D2 Tool Steel | 1.2379 | SKD11

AOBO STEEL – Trusted Global Tool Steel Supplier

D2 tool steel is a high-carbon, high-chromium, air-hardening cold-work tool steel. Its characteristics include: high hardenability, high hardness and wear resistance, good high-temperature oxidation resistance, impact resistance after quenching and tempering, and minimal deformation during heat treatment. These characteristics are utilized to manufacture large-section, complex-shaped cold-worked dies, tools, and gauges that require high precision and long service life.

The designation in the U.S. ASTM A681 system is D2. The grade is also AISI D2 tool steel in the AISI system. Similar designations in other national standards include ISO 160CrMoV12, Japan/JIS SKD11, USA/UNS T30402, Germany/DIN X155CrMo12-1, Germany/W-Nr. 1.2379, Czech Republic (CSN) 19221, and China/GB Cr12Mo1V1 or Cr12MoV.

1. Applications

- Blanking Dies and Punches

- Forming Dies and Punches

- Drawing Dies

- Lamination Dies

- Shear Blades and Slitter Knives

- Cold Extrusion Dies and Punches

- Rolls

- Gauges and Burnishing Tools

- Plastic Molds

- Hot Trimming of Forgings

- Structural Component Parts

2. D2 Steel Composition1

| C | Cr | Mo | V | Mn | Si | P | S |

| 1.40 – 1.60% | 11.00 – 13.00% | 0.70 – 1.20% | 0.50 – 1.10% | 0.10 – 0.60% | 0.10 – 0.60% | ≤ 0.030% | ≤ 0.030% |

The equivalent grades’ composition

| C | Si | Mn | Cr | Mo | V | P | S | |

| Germany/W-Nr. 1.2379 | 1.45 – 1.60% | 0.10 – 0.60% | 0.20 – 0.60% | 11.00 – 13.00% | 0.70 – 1.00% | 0.70 – 1.00% | ≤0.030% | ≤0.030% |

| Japan/JIS SKD11 | 1.40 – 1.60% | ≤0.40% | ≤0.60% | 11.00 – 13.00% | 0.80 – 1.20% | 0.20 – 0.50% | ≤0.030% | ≤0.030% |

| China/GB Cr12Mo1V1 | 1.40 – 1.60% | ≤0.60% | ≤0.60% | 11.00 – 13.00% | 0.70 – 1.20% | 0.50 – 1.10% | ≤0.030% | ≤0.030% |

3. D2 Steel Heat Treatment

As William E. Bryson describes in his book Heat Treatment, Selection, and Application of Tool Steels, the heat treating D2 tool steel is often compared to cooking, where precise control of time and temperature is critical to avoid undercooking (leading to a lack of hardness) or overcooking (destroying molecular structure and causing brittleness). The following steps outline the process.

D2 tool steel critical and austenization temperatures

| Ac1 | Ac3 | Ar1 | Ar3 | Austenization Temperature |

| 788℃ | 845℃ | 769℃ | 744℃ | 1010−1024℃ |

3.1 Material Preparation and Preheating

Before heat treatment, the material should be thoroughly degreased and preferably wrapped in stainless steel foil to protect its surface. Because of the high chromium content and low thermal conductivity of this steel, it should be slowly and evenly preheated to the target temperature to minimize the risk of cracking during heating. The target temperature is 1200°F (650°C), and the heating time is 10 to 15 minutes.

The purpose of the entire preheating process is to ensure that heat is distributed uniformly throughout the material, allowing internal stresses to be released before the material becomes too soft and its plasticity increases, thereby preventing deformation.

3.2 Austenitizing (Hardening)

This is the second step in heat treatment, during which the material’s structure changes from ferrite-pearlite to austenite, and various complex alloy carbides are dissolved. The heating temperature for this step is 1850°F (1010°C), with a soak time of 1 hour per 1 inch (25 mm) of cross-section. This soak time ensures that the austenitization process occurs uniformly. However, it is important to note that an excessively long soak time, even just a few minutes, may have a negative impact on the steel.

