4Cr5MoSiV Stal narzędziowa do pracy na gorąco

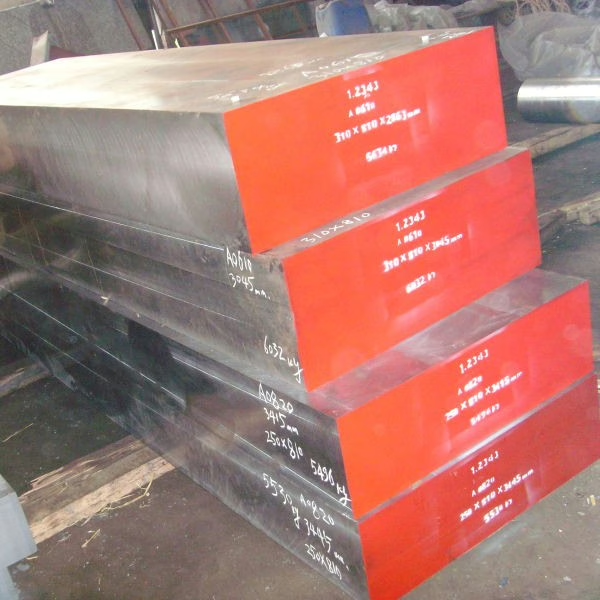

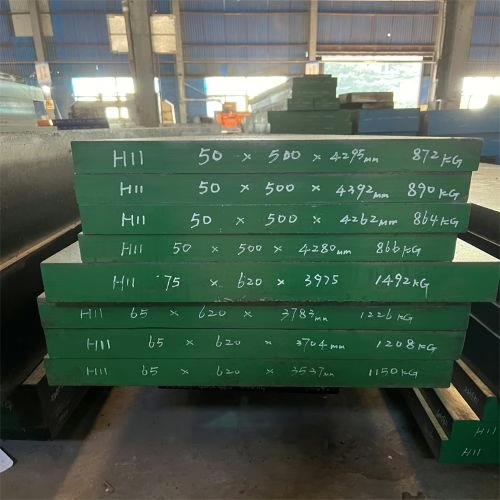

AOBO STEEL – Zaufany globalny dostawca stali narzędziowej

4Cr5MoSiV to chiński gatunek standardowy, równoważny AISI H11 w Stanach Zjednoczonych. W porównaniu z 4Cr5MoSiV1(AISI H13/DIN 1.2343) zawartość wanadu w składzie 4Cr5MoSiV jest niższa. 4Cr5MoSiV1 charakteryzuje się na ogół większą wytrzymałością na gorąco i twardością, a także jest szerzej stosowany, ale 4Cr5MoSiV jest nadal preferowany do matryc do kucia młotkowego z dużą prędkością ze względu na doskonałą odporność na zmęczenie cieplne.

1. Skład chemiczny (GB / T 1299—2000)

| C | Si | Mn | Kr | Mo | V | P | S |

| 0.33 – 0.43% | 0.80 – 1.20% | 0.20 – 0.50% | 4.75 – 5.50% | 1.10 – 1.60% | 0.30 – 0.60% | ≤0,030% | ≤0,030% |

2. Właściwości fizyczne 4Cr5MoSiV

2.1 Temperatury krytyczne

| Punkt krytyczny | Ac₁ | Ac₃ | Ar₁ | Ar₃ | SM | Mf |

| Temperatura (w przybliżeniu) / °C | 853 | 912 | 720 | 773 | 310 | 103 |

2.2 Współczynnik rozszerzalności liniowej

| Temperatura / °C | 20 ~ 100 | 20 ~ 200 | 20 ~ 300 | 20 ~ 400 | 20 ~ 500 | 20 ~ 600 | 20 ~ 700 |

| Współczynnik rozszerzalności liniowej α / 10⁻⁶ °C⁻¹ | 10.0 | 10.9 | 11.4 | 12.2 | 12.8 | 13.3 | 13.6 |

2.3 Przewodność cieplna

| Temperatura / °C | 100 | 200 | 300 | 400 | 500 | 600 | 700 |

| Przewodność cieplna λ / [W/(m·K)] | 25.9 | 27.6 | 28.4 | 28.0 | 27.6 | 26.7 | 25.9 |

2.4 Moduł sprężystości

| Temperatura / °C | 20 | 100 | 200 | 300 | 400 | 500 |

| Moduł sprężystości E/MPa | 227,000 | 221,000 | 216,000 | 208,000 | 200,000 | 192,000 |

2.5 Gęstość i ciepło właściwe

| Gęstość / (g/cm³) | Ciepło właściwe cₚ (20°C) / [J/(kg·K)] |

| 7.69 | 459.8 |

3. Gorąco Specyfikacja procesu kucia stali 4Cr5MoSiV

| Przedmiot | Temperatura ogrzewania / °C | Temperatura początkowego kucia / °C | Temperatura końcowego kucia / °C | Metoda chłodzenia |

| Sztabka stali | 1140 ~ 1180 | 1100 ~ 1150 | ≥900 | Chłodzenie piaskowe lub chłodzenie wgłębne |

| Kęsy stalowe | 1120 ~ 1150 | 1070 ~ 1100 | 850 ~ 900 | Chłodzenie piaskowe lub chłodzenie wgłębne |

Wypełnij poniższy formularz kontaktowy, aby otrzymać najnowszą ofertę 4Cr5MoSiV.

