5CrNiMo steel is a traditional low-alloy hot-work tool steel that has been widely used in various applications, particularly for forging dies. It has excellent hardenability, good toughness, and moderate strength at elevated temperatures, though it has some limitations in very high-temperature or high-wear applications. 5CrNiMo is a grade under China’s GB/T standard, with equivalent grades including American AISI L6, Japanese JIS SKT4, and German DIN W-Nr. 1.2713 and 1.2714.

1. Chemical Composition of 5CrNiMo Steel(GB / T 1299—2000)

| C | Si | Mn | Kr | Ni | Mo | P | S |

| 0.50-0.60 | ≤0,40 | 0.50-0.80 | 0.50-0.80 | 1.40-1.80 | 0.15-0.30 | ≤0,030 | ≤0,030 |

2. Physical Properties of 5CrNiMo

2.1 Critical Temperature of 5CrNiMo

| Punkt krytyczny | Ac1 | Ac3 | Ar1 | Ar3 | SM |

| Temperature/ °C | 730 | 780 | 610 | 640 | 230 |

2.2 Linear Expansion Coefficient of 5CrNiMo

| Temperatura / °C | 100 ~ 250 | 250 ~ 300 | 350 ~ 600 | 600 ~ 700 |

| Linear Expansion Coefficient α / x10⁻⁶ °C⁻¹ | 12.55 | 14.1 | 14.2 | 15.0 |

2.3 Elastic Modulus of 5CrNiMo

| Temperatura / °C | Room Temp | 100 | 200 | 300 | 400 | 500 |

| E / MPa | 209 720 | 206 780 | 203 840 | 198 940 | 193 060 | 186 200 |

2.4 Shear Modulus of 5CrNiMo

| Temperatura / °C | Room Temp | 100 | 200 | 300 | 400 | 500 |

| G / MPa | 83 300 | 82 320 | 80 360 | 78 400 | 75 460 | 73 500 |

2.5 Thermal Conductivity

| Temperatura / °C | Room Temp | 100 | 200 | 300 | 400 | 500 |

| λ / [W / (m · K)] | 0.44 | 0.44 | 0.43 | 0.43 | 0.39 | 0.35 |

2.6 Specific Heat Capacity

| Temperatura / °C | Room Temp ~ 100 | Room Temp ~ 200 | Room Temp ~ 300 | Room Temp ~ 400 | Room Temp ~ 500 |

| cₚ (20°C) / [J / (kg · K)] | 0.484 | 0.497 | 0.509 | 0.531 | 0.552 |

2.7 Density is 7.804 g/cm³.

3. Hot Forging Process Specification of 5CrNiMo

| Przedmiot | Temperatura ogrzewania / °C | Początkowa temperatura kucia / °C | Końcowa temperatura kucia / °C | Metoda chłodzenia |

| Sztabka stali | 1140 ~ 1180 | 1100 ~ 1150 | 800 ~ 880 | Powolne chłodzenie (chłodzenie w dołku lub piasku) |

| Kęsy stalowe | 1100 ~ 1150 | 1050 ~ 1100 | 800 ~ 850 | Powolne chłodzenie (chłodzenie w dołku lub piasku) |

Notatka: 5CrNiMo steel can be hardened by cooling in air, but it is prone to forming white spots, so it should be cooled slowly after forging. For large forgings, they must be held in a furnace at 600°C until the temperature is uniform, then slowly cooled to 150-200°C, and finally cooled in air. For larger forgings, tempering should be carried out immediately after cooling to 150-200°C.

Please complete the following contact form to receive the most accurate quotation for 5CrNiMo steel.

4. Heat Treatment of 5CrNiMo

4.1 Podgrzewanie wstępne

① Post-Forging Annealing Options

| Preliminary Heat Treatment Option | Parametry procesu |

| Wyżarzanie po kuciu | Heat to 760–780°C, hold for 4–6 hours, then cool the furnace to below 500°C before unloading for air cooling. After annealing, the hardness ranges from 197 to 241 HBW, with a microstructure of pearlite + ferrite. |

| Wyżarzanie izotermiczne po kuciu | Heating temperature: 850–870°C, held for 4–6 hours; Isothermal temperature: 680°C, held for 4–6 hours; Cooled in the furnace to below 500°C, then removed for air cooling; Post-annealing hardness: 197–241 HBW; Microstructure: pearlite + ferrite. |

| Forging Die Renewal Annealing | Heat to 710–730°C, hold for 4–6 hours, then cool in the furnace to below 500°C before removing for air cooling. Post-annealing hardness: 197–241 HBW. |

