Co to jest 420 stal nierdzewnaStal nierdzewna 420 to znakomita stal nierdzewna martenzytyczna, ceniona za swoją hartowność i często klasyfikowana jako stal narzędziowa nierdzewna. Wykazuje właściwości ferromagnetyczne. Proces obróbki cieplnej stali nierdzewnej 420 zazwyczaj przebiega podobnie jak w przypadku stali węglowej: austenityzacja, hartowanie i odpuszczanie.

Austenityzowanie

Głównym celem austenityzacji jest podgrzanie stali do temperatury, w której cała jej struktura krystaliczna przekształca się w jednorodną fazę austenityczną, umożliwiając równomierne rozpuszczenie węgla i pierwiastków stopowych. Temperatura austenityzacji stali nierdzewnej 420 wynosi od 954°C do 1010°C (od 1750°F do 1850°F). Czas wygrzewania wynosi 30 minut na cal (lub około 1,2 minuty na milimetr) grubości.

Gaszenie

Gaszenie polega na szybkim schłodzeniu stali austenitycznej w celu wywołania przemiany austenit w martenzyt, przesyconą fazę tetragonalną o strukturze ciała centrowanego (BCT), która nadaje stali dużą twardość. Stal nierdzewna 420 charakteryzuje się wysoką hartownością i można ją skutecznie hartować przy użyciu oleju lub powietrza.

W przypadku części o złożonej lub nieregularnej geometrii, hartowanie w powietrzu jest często preferowaną metodą. Metoda ta pomaga zminimalizować odkształcenia i zmniejszyć ryzyko pęknięć. Jeśli konstrukcja elementu na to pozwala i wymagana jest maksymalna twardość, można zastosować hartowanie w oleju. Ponadto, hartowanie w oleju zazwyczaj zapewnia optymalną ciągliwość i odporność na korozję.

W przypadku hartowania w powietrzu zalecamy schłodzenie stali nierdzewnej 420 do temperatury 66°C (150°F). W przypadku hartowania w oleju typowy zakres temperatur wynosi 66–93°C (150–200°F). Po schłodzeniu do powyższej temperatury należy natychmiast przeprowadzić odpuszczanie. Opóźnienie odpuszczania może prowadzić do wzrostu naprężeń wewnętrznych i potencjalnych pęknięć.

Odpuszczanie

Odpuszczanie Proces ponownego nagrzewania zahartowanej stali do temperatury poniżej jej krytycznej temperatury transformacji (Ac1) w celu zmniejszenia kruchości i wysokiej twardości martenzytu, a tym samym poprawy wytrzymałości i udarności oraz eliminacji naprężeń wewnętrznych. Struktura martenzytyczna poddana odpowiedniemu odpuszczaniu charakteryzuje się równowagą między wytrzymałością na rozciąganie a udarnością.

Stal nierdzewna 420 musi zostać poddana dwukrotnemu, a nawet trzykrotnemu hartowaniu. Stal nierdzewna 420 musi zostać poddana dwukrotnemu, a nawet trzykrotnemu hartowaniu.

Konkretną temperaturę odpuszczania można wybrać na podstawie docelowego poziomu twardości: na przykład 150°C (300°F) pozwala uzyskać minimalną twardość 52 HRC, 204°C (400°F) pozwala uzyskać 50 HRC, a 315°C (600°F) pozwala uzyskać 48 HRC.

Każdy cykl odpuszczania wymaga określonego czasu wygrzewania, zazwyczaj 2 godzin na cal (lub około 4,7 minuty na milimetr) grubości materiału. Zalecamy chłodzenie elementów na powietrzu do temperatury pokojowej pomiędzy każdym cyklem odpuszczania.

Stal nierdzewna 420 jest podatna na kruchość po odpuszczeniu, dlatego należy unikać odpuszczania w temperaturze od 427°C do 566°C (od 800°F do 1050°F).

Odpuszczanie w temperaturach od 400°C do 600°C może prowadzić do spadku odporności na korozję. W tych temperaturach odpuszczania w stali wytrącają się grubsze węgliki chromu (Cr23C6), a wokół nich tworzą się obszary zubożone w chrom, co prowadzi do spadku odporności na korozję. Zjawisko to nazywa się sensytyzacją.1.

Powyższe informacje opierają się na naszym 20-letnim doświadczeniu w produkcji stali narzędziowej oraz naszej wiedzy specjalistycznej w zakresie obróbki cieplnej stali nierdzewnej 420. Niektóre informacje pochodzą również z publikacji naukowych. W przypadku pytań dotyczących stali nierdzewnej 420 prosimy o kontakt.

- Pramanik, A. i Basak, AK (red.). (2016). Stal nierdzewna: mikrostruktura, właściwości mechaniczne i metody zastosowań (str. 125). Apple Academic Press. ↩︎

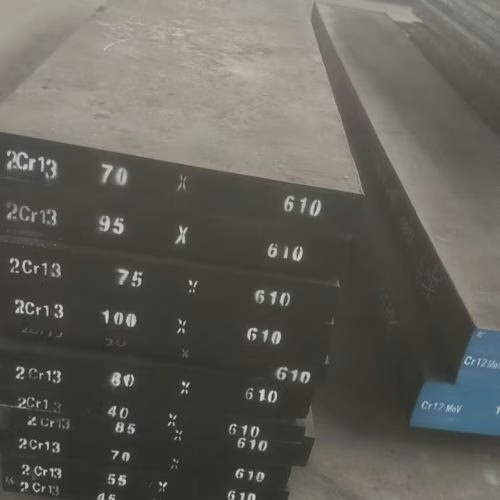

Uzyskaj konkurencyjną ofertę na stal nierdzewną 420/2Cr13

Z ponad 20-letnim doświadczeniem w kuciu, Aobo Steel jest Twoim zaufanym partnerem w zakresie wysokowydajnej stali nierdzewnej 420/2Cr13. Dostarczamy nie tylko materiały, ale i rozwiązania. Wykorzystaj naszą dogłębną wiedzę branżową i niezawodny łańcuch dostaw, aby Twój projekt odniósł sukces.

✉ Skontaktuj się z nami wypełniając poniższy formularz.