H11 tool steel is an air-cooling hardening hot work tool steel. It has excellent toughness, thermal strength, fatigue performance, and wear resistance at medium temperatures. Additionally, it retains some toughness in the quenched state and demonstrates strong resistance to thermal fatigue. When air-quenched at lower austenitizing temperatures, it exhibits minimal heat treatment deformation and a low tendency to form oxide skin. H11 tool steel can effectively resist the corrosion of molten aluminum, making it a popular choice for manufacturing aluminum die casting molds, hot extrusion tools, stamping and forging molds, and plastic molds.

The designation for this steel is H11 in the U.S. ASTM A681 system. Similarly, other national standards use comparable designations, such as ISO X37CrMoV5-1, Japan/JIS SKD6, USA/UNS T20811, Germany/DIN X38CrMoV5-1, Germany/W-Nr. 1.2343, Czech Republic (CSN) 19552, and China/GB 4Cr5MoSiV.

1. Applications

- Die Casting Dies

- Forging Dies

- Extrusion Tools

- Hot Shear Blades:

- Aerospace Components

2. Chemical composition1

| C | Mn | Si | Cr | Mo | V |

| 0.33 – 0.43% | 0.20 – 0.60% | 0.80 – 1.25% | 4.75 – 5.50% | 1.10 – 1.60% | 0.30 – 0.60% |

H11 tool steel equivalent grades and the compositions

| Grades | C | Si | Mn | P | S | Cr | Mo | V |

| DIN 1.2343 | 0.33 – 0.43% | 0.80 – 1.25% | 0.20 – 0.60% | ≤ 0.030% | ≤ 0.030% | 4.75 – 5.50% | 1.10 – 1.60% | 0.30 – 0.60% |

| JIS SKD6 | 0.32 – 0.42% | 0.80 – 1.20% | 0.20 – 0.50% | ≤ 0.030% | ≤ 0.030% | 4.50 – 5.50% | 1.00 – 1.50% | 0.30 – 0.60% |

| GB 4Cr5MoSiV | 0.33 – 0.43% | 0.80 – 1.20% | 0.20 – 0.50% | ≤ 0.030% | ≤ 0.030% | 4.75 – 5.50% | 1.10 – 1.60% | 0.30 – 0.60% |

3. Properties2

Tool steel H11 possesses an exceptional combination of attainable hardness, red hardness (hot hardness), toughness, and wear resistance.

- Strength: It can be heat-treated to yield strengths of 0.2% well above 1380 MPa (200 ksi) and ultimate tensile strengths exceeding 2070 MPa (300 ksi).

- Hardness: Normal working hardnesses typically range from 40 to 55 HRC. For applications such as aluminum die casting, a preferred hardness of 47 HRC is noted. In die casting, H11 dies can be hardened to 42–52 HRC, inserts and cores to 46–52 HRC, plungers to 46–50 HRC, slides to 46–52 HRC, shot sleeves to 44–48 HRC, and nozzles to 32–42 HRC. For hot forging punches and dies, hardness typically ranges from 44–48 HRC. Hot-rolling mill rolls (for short runs and low temperatures) use H11 at 40–48 HRC. Hot swaging dies are typically 48–52 HRC.

- Hot Hardness/Red Hardness: Good temper resistance, maintaining high hardness and strength at elevated temperatures. It resists softening during continuous exposure to temperatures up to 540 °C (1000 °F). While its hot hardness is lower than some other hot-work steels, such as H19 or H21, it still retains hardness better than other medium-alloy steels at higher temperatures. Hot Hardness/Red Hardness is a very important property for hot-work tool steels.

- Toughness and Ductility: Good ductility and impact strength. It has better resistance to brittle fracture compared to higher alloy content steels such as H14, H19, and H21. Electroslag remelting (ESR) or vacuum arc remelting (VAR) melting processes can significantly improve the ductility and toughness .

- Fatigue Resistance: This material can provide high levels of fatigue resistance and thermal stability over a temperature range of 75 to 540°C (167 to 1000°F). Compared with 4340 steel that has undergone the same high-intensity heat treatment, H11 has better fatigue strength.

- Wear Resistance: Its wear resistance is lower than that of H13.

- Weldability: It is readily weldable, even in heavy sections.

- Machinability: Good machinability, rated around 70% of a standard 1% carbon steel.

- Thermal properties: It has a relatively low thermal expansion coefficient and a thermal conductivity of 26 W/m·K.