② Microstructure and Hardness Before and After Annealing

| Średnica wcięcia / mm | HBW | Mikrostruktura (przed wyżarzaniem) | Mikrostruktura (po wyżarzaniu) |

| 3.9 ~ 4.3 | 241 ~ 197 | Troostyt + Martenzyt | Pearlite + Ferrite |

4.2 Hartowanie

① Recommended Quenching Process Specification

| Temperatura hartowania/°C | Środek chłodzący do hartowania | Temperatura czynnika chłodzącego hartującego/°C | Continued | Twardość HRC |

| 830 ~ 860 | Olej | 20 ~ 60 | Temper immediately after cooling to 150 ~ 180°C | 53 ~ 58 |

Notatka:

- For large molds, use the upper limit for quenching heating temperature; for small molds (side length below 200–300 mm), use the lower limit.

- To minimize stress and deformation during quenching, after heating to 830–860°C, first pre-cool in air to 750–780°C, then oil-quench to 150–180°C. Remove and immediately temper.

- For large molds, slowly heat to 600–650°C and hold for 1–1.5 hours. Only increase furnace temperature after thorough heating. To improve heating quality, place workpieces on 60–100mm thick backing plates during heating.

- Module quenching at low oil immersion temperatures increases cracking risk. To prevent cracking, actual practice often involves oil immersion around 200°C. While this produces a martensitic surface layer, the core remains in the austenitic state. To extend service life, isothermal quenching can be employed.

② Isothermal Quenching Process

| Process Type | Quenching Temp. (°C) | Medium chłodzące | Medium Temp. (°C) | Isothermal Temp. & Time | Quenching Hardness (HRC) | Microstructure after Quenching |

| Isothermal Quenching | 830 – 860 | Olej | 20 – 60 | Cool mold surface to 150-200°C, then hold in a 280-300°C bath for 2-3h | – | Small amount of bainite + lower bainite + retained austenite. After tempering, bainite transforms to lower bainite. |

| High-Temp Quenching | 890 – 910 | Olej | – | – | 61.5 | Lath martensite + retained austenite (approx. 9.2% by volume), grain size 7-8. |

Uwagi:

- Isothermal Quenching: This process reduces the tendency for the mold to crack and improves its service life.

- High-Temperature Quenching: Tempering temperature is 420-550°C, tempered twice, resulting in a hardness of 38-47 HRC.

4.3 Hartowanie

① Zalecane specyfikacje procesu hartowania

| Plan | Cel hartowania | Forging Die Specification | Temperatura odpuszczania (°C) | Sprzęt grzewczy | Twardość (HRC) |

| I | Eliminate stress, stabilize structure and size | Small | 490 ~ 510 | Gas furnace or Electric furnace | 44 ~ 47 |

| Średni | 520 ~ 540 | 38 ~ 42 | |||

| Large | 560 ~ 580 | 34 ~ 37 | |||

| II | Dovetail (Medium) | 620 ~ 640 | 34 ~ 37 | ||

| Dovetail (Small) | 640 ~ 660 | 30 ~ 35 |

Notatka: After tempering, oil quenching should be performed to prevent the development of temper brittleness. To relieve stresses generated during oil quenching, a second tempering at 160–180°C may be conducted. Large forging dies must not be cooled to room temperature in oil during either quenching or tempering, as this may cause cracking.

② Effect of Quenching and Tempering Temperatures on Impact Toughness

| Tempering Temp. (°C) | 300 | 350 | 400 | 450 | 500 | |

| Quenching Temp. (°C)840 | The values in the table represent impact toughness, a_k / (J/cm²). | 21 | 25 | 29 | 35 | 45 |

| Quenching Temp. (°C)950 | 19 | 20 | 23 | 25 | 35 | |

| Quenching Temp. (°C)1000 | 13 | 16 | 20 | 23 | 30 |

Notatka: When the 5CrNiMo steel module is tempered at 380-450°C, the supercooled austenite in the core transforms into an upper bainite structure, resulting in extremely poor impact toughness.

③ Effect of Quenching and Tempering Temperatures on Hardness of 5CrNiMo

| Tempering Temp. (°C) | 300 | 350 | 400 | 450 | 500 | 550 | 600 | |

| Quenching Temp. (°C)850 | Twardość HRC | 52 | 50 | 48 | 45 | 41 | 38 | 32 |

| Quenching Temp. (°C)900 | 52 | 50 | 48 | 45 | 41 | 38 | 32 | |

| Quenching Temp. (°C)950 | 53 | 51 | 49 | 46 | 42 | 39 | 33 | |

| Quenching Temp. (°C)1000 | 54 | 52 | 50 | 47 | 43 | 40 | 34 |

5. Właściwości mechaniczne

5CrNiMo steel is a traditional hot-forging die steel, exhibiting good plasticity and toughness alongside adequate strength and wear resistance. It is insensitive to size effects, with room-temperature mechanical properties nearly identical to those at temperatures ranging from 500 to 600°C. When heated to 500°C, it still maintains a hardness of approximately 300 HBW. Due to its low content of carbide-forming elements, the secondary hardening effect is weak, resulting in poor thermal stability and low high-temperature strength.