3.3 Quenching

D2 tool steel is an air-hardening steel whose advantage lies in minimizing deformation and dimensional changes during the formation of martensite. The process involves the following steps: After soaking, the material is rapidly cooled to approximately 150°F (65°C). During this process, when the temperature reaches 1050°F (565°C) and before the material transforms into a hardened structure at 400°F (205°C), the workpiece can be removed from the foil packaging and placed on a cooling rack. Caution must be exercised to avoid putting the material directly on a cold table surface, as this can cause localized temperature fluctuations and result in deformation. From a microstructural perspective, this process transforms the steel’s internal structure into finer-grained martensite, imparting excellent wear resistance to D2.

After proper quenching, the material still contains a certain proportion of “residual austenite,” with the optimal martensite content ranging from 95% to 96%.

3.4 Tempering

Tempering improves the toughness of steel, reduces internal stress, and makes D2 tool steel secondary hardening. Tempering must be performed immediately when the material temperature drops to 125°F to 150°F (52°C to 65°C).

If D2 is only tempered once, the tempering temperature is 400°F (205°C) to achieve a Rockwell hardness of 61-62HRC.

We recommend using a secondary tempering process for D2, which can improve its wear resistance by 20-30%.

In the secondary tempering process, the first tempering temperature is 960°F (515°C) for 2 hours per inch (25 mm) of cross-section. Before the second tempering, i.e., during the interval between the first and second tempering, the material must be allowed to cool to room temperature before the second tempering. This period may last several hours. It may also take several days, but the key point is that the second tempering must NOT begin at 150°F (65°C), which is a completely different temperature from the single tempering mentioned earlier. The second tempering temperature is 900°F (480°C) for 2 hours per inch of cross-section. The second tempering achieves a Rockwell hardness of 58 HRC.

While D2 has weak secondary hardness, tempering at higher temperatures (e.g., ~550°C/1020°F) can be used to achieve a hardness of 60 HRC, thereby improving stability during nitriding or other surface hardening methods. However, this can lead to increased retained austenite and grain growth, potentially decreasing toughness and causing microstructural instabilities.

Table of Hardness and Tempering Temperature for D2 Steel

| Tempering Temperature | Rockwell C |

| As quenched | 64 |

| 300°F/150°C | 62 |

| 400°F/205°C | 61 |

| 500°F/260°C | 60 |

| 600°F/315°C | 59 |

| 700°F/370°C | 58 |

| 800°F/425°C | 58 |

| 900°F/480°C | 58 |

| 1000°F/540°C | 55 |

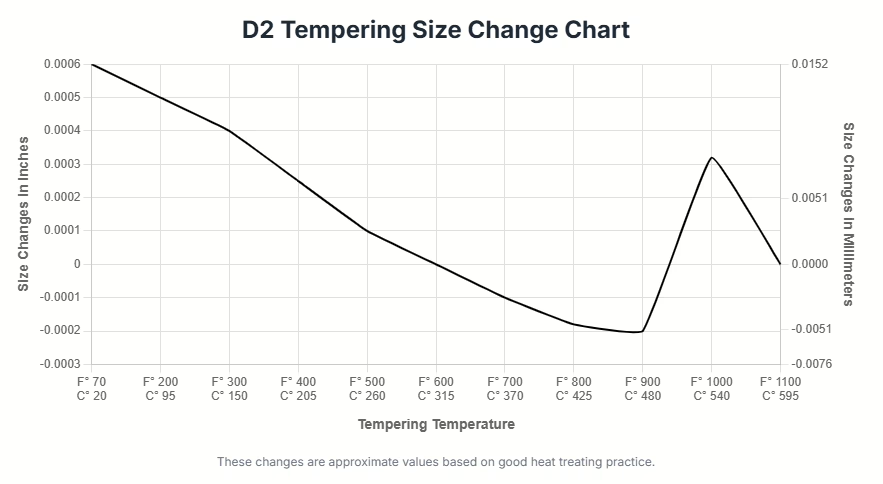

D2 Steel Dimension Change Curve During Heat Treatment

3.5 Cryogenic/Sub-Zero Treatment (Optional)2

This process is designed to eliminate or reduce residual austenite and enhance material dimensional stability. Since D2 tool steel can retain a significant amount of austenite (up to 20%) after standard heat treatment, this can lead to dimensional instability as retained austenite spontaneously transforms into untempered martensite over time at room temperature.

