaniem (dzięki niższej twardości) również sprawiają, że jest ona korzystniejszym wyborem niż stal H13 w niektórych projektach.

Stal narzędziowa H11 jest często stosowana w obróbce na gorąco, gdzie wymagana jest wysoka odporność na pękanie. Do najważniejszych zastosowań należą matryce do odlewów ciśnieniowych (szczególnie do stopów aluminium i magnezu), matryce kuźnicze, stemple do obróbki na gorąco, ostrza nożyc do obróbki na gorąco oraz narzędzia do wytłaczania. Jest również wykorzystywana w przemyśle lotniczym do produkcji kluczowych elementów konstrukcyjnych, takich jak podwozia samolotów.

Tak, stal H11 jest powszechnie stosowana w produkcji form do tworzyw sztucznych, szczególnie do części wkładanych do form.

Stal narzędziowa H11 jest powszechnie dostępna w postaci prętów okrągłych, arkuszy, płyt i płaskowników. Może być również dostarczana w postaci kęsów, kęsów, drutu, kształtowników, zwojów i rur. Stan powierzchni może być różny, w tym: oryginalna czarna, łuszczona, polerowana, obrabiana mechanicznie, walcowana na gorąco, szlifowana, toczona, ciągniona lub walcowana na zimno.

W celu hartowania, stale narzędziowe H11 są zazwyczaj podgrzewane wstępnie do temperatury 816°C (1500°F), a następnie bezpośrednio podgrzewane do 1010°C (1850°F), gdzie są wygrzewane w tej temperaturze przez 15 do 40 minut. Proces hartowania kończy się hartowaniem w powietrzu, co jest skuteczne ze względu na bardzo wysoką hartowność stali H11. Niektóre metody obejmują chłodzenie olejowe po hartowaniu z 1000°C do 1030°C, a następnie chłodzenie w powietrzu.

Odpuszczanie stali H11 odbywa się w temperaturach od 538 do 649°C (od 1000 do 1200°F), co pozwala na uzyskanie twardości Rockwella C wynoszącej od 54 do 38. Zdecydowanie zaleca się dwukrotne odpuszczanie, przy czym każdy etap odpuszczania trwa jedną godzinę w wybranej temperaturze, po czym następuje chłodzenie w powietrzu.

Tak, stale narzędziowe H11 można spawać metodami konwencjonalnymi. Często jednak konieczne są specjalne procedury, w tym podgrzewanie wstępne i stosowanie materiałów dodatkowych o składzie odpowiadającym materiałowi bazowemu. Należy pamiętać, że stal H11 jest podatna na pękanie wodorowe (HIC) ze względu na wysoką zawartość dodatków stopowych i hartowność, dlatego precyzyjna kontrola temperatury (np. 310-370°C w przypadku napawania) podczas spawania jest kluczowa.

Tak, stal H11 charakteryzuje się dobrą skrawalnością. Jej współczynnik skrawalności wynosi około 75% do 80% w porównaniu ze stalą węglową 1% i około 75% stali narzędziowych grupy „W”. Często uważa się ją za łatwiejszą w obróbce niż stal H13 ze względu na jej niższą twardość.

Stale narzędziowe H11 są zazwyczaj kute w temperaturze około 1121°C (2050°F). Kucie w temperaturze poniżej 899°C (1650°F) nie jest zalecane. Dokładna temperatura może się różnić i zazwyczaj mieści się w zakresie od 1000 do 1200°C (1832 do 2192°F), w zależności od pożądanych właściwości odkształcających.

Tak, stal H11 stanowi doskonałe podłoże do powlekania PVD. Do azotowania preferowana jest mała strefa dyfuzyjna i należy unikać tworzenia warstw złożonych i utlenionych. Stal H11 nadaje się do azotowania kąpielowego, gazowego i plazmowego i może być azotowana w temperaturach 500-600°C w celu uzyskania twardej powierzchni. Badania dotyczyły również powłok TiN na stali H11.

Twardość stali H11 po obróbce cieplnej zmienia się w zależności od odpuszczania. W zastosowaniach ogólnych typowa jest twardość 50-54 HRC. Po schłodzeniu w powietrzu z temperatury 1038°C (1900°F) przez 45 minut, twardość może osiągnąć nawet 57 HRC. Odpuszczanie w zakresie temperatur 538-649°C (1000-1200°F) może skutkować twardością w skali Rockwella C od 54 do 38.

Tak, stal narzędziową H11 (a konkretnie DIN 1.2343 / AISI H11) można wytwarzać w procesach wytwarzania przyrostowego, takich jak laserowe łączenie proszków (LPBF). Badania wskazują, że późniejsza obróbka cieplna po procesie LPBF pozwala na precyzyjne dostosowanie mikrostruktury i twardości tych stali wytwarzanych przyrostowo.

Stal H11 ma zazwyczaj ocenę 60-70% w porównaniu do hartowanej w wodzie stali narzędziowej W1 (która stanowi punkt odniesienia przy obrabialności 100% dla stali narzędziowych).

Potrzebujesz wysokowydajnej stali narzędziowej H11?

Z ponad 20 lat doświadczenia w specjalistycznym kuciu, Aobo Steel to Twoje zaufane źródło wysokiej jakości stali narzędziowej H11. Dostarczamy trwałe, wysokowydajne materiały, precyzyjnie dopasowane do wymagań Twojego zastosowania. Nasi oddani specjaliści służą fachową poradą i zapewnią Ci idealne rozwiązanie H11.

Chcesz udoskonalić swój projekt dzięki doskonałej stali narzędziowej H11? Wypełnij poniższy formularz, aby skontaktować się z naszym zespołem. Przygotujemy spersonalizowaną wycenę i odpowiemy na wszystkie Twoje pytania.