5.1 High-Temperature Hardness of 5CrNiMo

| Temperatura (°C) | 300 | 450 | 600 | 650 | 710 | 750 |

| Hardness (HV) | 383 | 351 ~ 354 | 254 ~ 274 | 201 ~ 203 | 147 ~ 154 | 71.3 ~ 72.7 |

5.2 High-Temperature Impact Toughness of 5CrNiMo

| Temperatura (°C) | 300 | 600 | 650 | 700 |

| Impact Absorption Energy (KU/J) | 48.4 | 36.4 | 36.3 | 70.3 |

5.3 Thermal Fatigue Performance

| Test Method & State | 20°C ←→ 650°C (1000 cycles) | 20°C ←→ 750°C (1000 cycles) |

| Level¹ | 13.4 | 20.0 |

¹The higher the level, the worse the thermal fatigue performance.

5.4 Thermal Wear Performance

| Number of Revolutions | 300 | 600 | 900 | 1200 | 1500 | 2500 |

| Weight Loss / mg | 1.00 | 2.43 | 3.27 | 4.2 | 4.97 | 5.97 |

Notatka: Using the S. R. Tittagala method, at a temperature of 800 ~ 850°C and a pressure of 784~850N.

5.5 Surface mechanical properties and core mechanical properties

| Part | Location | RM/ MPa(Tensile Strength) | Rel/ MPa(Yield Strength) | A (%)(Elongation) | Z (%)(Reduction of Area) | KU/J(Impact Energy) |

| Room Temp | Surface | 1310 | – | – | 41 | 31.3 |

| Room Temp | Core | 1020 | 761 | 16 | 42 | 14.1 |

| 300°C | Surface | 1214 | – | – | 58 | 48.4 |

| 300°C | Core | 1011 | 833 | 26 | 62 | 59.2 |

Notatka: During quenching of large-section workpieces, differing cooling rates between the surface layer and the core result in distinct mechanical properties. This phenomenon in steel is termed the mass effect, also known as the size effect.

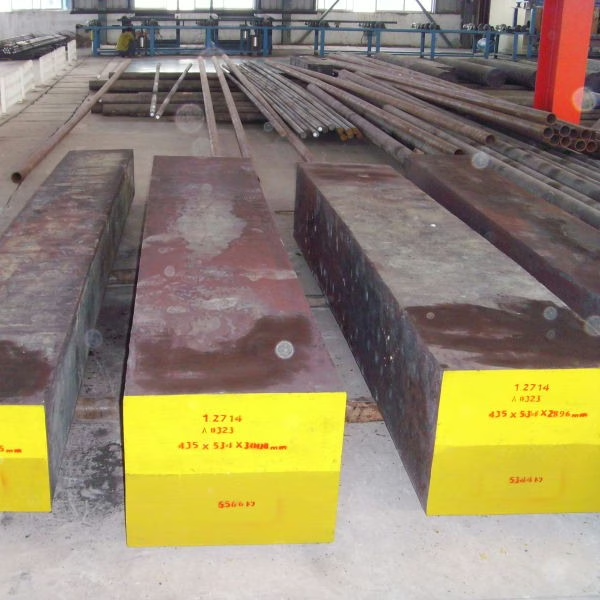

6. Zastosowania

5CrNiMo steel, due to its excellent hardenability, exhibits nearly uniform hardness across its cross-section when large blocks (300mm × 400mm × 300mm) undergo quenching in oil at 820°C followed by tempering at 560°C. Primarily used for manufacturing various small and medium-sized forging dies with side lengths ≤300mm and operating temperatures below 500°C. It is more suitable for producing large and medium-sized modules in mass production, and can also be used to fabricate complex-shaped casting mold components.

Get a Competitive Quote for 5CrNiMo Tool Steel

With over 20 years of forging expertise, Aobo Steel is your trusted partner for high-performance 5CrNiMo tool steel. We provide not just materials, but solutions. Leverage our deep industry knowledge and reliable supply chain for your project’s success.

✉ Skontaktuj się z nami wypełniając poniższy formularz.