كتالوج الفولاذ عالي السرعة

سلسلة الفولاذ عالي السرعة

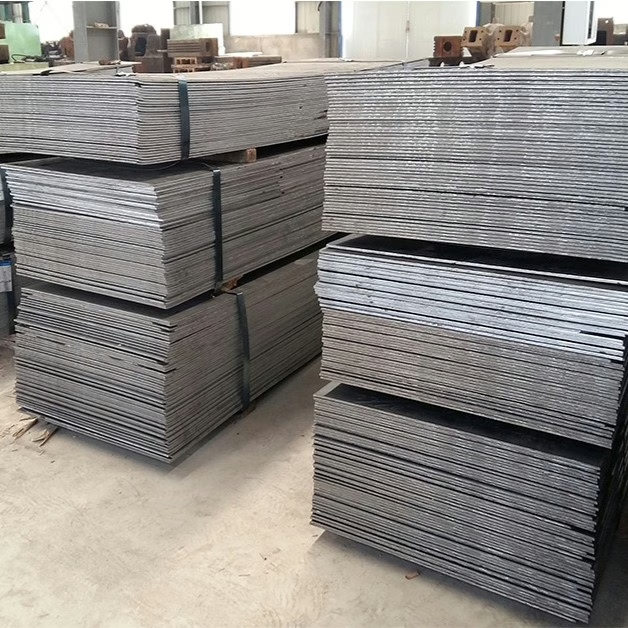

تقدم شركتنا الفولاذ عالي السرعة التالي

مقدمة عن الفولاذ عالي السرعة

الفولاذ عالي السرعة أداة متخصصة معروفة بصلابة عالية عند درجات حرارة مرتفعة، تصل عادةً إلى 595 درجة مئوية (1100 درجة فهرنهايت) (مثل 48 HRC). هذه الخاصية تجعله مناسبًا بشكل خاص لأدوات القطع المستخدمة في تشغيل المعادن بسرعة عالية، مثل المثاقب، وقواطع الطحن، وأدوات الخراطة. يُطلق عليه غالبًا اسم "الصلابة الحمراء" نظرًا لمقاومته للتليين عند درجات الحرارة العالية.

التكوين والتصنيف

الفولاذ عالي السرعة هو نظام سبائك معقد متعدد المكونات، يتكون من الموليبدينوم (Mo) والتنغستن (W) كعنصري سبائك رئيسيين، مع إضافة الكروم (Cr) والفاناديوم (V) والكوبالت (Co). يعتمد التصنيف على معايير المعهد الأمريكي للحديد والصلب (AISI)، ويُقسم إلى مجموعتين رئيسيتين:

المجموعة م (الفولاذ عالي السرعة المعتمد على الموليبدينوم): مع كون الموليبدينوم هو العنصر الرئيسي في السبائك، يتم تقسيمها إلى مجموعتين فرعيتين:

المجموعات الفرعية التي تحتوي فقط على الموليبدينوم أو كميات صغيرة من التنغستن، على سبيل المثال M1، M7، M10.

المجموعات الفرعية التي تحتوي على الموليبدينوم وكمية كبيرة من التنغستن، على سبيل المثال M2، M3، M4.

المجموعة T (الفولاذ عالي السرعة المعتمد على التنغستن): التنغستن هو العنصر الرئيسي في السبائك، على سبيل المثال T1، T2، T4، T5، T6، T8، T15.

تتشابه درجات الفولاذ النموذجية في المجموعتين M وT (مثل M1، M2، T1) بشكل كبير من حيث الخواص وأداء القطع، ويمكن استخدامها بالتبادل في العديد من التطبيقات. بالإضافة إلى ذلك، يمكن معالجة بعض الأنواع عالية السبائك (مثل التعديلات المحتوية على الكوبالت) للحصول على صلابة فائقة (69-70 HRC).

الخصائص الرئيسية

تنبع الخصائص الفريدة لـ HSS من تركيب السبائك ومعالجتها وتتضمن الميزات الرئيسية التالية:

- صلابة درجات الحرارة العالية ومقاومة التآكل: بفضل وجود كربيدات السبائك مثل كربيدات M₆C و MC، تحافظ HSS على صلابتها (63-70 HRC) في درجات الحرارة العالية، مع تصنيفات مقاومة التآكل 7-9.

- المتانة: اعتمادًا على درجة الفولاذ المحددة، تتراوح تصنيفات المتانة من 3 إلى 8. يمكن للفولاذ أن يتحمل بعض الصدمات والإجهاد الميكانيكي.

- خصائص المعالجة: أ. التصلب عند درجات حرارة مرتفعة قريبة من نقطة الانصهار. ب. حجم حبيبات أوستنيتي دقيق. ج. تصلب عميق بالتبريد الهوائي الساكن. د. تأثير تصلب ثانوي ملحوظ أثناء التطبيع.