- Corrosion Resistance: Above-average resistance to oxidation and corrosion.

- Heat Checking Resistance: Good resistance to thermal fatigue or heat checking.

Interested in H11 tool steel? Fill out the form below to get in touch with us now!

4. H11 Tool Steel Heat Treatment

Precise H11 tool steel heat treatment is crucial for achieving its optimal performance as a 5% chromium hot-work die steel and ultrahigh-strength steel, similar to H11 Modified and H13. This process tunes the microstructure for demanding factory tooling.

4.1 Forging

This steel is easily forged, with a suitable forging temperature range of 1120 to 1150°C (2050 to 2100°F). We recommend preheating the billet to 790 to 815°C (1450 to 1500°F), then uniformly heating it to the forging temperature. The forging temperature must NOT be lower than 925°C (1700°F). If the temperature drops near this level, it must be reheated before continuing the forging process.

4.2 Austenitizing(Hardening)

Austenitizing, the primary hardening step, involves heating to transform its structure into austenite. This allows uniform conversion and dissolution of alloying elements and carbides.

- Preheating: Preheating H11 to 760-815 °C (1400-1500 °F) before austenitizing is recommended to minimize thermal shock and cracking, especially for this high-alloy material.

- Austenitizing Temperatures and Soaking Times: The Austenitizing Temperature is 995 to 1025 °C (1825 to 1875 °F). The soaking time is 20 minutes + 5 minutes per 25 mm (1 inch) of thickness.

Holding at the austenitizing temperature ensures uniform transformation and dissolution.

4.3 Quenching

After austenitizing, H11 steel is rapidly quenched to form hard martensite. H11 is an air-hardening steel, providing uniform hardening through large sections with minimal residual stress and dimensional change. Air cooling is the standard and preferred method for H11 tool steel. While air cooling is standard, oil quenching from 995 °C (1825 °F) is a possible alternative. H11 and other hot work tool steels must never be water quenched, as this can lead to cracking.

4.4 Tempering

After hardening, tempering H11 tool steel by reheating to a lower temperature is crucial for improving toughness, relieving stress, and stabilizing properties. Steel H11 is a secondary hardening steel. It achieves its best performance when tempered at temperatures above 510°C (950°F). We recommend performing multiple tempering treatments on it to achieve optimal toughness and extend tool life. Allow parts to cool to room temperature between each tempering cycle to minimize residual austenite.

Table of Hardness and Tempering Temperature for H11 Steel

| Tempering Temperature | Rockwell C |

| As quenched | 56 |

| 700°F/370°C | 54 |

| 800°F/425°C | 55 |

| 900°F/480°C | 57 |

| 1000°F/540°C | 56 |

| 1100°F/595°C | 46 |

| 1200°F/650°C | 36 |

4.5 Annealing

The annealing temperature ranges from 845 to 900°C (1550-1650°F). The cooling rate is 22-40°C/h (40-75°F/h). The hardness after annealing is 192-229 HB.

4.6 Other Important H11 Heat Treatment Considerations

- Normalizing: This process is generally not recommended for H11 or H13 tool steels due to the high risk of cracking, especially with surface decarburization.

- Stress-Relief: After H11 has undergone processing, such as grinding, welding, or EDM (electrical discharge machining), we strongly recommend that it undergo stress relief treatment at 650°C. This treatment should be carried out at a temperature 14–28°C (25–50°F) lower than the previous tempering temperature. After stress relief, cool slowly at a maximum rate of 300°C/h to prevent the formation of new stresses.

- Cryogenic Treatment: Sub-zero treatment (e.g., -73°C / -100°F) can reduce retained austenite; however, H11’s high tempering temperatures usually make it unnecessary to achieve the maximum secondary hardening response.

- Surface Protection: Protecting its surfaces from oxidation and decarburization during high-temperature treatments, such as austenitizing and annealing, is vital. This is often achieved using controlled atmospheres, vacuum furnaces, or salt baths.

