Understanding the Tensile Strength of 4140 Steel

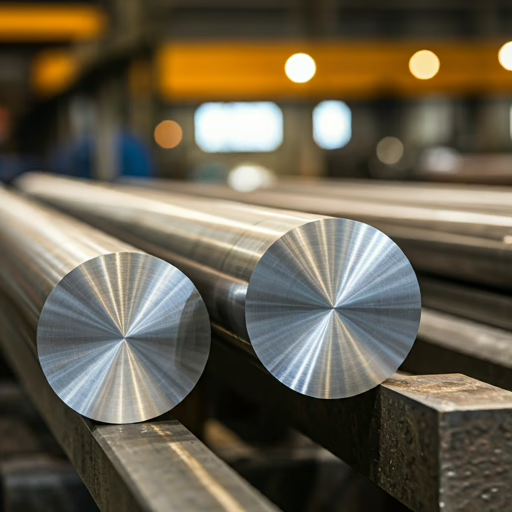

When selecting materials for demanding applications, understanding the mechanical properties is critical. For engineers working with structural components and machinery, tensile strength is a key metric. Let’s take a straightforward look at AISI 4140 steel, a popular choice we supply here at Aobo Steel, and specifically its tensile strength. What is 4140 Steel? First, AISI […]

Understanding the Tensile Strength of 4140 Steel Read More »