معلومات المنتج الأساسية

إيسي M2/DIN 1.3343/JIS SKH51

التركيب الكيميائي

| العنصر | الكربون (C) | الكروم (Cr) | الموليبدينوم (Mo) | الفاناديوم (V) | التنجستن (W) | السيليكون (Si) | المنجنيز (Mn) | الفوسفور (P) | الكبريت (S) |

| فولاذ M2 (AISI) | 0.78 – 0.88% | 3.75 – 4.50% | 4.50 – 5.50% | 1.75 – 2.20% | 5.50 – 6.75% | 0.20 – 0.45% | 0.15 – 0.40% | ≤0.03% | ≤0.03% |

| فولاذ 1.3343 (DIN) | 0.86 – 0.94% | 3.80 – 4.50% | 4.70 – 5.20% | 1.70 – 2.10% | 5.90 – 6.70% | ≤0.45% | ≤0.40% | ≤0.030% | ≤0.030% |

| فولاذ SKH51 (JIS) | 0.80 – 0.88% | 3.80 – 4.50% | 4.70 – 5.20% | 1.70 – 2.10% | 5.90 – 6.70% | ≤0.45% | ≤0.40% | ≤0.030% | ≤0.030% |

صفات

فولاذ M2 أداة عالية السرعة تتميز بمقاومة ممتازة للتآكل، وصلابة حمراء عالية، ومتانة عالية. وهو مثالي لأدوات القطع المستخدمة في السرعات ودرجات الحرارة العالية.

التطبيقات

المثاقب/قواطع الطحن/الصنابير/شفرات المنشار/أدوات النجارة (الأزاميل، والمقاشط، ورؤوس التوجيه)/أدوات العمل الباردة (اللكمات، والقوالب)/المشابك/المثاقب/أدوات القطع بالتروس (المواقد)

ايسي M35/دين 1.3243/جيس SKH55

التركيب الكيميائي

| العنصر | الكربون (C) | الكروم (Cr) | الموليبدينوم (Mo) | الفاناديوم (V) | التنجستن (W) | الكوبالت (Co) | السيليكون (Si) | المنجنيز (Mn) | الفوسفور (P) | الكبريت (S) |

| فولاذ AISI M35 | 0.87 – 0.95% | 3.80 – 4.50% | 4.70 – 5.20% | 1.70 – 2.10% | 5.90 – 6.70% | 4.50 – 5.00% | ≤0.45% | ≤0.40% | ≤0.030% | ≤0.030% |

| فولاذ DIN 1.3243 | 0.87 – 0.95% | 3.80 – 4.50% | 4.70 – 5.20% | 1.70 – 2.10% | 5.90 – 6.70% | 4.50 – 5.00% | ≤0.45% | ≤0.40% | ≤0.030% | ≤0.030% |

| فولاذ JIS SKH55 | 0.87 – 0.95% | 3.80 – 4.50% | 4.70 – 5.20% | 1.70 – 2.10% | 5.90 – 6.70% | 4.50 – 5.00% | ≤0.45% | ≤0.40% | ≤0.030% | ≤0.030% |

صفات

فولاذ M35 هو فولاذ أداة عالي السرعة معروف بصلابته الحمراء الاستثنائية ومقاومته الفائقة للتآكل وصلابته العالية ومتانته الجيدة وخصائصه المحسنة بسبب إضافة الكوبالت.

التطبيقات

المثاقب/قواطع الطحن/الصنابير/شفرات المنشار/البراغي/المثاقب/المواقد/الأزاميل/المقاشط/بتات التوجيه/قوالب الختم الدقيقة/قوالب لف الخيوط/قوالب القطع/الثقوب/شفرات القص

إيسي M42/DIN 1.3247/JIS SKH59

التركيب الكيميائي

| العنصر | الكربون (C) | الكروم (Cr) | الموليبدينوم (Mo) | الفاناديوم (V) | التنجستن (W) | الكوبالت (Co) | السيليكون (Si) | المنجنيز (Mn) | الفوسفور (P) | الكبريت (S) |

| فولاذ AISI M42 | 1.08% | 3.90% | 9.40% | 1.20% | 1.50% | 8.00% | 0.25% | 0.25% | غير متوفر | غير متوفر |

| فولاذ DIN 1.3247 | 1.05 – 1.15% | 3.50 – 4.50% | 9.00 – 10.0% | 0.90 – 1.30% | 1.20 – 1.90% | 7.50 – 8.50% | ≤0.70% | ≤0.40% | ≤0.030% | ≤0.030% |

| فولاذ JIS SKH59 | 1.05 – 1.15% | 3.50 – 4.50% | 9.00 – 10.00% | 0.90 – 1.30% | 1.20 – 1.90% | 7.50 – 8.50% | ≤0.70% | ≤0.40% | ≤0.030% | ≤0.030% |

صفات

الفولاذ M42 هو فولاذ أداة عالي السرعة معروف بصلابته الحمراء الاستثنائية ومقاومته الفائقة للتآكل وصلابته العالية بسبب محتواه العالي من الكوبالت.

التطبيقات

المثاقب عالية السرعة/قواطع النهايات/الصنابير/البراغي/شفرات المنشار/قواطع الطحن/المثاقب/أدوات القطع بالتروس/أدوات النجارة للمواد الكاشطة

مزايا Aobo Steel

- مع ضمان الجودة، أسعارنا أقل بحوالي 3% من سعر السوق.

- قبل الشحن، تخضع جميع بضائعنا لاختبارات صارمة للمكونات 100%، واختبار UT، واختبار الصلابة.

- إن خبرتنا الممتدة لأكثر من 20 عامًا في إنتاج الفولاذ المزور تمنحنا فهمًا عميقًا لمنتجاتنا.

- نحن نقدم أكثر من 100 نوع من الفولاذ، بما في ذلك الفولاذ الفولاذي، والفولاذ السبائكي، والفولاذ المقاوم للصدأ، والفولاذ الهيكلي السبائكي، والفولاذ الكربوني.

- بفضل وجود أكثر من 40 موردًا للمعالجة، يمكننا تسليم أكثر من 2000 طن من الفولاذ شهريًا.