4. Obróbka cieplna 4Cr5MoSiV

4.1 Podgrzewanie wstępne

| Wstępny plan obróbki cieplnej | Parametry procesu |

| Wyżarzanie po kuciu | Temperatura nagrzewania 860–890°C, utrzymywanie przez 2–4 godz.; schłodzić w piecu do temperatury poniżej 500°C, a następnie schłodzić na powietrzu. Twardość po wyżarzaniu ≤229HBW. |

| Wyżarzanie odprężające | Temperatura grzania 730 ~ 760°C, utrzymywanie przez 3 ~ 4 godziny, chłodzenie piecem lub chłodzenie powietrzem. |

4.2 Hartowanie

① Zalecana specyfikacja procesu hartowania

| Temperatura hartowania / °C | Medium hartujące | Temperatura medium hartowniczego / °C | Następny krok | Twardość HRC |

| 1000 ~ 1030 | Olej lub powietrze | 20 ~ 60 | Schłodzić do temperatury oleju | 53 ~ 55 |

② Związek między temperaturą hartowania a twardością

| Temperatura hartowania / °C | 950 | 975 | 1000 | 1025 | 1050 | 1075 | 1100 |

| Twardość HRC | 51 | 53 | 54.5 | 56 | 58 | 58.5 | 57.5 |

4.3 Hartowanie

① Zalecana specyfikacja procesu hartowania

| Cel hartowania | Temperatura / °C | Sprzęt | Chłodzenie | Liczba temperamentów | Twardość HRC |

|---|---|---|---|---|---|

| Wyeliminuj naprężenia i zmniejsz twardość | 530 ~ 580 | Piec z kąpielą solną lub piec powietrzny | Chłodzenie powietrzem | 2 | 47 ~ 49 |

Uwaga: Druga temperatura hartowania jest zwykle niższa o 20–30°C od pierwszej.

② Właściwości mechaniczne po odpuszczaniu w różnych temperaturach

| Temperatura odpuszczania / °C | 500 | 550 | 600 | 650 |

|---|---|---|---|---|

| Twardość HRC | 57 | 54.5 | 46.5 | 37 |

| aᴋ / (J/cm²) | 20 | 45 | 60 | 66 |

Uwaga: 1000°C chłodzenie powietrzem, 580°C temperowanie.

4.4 Zalecana specyfikacja procesu wzmacniania powierzchni

| Proces | Temperatura / °C | Czas / godz. | Średni | Grubość warstwy / mm | Twardość powierzchniowa HV |

|---|---|---|---|---|---|

| Azotowanie | 560 | 2 | KNO₃ 50% + NaNO₃ 50% (ułamek masowy) | 0.04 | 640 ~ 690 |

| Azotowanie | 580 | 8 | Gaz ziemny + amoniak | 0.25 ~ 0.30 | 830 ~ 860 |

| Azotowanie | 540 | 12 ~ 20 | Szybkość rozkładu amoniaku 30% ~ 60% | 0.15 ~ 0.20 | 550 ~ 750 |

5. Właściwości mechaniczne

Stal 4Cr5MoSiV (H11) to hartowana na powietrzu stal narzędziowa do pracy na gorąco. Charakteryzuje się dobrą ciągliwością, a po wzmocnieniu cieplnym jej wytrzymałość może sięgać ponad 2070 MPa. Dzięki możliwości hartowania w powietrzu, odkształcenia hartownicze i naprężenia szczątkowe są niewielkie, a tendencja do utleniania powierzchni jest również niewielka. Stal może ulegać wtórnemu hartowaniu i osiągać optymalne parametry po odpuszczeniu w temperaturze powyżej 510°C. Po odpuszczeniu w wysokiej temperaturze można wyeliminować większość naprężeń wewnętrznych. Stal charakteryzuje się dobrą stabilnością termiczną i jest odporna na erozję stopu aluminium. W temperaturze poniżej 650°C charakteryzuje się wysoką ciągliwością, udarnością, odpornością na utlenianie, odpornością na zmęczenie cieplne, a także wysoką wytrzymałością na pełzanie i rozciąganie.