The process involves the following steps: After stress relief treatment (approximately 150°C), the material is cooled to an extremely low temperature (approximately -300°F/-184°C), approaching or below the final Mf temperature. Subsequent tempering is still required to prevent brittleness caused by the newly formed fresh martensite.

This process creates a more compact molecular structure within the material (reducing friction, heat, and wear), reduces residual stress, and enhances tensile strength, toughness, and dimensional stability, significantly improving material performance.

3.6 Potential Issues

- Residual austenite can cause dimensional instability in materials, especially at higher austenitizing temperatures. Controlled quenching, precise hold times, and double and triple tempering are employed to manage this process.

- Factors such as non-uniform heating and cooling, phase transformations (especially martensite formation), and residual stress during heat treatment can cause deformation and cracking in materials. Therefore, it is important to ensure slow and uniform heating, proper quenching media, and stress relief treatment.

- D2 steel is susceptible to decarburization. We recommend heating D2 materials in a controlled neutral atmosphere, a vacuum, or a neutral salt furnace environment to prevent decarburization.

3.7 Forging

D2 tool steel should be preheated slowly and uniformly to 900 °C (1650 °F) before heating to forging temperatures. D2 has low thermal conductivity, so it must be heated slowly. Heating too quickly can cause the material to crack.

After preheating, the initial forging temperature for D2 steel is 980–1095 °C (1800–2000 °F). For large sections or heavy reductions, the higher end of this range should be used, while for smaller sections or lighter reductions, the lower end is more appropriate.

It is important to note that the temperature during the forging of D2 steel must not fall below 900°C (1650°F). If the temperature drops below this level, the steel must be reheated before forging.

D2 tool steel may partially melt at approximately 1150°C (2100°F), so the forging temperature must be strictly controlled.

Interested in D2 tool steel? Please complete the form below to contact us for technical support and to receive the latest quotes on D2 steel.

4. D2 Steel Properties

4.1 Basic Mechanical Properties

| Modulus of Elasticity | 0.2% Offset Yield Strength | Yield Strength | UTS |

| 203 GPa | 411 MPa | 350 MPa | 758 MPa |

It exhibits high compressive strength, particularly when tempered at lower temperatures. This strength is directly related to the hardness level; as the tempering temperature increases, both hardness and compressive strength tend to decrease.

4.2 Tensile Test Data3

| Modulus of Toughness | Fracture Strength | Displacement at Fracture | Gauge Length | Fracture Strain | Area Reduction |

| 81 MPa | 723 MPa | 0.61 mm | 30 mm | 1.97% | 1.30% |

4.3 Ductility and Toughness

- Material D2’s toughness is moderate, which is superior to grades like D3 tool steel. Compared with other D series steels with higher carbon content, D2 steel has a good balance of wear resistance and toughness.

- Tensile tests often show a ductile fracture mode, characterized by dimple-like structures. However, this material might exhibit a flat fracture surface with minimal necking and low area reduction (e.g., around 1.3% in some tests).

- The Modulus of Toughness has been measured at 81 MPa, with a fracture strain of 1.97%.

- D2 steel exhibits anisotropic strength and ductility, which is attributed to the elongation of primary alloy carbides during hot working. The maximum strength and ductility of D2 are typically along the rolling direction.

4.4 Dimensional Stability

- It exhibits minimal distortion compared to many other tool steels. When air quenched from the correct hardening temperature, the expansion or contraction is approximately 0.0005 inches per inch (or mm/mm).

- Factors like part geometry and existing distortions can influence the total movement.

- After grinding, welding, EDM, and other processes, stress relief tempering is strongly recommended. The tempering temperature is usually 14-28°C (25-50°F) lower than the final tempering temperature.

4.5 Wear Resistance

It has excellent abrasion resistance, often serving as a benchmark for other tool steels. This high wear resistance is directly attributed to the substantial volume of hard, chromium-rich carbides in its microstructure. This makes D2 a preferred material for tooling subjected to abrasive conditions and long production runs. Its wear resistance is noted to be about 30-40% improved over A2 tool steel.

4.6 Processing Considerations for D2 Steel

It has relatively poor machinability. If steel with a carbon content of 1% is rated as 100, then D2 is rated as 45 for machinability in the annealed state. It can be difficult to work and grind, and its weldability using traditional methods is very poor.

