Sklepy klientów

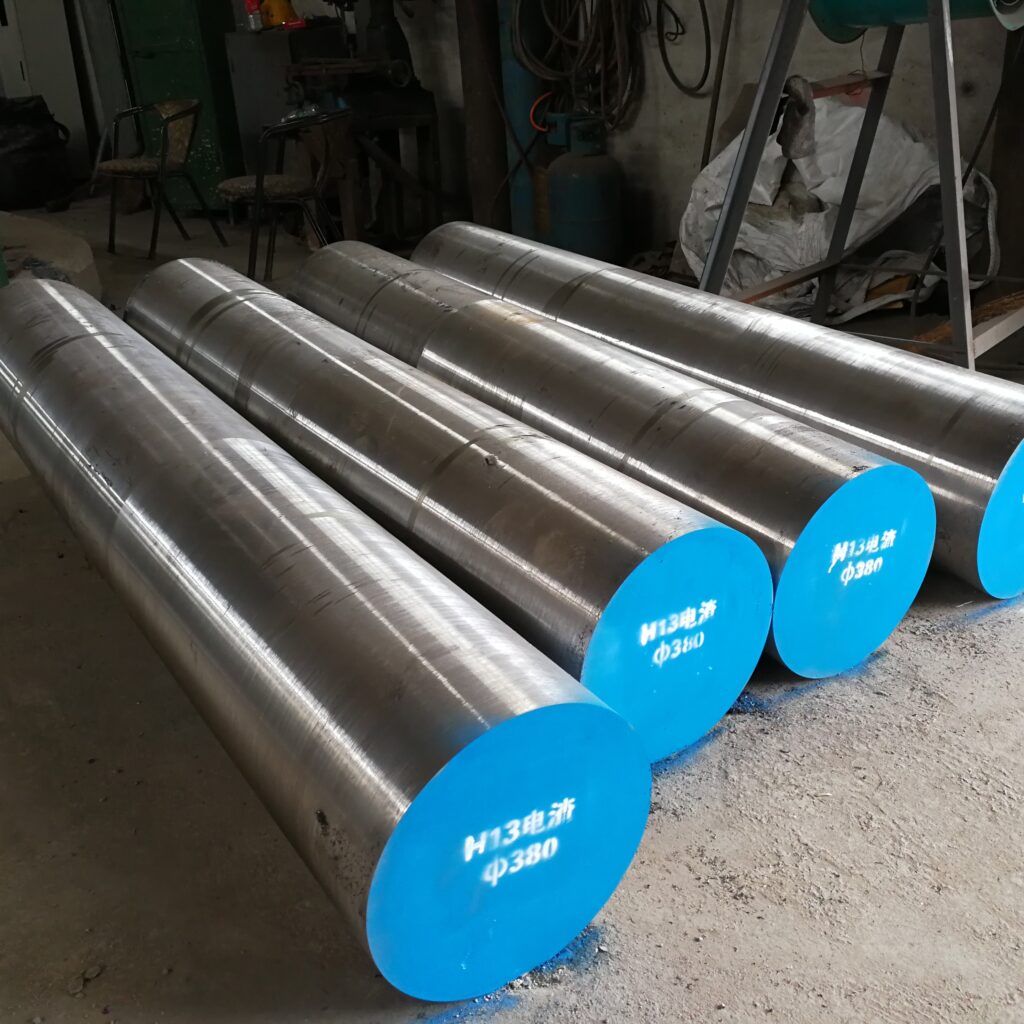

PONIŻSZE HISTORIE NASZYCH KLIENTÓW SĄ PRAWDZIWE. ABY CHRONIĆ PRYWATNOŚĆ NASZYCH KLIENTÓW, NIE PODAWAMY ICH NAZW. Historie indyjskiego klienta W 2017 roku mieliśmy zaszczyt nawiązać współpracę z jednym z największych importerów stali narzędziowej w Indiach, dzięki wprowadzeniu od jednego z naszych […]

Sklepy klientów Przeczytaj więcej »