The heat treatment of M2 steel plays a significant role in its excellent performance as a cutting tool. The heat treatment of M2 involves transforming the fully annealed microstructure (primarily composed of ferrite and alloy carbides) into a quenched and tempered martensitic microstructure containing carbides, thereby achieving the desired cutting tool properties. This process typically consists of four main stages: preheating, austenitizing, quenching, and tempering.

1. Preheating

Preheating is an essential step performed on virtually all tool steels. Its purpose is to precondition the molecules within the part, allowing for a more uniform and accepted transformation during subsequent heating, and significantly reducing the risk of thermal shock and cracking. While preheating doesn’t directly harden the steel, it’s a vital preparatory step in the M2 tool steel heat treatment process.

M2 steel is typically preheated in two stages, with the first preheating temperature ranging from 650 to 760°C (1200 to 1400°F). The second preheating temperature ranges from 815 to 900°C (1500 to 1650°F).

The insulation time is 10 to 12 minutes, so that the entire cross-section of the M2 material reaches a uniform temperature.

2. Austenitizing (Hardening)

Austenitizing is the second step and is a time/temperature-dependent reaction. The austenitizing range for M2 steel is typically 1150 to 1290°C (2100 to 2350°F). For maximum toughness and minimum distortion, heat quickly to 1177°C (2150°F); for maximum M2 steel hardness and wear resistance, heat to 1232°C (2250°F).

The insulation time is very short. An example of tests on 1″x1″x1″ (25mmx25mmx25mm) M2 blocks showed an optimum soak time of 4.5 minutes, with slight overcooking observed at 6 minutes. For a 6″ (150mm) thick cross section, a maximum of 5 to 6 minutes is typical.

3. Quenching

Following austenitizing, quenching is necessary to transform the austenite into martensite, the hard matrix structure desired in M2 tool steel.

M2 can be effectively quenched in oil, air, or a neutral salt bath. Air cooling is the least drastic and can be sufficient for smaller or thinner M2 sections to achieve the martensitic condition. Oil quenches are typically followed by air cooling to near ambient temperature.

When the M2 temperature drops to 65°C (150°F), the next step of tempering must be performed immediately to avoid residual austenite stabilization and prevent cracking. Due to their high alloy content, M2 and other high-speed steels can contain significant amounts of retained austenite after quenching. This retained austenite is unstable and can spontaneously transform to untempered, brittle martensite at room temperature, leading to dimensional instability and reduced toughness.

4. Tempering

Tempering is the final critical step. It serves to relieve stress, increase its toughness, and develop secondary hardness. M2 should undergo at least two tempering processes, and three tempering processes will further improve performance. This multi-stage process is crucial to optimizing the transformation of retained austenite to fresh martensite and to temper this newly formed martensite. A single temper of the same duration is less beneficial.

The temperature for the first tempering of M2 is 565°C (1050°F). The temperature for the second tempering is 550°C (1025°F). After each tempering process, wait for M2 to cool to room temperature before performing the following tempering process.

Tempering curve for M2 high-speed tool steel. To optimize the transformation of retained austenite to fresh martensite during the tempering sequence, the high (right) side of the secondary hardness peak curve is preferred, and the low (left) side should be avoided.1

Tempering Temperatures and achieved hardness.Based on using an austenizing temperature of 2250°F (1230∘°C)2

| Tempering Temperature | Oil Quenched Rockwell Hardness Rc | Air Quenched Rockwell Hardness Rc |

| 300°F 150℃ | 66 | 66.5 |

| 400°F 205℃ | 65 | 65 |

| 500°F 260℃ | 64 | 63.5 |

| 600°F 315℃ | 63 | 62.5 |

| 700°F 370℃ | 62.5 | 62.5 |

| 800°F 425℃ | 63 | 62.5 |

| 900°F 480℃ | 65 | 63.5 |

| 1000°F 540℃ | 66 | 63.5 |

| 1050°F 565℃ | 66 | 63.5 |

| 1100°F 595℃ | 64.5 | 61.5 |

| 1150°F 620℃ | 62 | 60 |

| 1200°F 650℃ | 53.5 | 53 |

5. Microstructure and Properties of Heat-Treated M2 Tool Steel

- As-Quenched Microstructure: The steel after austenitizing and quenching is in a highly stressed state and susceptible to cracking. It consists primarily of martensite and retained austenite, along with undissolved alloy carbides. The martensite is initially highly stressed due to volumetric expansion during transformation from austenite.

- Hardened and Tempered Microstructure: The final microstructure consists of tempered martensite containing various dispersions of iron and alloy carbides. This refined grain structure, with well-dispersed, hard "secondary hardening" carbides, contributes to M2's combination of hardness, toughness, and excellent wear resistance.

- Hardness: M2 typically achieves a hardness of 60-65 HRC, with specific tempering cycles yielding high hardness (e.g., 65.5 HRC after tempering at 538°C/1000°F).

- Toughness: Tempering significantly increases the toughness of the steel.

- Wear Resistance: The presence of specific alloy carbides (e.g., M6C, M23C6, MC types) formed during secondary hardening contributes significantly to its wear resistance.

- ASM International. (1989). ASM Handbook, Volume 16: Machining (p. 122). ASM International. ↩︎

- Bryson, W. E. (2018). Heat Treatment, Selection, and Application of Tool Steels (p. 82). Carl Hanser Verlag GmbH & Co. KG. ↩︎

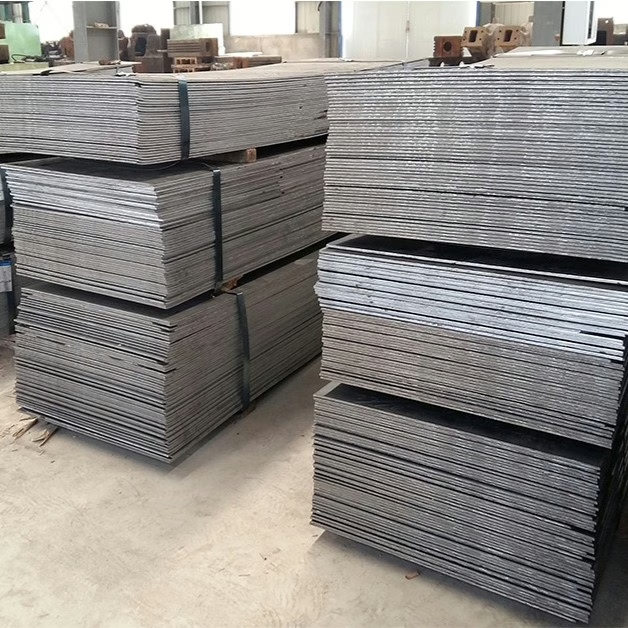

Our company, Aobo Steel, is a high-quality tool steel supplier with over 20 years of experience in forging tool steel in China. We have some tool steel in stock. If you would like to purchase M2 tool steel or have any questions about M2 steel, please feel free to contact us.