5. D2 Steel Advantages and Disadvantages

5.1 Advantages

- High Wear Resistance: The higher carbon and chromium content of D2 steel results in the formation of a large amount of chromium-rich carbides in its microstructure, giving it excellent wear resistance. Its wear resistance is 30% to 40% higher than that of A2 steel.

- Air-Hardening Characteristics: D2 steel is an air-hardening steel that allows for minimal deformation and displacement during the hardening process, making it suitable for applications with high dimensional tolerance requirements.

- Dimensional Stability: D2 exhibits good dimensional stability in heat treatment, with minimal distortion. When air-quenched from the proper hardening temperature, it can be expected to expand or contract approximately 0.0005 in./in. (0.0005 mm/mm).

- Good Toughness (Moderate/Fair): While often considered somewhat brittle compared to other steels, D2 possesses moderate or fair toughness for its class.

- High Strength and Hardness: D2 is a high-strength and hardness tool steel, with a hardness range of 60-62 HRC. It is resistant to softening.

- Cost-Effectiveness: The molybdenum and vanadium content of D2 steel is not particularly high, so it has cost advantages for users.

- Corrosion Resistance and Good Staining Resistance: It has good corrosion resistance, and its high chromium content makes D2 steel appreciable resistance to staining after tools are hardened and polished.

- Deep-Hardening: D2 is a deep-hardening steel. It can be fully hardened throughout a large block (e.g., 75 mm × 150 mm × 250 mm or 3 in. × 6 in. × 10 in.) by air cooling after austenitizing.

- Secondary Hardening: The molybdenum and vanadium in D2 steel enable secondary hardening after tempering.

5.2 Disadvantages

- Low Machinability: D2 steel is very hard and difficult to machine.

- Brittleness: D2 is considered somewhat brittle and has low toughness。

- Welding Difficulty: D2 tool steel is generally known to be difficult to weld (non-weldable). It is particularly hard to attain a high-quality welded joint by conventional welding methods due to its high carbon content and a significant amount of carbides.

- Retained Austenite: After hardening, D2 can retain a significant amount of austenite (up to 20%) that does not transform to martensite. This can lead to dimensional instability over time, as retained austenite can spontaneously transform into untempered martensite at room temperature, causing a change in the physical size of the component.

- Limited Toughness Improvement through Hardness Reduction: The toughness of D2 steel can only be improved to a limited extent, and it is difficult to control its hardness at extremely high tempering temperatures.

- Not Stainless Steel Corrosion Resistance: Its high chromium content is not sufficient to provide the level of corrosion resistance characteristic of stainless steel, as much of the chromium is incorporated into alloy carbides.

6. Welding of D2 steel

D2 steel contains a large amount of carbides, which makes it difficult to weld. If welding D2 is necessary, it is strongly recommended to preheat the D2 steel; otherwise, cracking may occur or the service life of the material may be reduced.

6.1 Preparation and Pre-heating

Before welding, remove all loose chips and grind out any cracks, preferably creating a “U”-shaped channel rather than a “V” shape, as sharp angles can induce cracking.

The preheating temperature can be adjusted between 140°C and 450°C, depending on the specific tool. For severe repairs, a preheating temperature of at least 300°C to 400°C is recommended. The preheating temperature must be reached gradually and uniformly. It is essential to ensure that the temperature during the welding process does not deviate from the preheating temperature by more than 100°C.

6.2 Filler Materials

- For general joining of broken pieces, or as a buffer layer for large repairs, 312 stainless steel filler wire (0.1% C, 1.6% Mn, 30% Cr, 9% Ni, 26 HRC, 25% elongation) is an excellent choice.

- When hardness is not the primary concern but chemical composition is, we suggest 410 stainless steel filler wire (0.1% C, 14.5% Cr, 40 HRC).

- For highly polished or photo-etched D2 tools, a modified 420 stainless steel tool steel filler wire (modified 13% chrome, 52-56 HRC) is recommended.

6.3 Post-weld Treatment

Once the D2 material is welded, it should be slow-cooled, for example, by burying it in vermiculite or dry sand. For hardened D2 parts that have been welded, stress relief and tempering treatment are required. The stress relief temperature is 400°F (205°C), followed by tempering at a temperature 25°F (14°C) lower than the original tempering temperature.

