Heat treat D2 steel typically involves three basic steps: heating (austenitization), rapid cooling...

D2 tool steel is an important member of the high-carbon, high-chromium cold-worked tool steel...

No, 4140 steel is not stainless steel. It is consistently classified as a medium-carbon low-alloy...

HSS primarily stands for High-Speed Steel or High-Speed Tool Steel. It is a crucial category of...

4140 steel exhibits varying hardness levels under different conditions and treatment states...

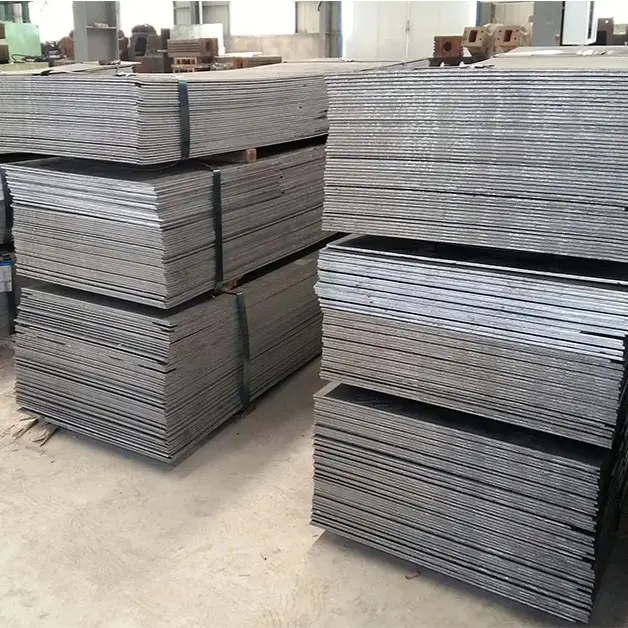

As a professional tool steel supplier, we will provide you with a detailed introduction to the...

The core difference is this: D2 tool steel is your go-to for cold-work applications demanding...

When you’re looking at S7 tool steel and 4140 alloy steel, the most important thing to know...

The fundamental difference between S7 and A2 tool steel is that S7 is engineered for excellent...