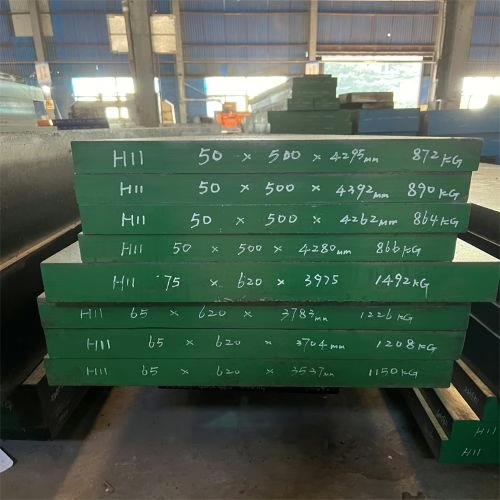

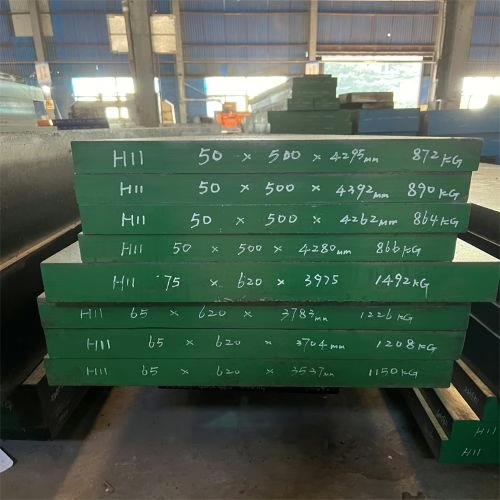

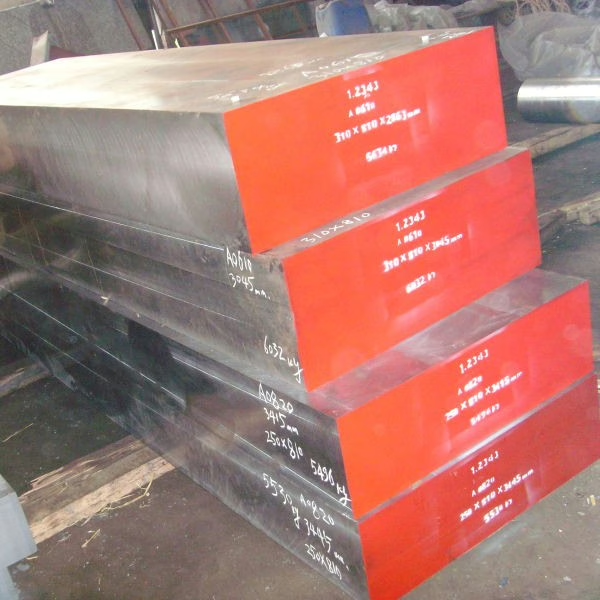

5. Supply forms and dimensions

The H11 tool steel we supply is available in various forms, including round bars, sheet plates, slabs, flat bars, square bars, and blocks. The dimensions of the flat bar range from: width 20–600 mm × thickness 20–400 mm × length 1,000–5,500 mm. The dimensions of the round bar range from a diameter of 20–400 mm × a length of 1,000–5,500 mm. The block dimensions are obtained by cutting the flat bar.

For smaller sizes, such as round bars with a diameter less than 70 mm, we use the hot-rolled process. For sizes greater than 70 mm, we offer forged products.

UT testing: Sep 1921-84 D/d, E/e.

Surface Treatment: original black, peeled, machined/turned, polished, grounded, or milled surface finishes.

Inventory Status: We do not maintain a stock of H11 tool steel. We arrange production based on customer orders.

Delivery time: Electric Arc Furnace (EAF) materials are 30-45 days. ESR materials are approximately 60 days.

- Bringas, J. E. (Ed.). (2004). Handbook of Comparative World Steel Standards (3rd ed., p. 434). ASTM International. ↩︎

- Murray, G. T. (Ed.). (1997). Handbook of Materials Selection for Engineering Applications. CRC Press. ↩︎

FAQ

H11 steel is primarily an air-cooling type hot work mold steel, often referred to as DIN 1.2343 or JIS SKD6. It is a chromium-based hot work tool steel highly valued for its exceptional toughness and ability to retain its properties even at elevated temperatures. It is used extensively in the manufacturing of molds.

H11 tool steel is noted for its excellent impact toughness, strong resistance to thermal fatigue (also known as heat checking), and high strength, maintaining these qualities at temperatures approaching 600°C. It also offers good wear resistance, hardenability, plasticity, corrosion resistance, high temperature stability, oxidation resistance, and weldability, making it relatively easy to process.