7. Machinability of D2 steel

As mentioned several times before, D2 is a high-carbon, high-chromium steel that is considered difficult to machine and grind. Its machinability is described as “particularly poor” or “low to very low.” When compared to a 1% carbon steel rated at 100, D2 has a machinability rating of 45. For comparison, O1 tool steel has excellent machinability, while D2 has better wear resistance.

Traditional machining methods include milling, drilling, or turning. After machining, the D2 surface may exhibit changes such as roughness (R), plastic deformation (PD), microcracks (MCK), untempered martensite (UTM), and overtempered martensite (OTM).

8. How do we manufacture the D2 tool steel

We primarily supply forged D2 tool steel. We procure D2 steel ingots from an Electric Arc Furnace (EAF) foundry, with the option to include Electroslag Remelting(ESR) treatment upon customer request. After verifying the composition and microstructure of the billets and ingots, we proceed with forging. Following forging into round bars or flat bars, the material undergoes heat treatment. Finally, based on customer requirements, surface treatment is performed, including the removal of scale or finishing.

9. D2 comparison with other steels

- D2 steel Vs. 440C. D2 steel has significantly lower corrosion resistance than 440C steel. In applications where D2 steel is used, corrosion resistance is not the primary consideration; instead, wear resistance and dimensional stability are the primary priorities. 440C steel is ideal when a balance of high hardness, wear resistance, and good corrosion resistance is required, making it suitable for cutting tools, surgical instruments, and bearing applications in corrosive environments.

- D2 steel Vs. 4140. D2 steel exhibits excellent wear resistance and dimensional stability, making it an ideal choice for cold-worked die steel; however, it has poor toughness and machinability. 4140 steel, on the other hand, is a more versatile engineering steel that offers a robust balance of strength and toughness, suitable for a broader range of machinery components, particularly those requiring good impact resistance and ease of processing. Its properties can be further customized through various heat treatments and surface modifications, such as nitriding.

- D2 vs D3 tool steel. Both are important representatives of the D series of steels. In terms of composition, D2 steel contains Mo and V elements, making it more expensive than D3 steel; however, its performance is also more reliable.

10. Supply forms and dimensions

The D2 tool steel we supply is available in various shapes, including round bars, sheet plates, slabs, flat bars, square bars, and blocks. The dimensions of the flat bar range from: width 20–600 mm × thickness 20–400 mm × length 1,000–5,500 mm. The dimensions of the round bar range from a diameter of 20–400 mm × a length of 1,000–5,500 mm. The block dimensions are obtained by cutting the flat bar.

For smaller sizes, such as round bars with a diameter less than 70 mm, we use the hot-rolled process. For sizes greater than 70 mm, we offer forged products.

We also offer the ESR (Electroslag Remelting) process, which is tailored to meet customer requirements. The advantage is better internal microstructure, but it comes at a higher cost. Please contact us for specific requirements.

UT testing: Sep 1921-84 D/d, E/e.

Surface Treatment: original black, peeled, machined/turned, polished, grounded, or milled surface finishes.

Inventory Status: We do not maintain a stock of D2 steel. We arrange production based on customer orders.

Delivery time: Electric Arc Furnace (EAF) materials are 30-45 days. ESR materials are approximately 60 days.

- Roberts, G., Krauss, G., & Kennedy, R. (1998). Tool Steels: 5th Edition (p. 203). ASM International. ↩︎

- Reardon, A. C. (Ed.). (2011). Metallurgy for the Non-Metallurgist (2nd ed., p. 231). ASM International. ↩︎

- Di Schino, A., & Sugimoto, K. (Eds.). (2017). Mechanical Properties and Microstructure of Forged Steel (p. 151). MDPI. ↩︎

FAQ

People sometimes dislike D2 steel for knives because of its lower toughness, which can make it prone to chipping or breaking under hard use. It is also widely considered difficult to sharpen, especially in the field without diamond stones. (Why is D2 tool steel so hard to sharpen?) Another reason for its decreased popularity is a perception problem caused by market oversaturation with cheaper knives that often feature poor or inconsistent heat treatment, leading to a bad reputation for the steel itself. Some also believe it is overpriced when used in premium knives. For more information, please read Is D2 tool steel good for knives?