5.1 Właściwości mechaniczne w wysokich temperaturach

| Temperatura testu / °C | Rₘ / MPa | Rₑₗ / MPa | A (%) | Z (%) |

| 300 | 1504 | 1311 | 12.0 | 39.1 |

| 600 | 895 | 794 | 21.9 | 72.9 |

| 650 | 471 | 402 | 33.1 | 85.5 |

| 700 | 226 | 179 | 55.0 | 94.5 |

5.2 Twardość w wysokiej temperaturze

| Temperatura testu / °C | 300 | 450 | 600 | 650 | 700 | 750 |

|---|---|---|---|---|---|---|

| Twardość HV | 491.5 | 448.5 | 384.0 | 302.5 | 227.5 | 178.5 |

Uwaga: Oryginalna twardość próbki wynosiła 49~50HRC.

5.3 Wytrzymałość na uderzenia w wysokiej temperaturze

| Temperatura testu / °C | 300 | 600 | 650 | 700 |

|---|---|---|---|---|

| Energia absorpcji uderzenia K/J | 28.8 | 31.0 | 36.5 | 70.0 |

5.4 Wydajność zmęczenia cieplnego

| Stopień | |

|---|---|

| 20 ~ 650°C powtórzone 1000 razy | 8.2 |

| 20 ~ 750°C powtórzone 1000 razy | 14.6 |

5.5 Odporność na zużycie termiczne

Odporność stali 4Cr5MoSiV na zużycie termiczne (I)

| Obroty/czasy | 300 | 600 | 900 | 1200 | 1500 | 2500 |

|---|---|---|---|---|---|---|

| Utrata masy ciała / mg | 0.67 | 0.80 | 1.4 | 1.63 | 1.97 | 2.62 |

Uwaga: Temperatura badania 800 ~ 850°C, ciśnienie 784 ~ 882N, twardość próbki 49 ~ 50HRC.

Tabela 5-89 Odporność stali 4Cr5MoSiV na zużycie cieplne (II)

| Obroty/czasy | 100 | 200 | 300 | 400 | 500 | 600 | 700 | 1000 |

|---|---|---|---|---|---|---|---|---|

| Utrata masy ciała / mg | 0.77 | 1.67 | 2.50 | 3.47 | 4.33 | 4.90 | 5.60 | 7.40 |

Uwaga: Temperatura badania 910 ~ 950°C, ciśnienie 1784 ~ 1813N, twardość próbki 49 ~ 50HRC.

5.6 Odporność na odpuszczanie

| Temperatura / °C | 500 (temperatura szczytowa utwardzania wtórnego) | 560 | 615 | 600 | 653 |

|---|---|---|---|---|---|

| Twardość HRC | 55,0 (najwyższa twardość wtórna) | 49.0 | 42.0 | 36.0 | 35.0 |

Uwaga: Próbka hartowana w oleju w temperaturze 1020°C, twardość 59~60HRC.

5.7 Odporność na korozję cieplną

| Temperatura i czas testu | 620°C × 4 godz. | 680°C × 4 godz. |

|---|---|---|

| Utrata masy ciała / (g/dm²) | 4.4188 | 16.4 |

5.8) Granica zmęczenia

| Temperatura testu / °C | Temperatura pokojowa | 300 | 400 | 450 | 500 |

|---|---|---|---|---|---|

| σ-1 / MPa | 880 | 680 | 640 | 630 | 610 |

| σ-1 tys. / MPa | 570 | 440 | 430 | — | 420 |

5.9 Stabilność termiczna stali 4Cr5MoSiV w temperaturze 620°C

| Czas trzymania / h | 2 | 4 | 6 | 8 | 11.5 | 14.5 | 17.5 | 21 |

|---|---|---|---|---|---|---|---|---|

| Twardość HRC | 39.4 | 38.4 | 36.9 | 35.1 | 34.4 | 33.2 | 32.6 | 32.3 |

Uwaga: Oryginalna twardość próbki wynosiła 49,9 HRC.

6. Zastosowania

Stal 4Cr5MoSiV (H11) jest powszechnie stosowana do produkcji form odlewniczych do odlewów aluminiowych, matryc do wytłaczania na gorąco, narzędzi i prętów rdzeniowych do przebijania, matryc do kucia prasowego, form do tworzyw sztucznych itp. Ponadto, ze względu na dobrą wytrzymałość w średnich temperaturach, jest również stosowana do produkcji elementów konstrukcyjnych samolotów, rakiet oraz części turbin parowych i gazowych.

Uzyskaj konkurencyjną ofertę na stal narzędziową 4Cr5MoSiV

Z ponad 20-letnim doświadczeniem w kuciu, Aobo Steel jest Twoim zaufanym partnerem w zakresie wysokowydajnej stali narzędziowej 4Cr5MoSiV. Dostarczamy nie tylko materiały, ale i rozwiązania. Wykorzystaj naszą dogłębną wiedzę branżową i niezawodny łańcuch dostaw, aby Twój projekt odniósł sukces.

✉ Skontaktuj się z nami wypełniając poniższy formularz.