H11 steel is recognized globally under various designations, including DIN 1.2343 (Germany), JIS SKD6 (Japan), and BH11 (British Standard). In the USA, it aligns with standards like ASTM A681, FED QQ-T-570, SAE J437, SAE J438, SAE J467, and its Unified Numbering System (UNS) designation is T20811.

H11 steel contains less vanadium than H13 steel. This results in H11 having higher toughness and superior resistance to thermal fatigue cracking (better handling of repeated heating and cooling cycles) compared to H13, though it might have slightly less wear and temper resistance.

H11 steel is often chosen when the application demands maximum resistance to cracking and thermal shock, particularly when water cooling is involved in service or under frequent heating and cooling cycles. Its superior toughness and generally easier machinability (due to lower hardness) also make it a favorable choice over H13 for certain projects.

H11 tool steel is frequently used in hot tooling applications that require high resistance to cracking. Key applications include die casting dies (especially for aluminum and magnesium alloys), forging dies, hot punches, hot shear blades, and extrusion tooling. It is also utilized in the aerospace industry for critical structural components, such as aircraft landing gear.

Yes, H11 steel is widely used in the manufacturing of plastic molds, particularly for the insert parts of the mold.

H11 tool steel is commonly available as round bars, sheets, plates, and flat bars. It can also be supplied as slabs, billets, wire, shapes, steel coils, and pipes. Surface conditions vary, including original black, peeled, polished, machined, hot rolled, ground, turned, drawn, or cold rolled.

For hardening, H11 tool steels are generally preheated to 816°C (1500°F) and then directly heated to 1010°C (1850°F), where they are held at that temperature for 15 to 40 minutes. The hardening process is completed by air-quenching, which is effective due to H11’s very high hardenability. Some methods involve oil cooling after quenching from 1000 °C to 1030°C, followed by air cooling.

Tempering of H11 steel is performed at temperatures ranging from 538 to 649°C (1000 to 1200°F) to achieve a Rockwell C hardness between 54 and 38. Double tempering is highly recommended, with each tempering step lasting one hour at the chosen temperature, followed by air cooling.

Yes, H11 tool steels can be welded using conventional methods. However, special procedures are often necessary, including pre-heating and using filler materials that match the base material’s composition. It’s important to note that H11 is susceptible to hydrogen-induced cracking (HIC) due to its high alloy content and hardenability, so precise temperature control (e.g., 310-370°C for hardfacing) during welding is crucial.

Yes, H11 steel exhibits good machinability. Its machinability rate is approximately 75% to 80% compared to 1% carbon steel and about 75% of “W” group tool steels. It is often considered easier to machine than H13 steel because of its lower hardness.

H11 tool steels are typically forged at around 1121°C (2050°F). Forging below 899°C (1650°F) is not recommended. The precise temperature can vary, generally falling within a range of 1000 to 1200°C (1832 to 2192°F), depending on desired deformation properties.

Yes, H11 steel serves as an excellent substrate for PVD coating. For nitriding, a small diffusion zone is preferred, and the formation of compound and oxidized layers should be avoided. H11 is suitable for bath, gas, and plasma nitriding processes and can be nitrided at temperatures of 500-600°C to achieve a hard surface. Studies have also explored TiN coatings on H11 steel.

The hardness of H11 steel post-heat treatment varies with tempering. For general applications, a hardness of 50-54 HRC is common. When air-cooled from 1038°C (1900°F) for 45 minutes, it can reach up to 57 HRC. Tempering within the range of 538-649°C (1000-1200°F) can result in a Rockwell C hardness from 54 down to 38.

Yes, H11 tool steel (specifically DIN 1.2343 / AISI H11) can be produced through additive manufacturing processes, such as Laser Powder Bed Fusion (LPBF). Research indicates that subsequent heat treatments after LPBF can be used to precisely tailor the microstructure and hardness of these additively manufactured steels.

H11 is typically rated at 60-70% when compared to water-hardening tool steel W1 (which serves as a benchmark at 100% machinability for tool steels).

Need High-Performance H11 Tool Steel?

With over 20 years of specialized forging experience, Aobo Steel is your trusted source for premium H11 tool steel. We deliver durable, high-performance materials precisely tailored to your application’s demands. Our dedicated specialists are here to provide expert advice and ensure you get the perfect H11 solution.

Ready to enhance your project with superior H11 tool steel? Fill out the form below to connect with our team. We’ll provide a personalized quote and answer all your questions.