No, D2 tool steel is not rust-proof, but it is moderately corrosion-resistant. It has a high chromium content, similar to stainless steel, which gives it this moderate resistance, leading it to sometimes be called “semi-stainless” steel. However, it can still rust or develop corrosion spots in wet, moist, or acidic environments if not properly cared for.

Yes, D2 tool steel is generally expensive. Its higher price is attributed to the high percentage of alloying elements included in its composition.

D2 tool steel is a type of steel specifically designed for use in tooling. It is highly regarded for its exceptional hardness, wear resistance, and abrasion resistance. Characterized as a high-carbon, high-chromium, air-hardening tool steel, the “D” in “D2” signifies its belonging to the D-series of cold-work tool steels.

High hardness (typically 62 Rockwell C).

Excellent wear resistance.

High tensile strength.

Moderate corrosion resistance.

Poor machinability.

High density.

Deep hardness. Its microstructure features numerous, large, chromium-rich alloy carbides.

D2 tool steel typically achieves a hardness of 62 Rockwell C (HRC). After proper heat treatment, its hardness can range between 55-62 HRC or 58-62 HRC. For maximum wear resistance, tempering between 149 °C and 177°C (300°F and 350°F) can result in a hardness of 62-64 HRC.

Yes, D2 tool steel is generally considered good for knives. Its high hardness and wear resistance allow it to stay sharper for longer, which is particularly beneficial for knives used in demanding tasks, such as bushcraft. It is a favorite for custom blades due to its exceptional edge retention.

While D2 tool steel can be used for bushcrafting, opinions are mixed. Some experts advise caution for field knives because of their lower toughness, which can make them prone to chipping, and their difficulty in field sharpening with limited tools, like a rock. Steels with higher toughness are generally preferred for such applications. However, some users have reported good experiences with D2 in bushcraft, noting its durability and edge retention in various weather conditions. A variant, CPM-D2, is considered better for field knives as it reduces chipping.

Yes, D2 tool steel is a suitable material for hole punching applications. It is commonly recommended for punches, along with M2 and A2 tool steels, particularly in production stamping presses. Punches made from D2 steel can achieve hundreds of thousands of hits before requiring regrinding.

D2 steel can be challenging to sharpen, especially with traditional ceramic stones, but diamond stones are highly effective due to D2’s hardness and large carbides. A lower grit edge, such as a 400-grit finish, is often recommended, as D2 typically performs well with a “toothy” edge and does not take a very fine edge as easily as other steels. Regularly honing the edge with ceramic stones or diamond paste can extend the time between full sharpenings.

D2 steel is challenging to machine because of its hardness and work hardening.

General recommendations: Machine D2 steel in its annealed state (around 25 HRC) whenever possible. Use carbide tools, especially those with PVD coatings like TiAlN, as high-speed steel (HSS) is not effective.

Turning: Cutting speeds of 100-135 m/min (330-440 SFM) and feed rates of 0.008-0.012 inches per revolution (IPR). Coolant is recommended to control heat.

Milling: Cutting speeds of 60-85 m/min (200-280 SFM) and feed rates of 0.002-0.004 inches per tooth (IPT). Use light depths of cut (0.02-0.05 inches per pass). Climb milling is recommended for cleaner edges.

Drilling: Speeds of 40-55 m/min (130-180 SFM) and feeds of 0.001-0.003 IPR, with peck drilling (0.1-0.2 inches per plunge) to clear chips and prevent bit breakage.

To prevent rust on D2 tool steel, which is moderately corrosion-resistant but not rust-proof:

Clean and dry the blade thoroughly after every use.

Apply a light coat of oil (e.g., gun oil or Ballistol) to the blade, especially if it will be exposed to damp or sweaty environments.

Avoid leaving it soaking in water or in other corrosive environments, and do not put it in a dishwasher.

Machining a polished surface finish can also enhance its corrosion resistance.

Yes, D2 tool steel can be welded, but it is difficult. Its high carbon content makes the welding process risky, as it can lead to cracking and embrittlement in the heat-affected zone (HAZ). To weld D2 steel, it must first be in the annealed condition, and it requires preheating to a temperature between 370 °C and 540 °C during the welding process.

CPM-D2 is a powder metallurgical (PM) variant of D2 steel. The PM process refines the material by reducing carbide size and creating a more uniform microstructure. This significantly improves its toughness and overall blade characteristics, leading to less chipping compared to standard ingot D2. CPM-D2 is considered to have better edge stability and is regarded by some as remarkably well-balanced, offering edge retention superior to 3V and toughness roughly double that of A2 (though some data places its toughness similar to A2).

Both D2 steel and stainless steel are recognized for their corrosion resistance due to their chromium content. However, D2 typically contains around 12% chromium, while stainless steel grades can have between 10% and 20%. This compositional difference means stainless steel generally offers better corrosion resistance, whereas D2 tool steel provides superior wear resistance and hardness properties. D2 is often referred to as “semi-stainless”.

A2 tool steel contains less chromium (around 5%) than D2 (typically 11-13%). While both steels achieve similar hardness levels (A2 at 57-62 HRC, D2 at 58-62 HRC), A2 is known for its better machinability and is generally “kinder” to tools than D2. D2, however, offers excellent wear resistance, surpassing A2 in this aspect.

Germany: 1.2379 (DIN 1.2379, EN X153CrMoV12).

Japan: SKD11 (JIS SKD11).

UK: BD2.

France: Z160CDV12.

Russia: Ch12D1.

Spain: F5211.

China: Cr12Mo1V1 or Cr12MoV

D2 and 8Cr13MoV are different categories of steel. What is 8Cr13MOV steel? 8Cr13MoV is a type of stainless steel that is far better than D2 in terms of rust resistance. However, they are both used in the manufacture of cutting tools. D2 steel has a higher hardness than 8Cr13MoV. 8Cr13MoV steel hardness is 58-60 HRC. D2 steel excels in edge retention, while 8Cr13MoV steel is more balanced across the other features, especially in ease of sharpening and corrosion resistance.

Insufficient Toughness: D2 steel has relatively low toughness, making it prone to fracturing under impact or high stress, especially in low-temperature environments.

Difficult Machinability: D2 has high hardness. It is difficult to process, requiring specialized equipment and techniques, which increases production costs.

Limited Corrosion Resistance: Although it has a high chromium content, D2 steel’s corrosion resistance is still inferior to that of stainless steel, and it may rust when exposed to humid or corrosive environments for extended periods.

Prone to Chipping: The high hardness of D2 steel makes its blades susceptible to chipping under impact, particularly in thin or fine-edged tools.

High Cost: The production and processing costs of D2 steel are relatively high, making it more expensive compared to other materials.

Complex Heat Treatment: The heat treatment process for D2 steel is intricate, requiring precise control of temperature and time; otherwise, it may lead to cracking or deformation.

Poor Weldability: D2 steel has poor welding performance, as it is prone to cracking during welding, necessitating special precautions.

Yes, D2 tool steel can be machined, but it is considered challenging, especially in its hardened state, because of its high hardness and abrasive carbide content. It is easier to machine in its annealed state.

Need High-Performance D2 Tool Steel?

Leverage Aobo Steel’s 20+ years of forging expertise. We provide top-grade D2 tool steel, ensuring exceptional durability, wear resistance, and precision for all your demanding applications. Partner with us for quality you can trust.

Ready to elevate your project? Simply fill out the form below to connect with our D2 steel specialists and receive your personalized quote!

Explore Our Other Products

D2/1.2379/SKD11

D3/1.2080/SKD1

D6/1.2436/SKD2

A2/1.23663/SKD12

O1/1.2510/SKS3

O2/1.2842

S1/1.2550

S7/1.2355

DC53

H13/1.2344/SKD61

H11/1.2343/SKD6

H21/1.2581/SKD7

L6/1.2714/SKT4

M2/1.3343/SKH51

M35/1.3243/SKH55

M42/1.3247/SKH59

P20/1.2311

P20+Ni/1.2738

420/1.2083/2Cr13

422 stainless steel

52100 bearing steel

440C stainless steel

4140/42CrMo4/SCM440

4340/34CrNiMo6/1.6582

4130

5140/42Cr4/SCR440

SCM415