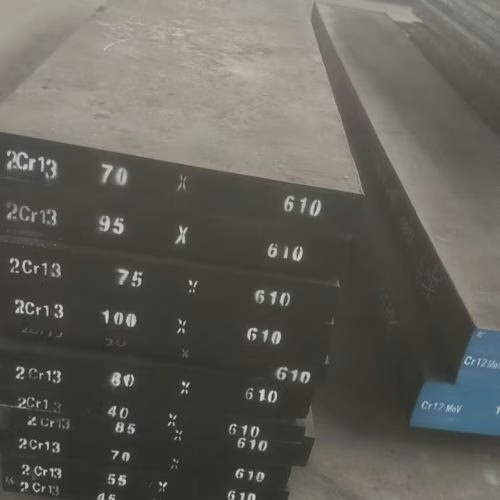

الفولاذ المقاوم للصدأ 2Cr13 مادة متعددة الاستخدامات تُستخدم على نطاق واسع في تصنيع القوالب البلاستيكية، وخاصةً تلك التي تتطلب توازنًا بين القوة والمتانة ومقاومة التآكل. وباعتباره فولاذًا مقاومًا للصدأ مارتنسيتيًا منخفض الكربون، يُستخدم عادةً بعد الإخماد والتطبيع. تُحسّن هذه المعالجة الحرارية خصائصه الميكانيكية، مما يجعله مناسبًا للتطبيقات الصعبة.

من أهم مزايا فولاذ 2Cr13 سهولة تشغيله، مما يسمح بمعالجته وتشكيله بكفاءة. بعد المعالجة الحرارية، يتميز بمقاومة ممتازة للتآكل، مما يضمن طول عمره حتى في البيئات القاسية. كما يجمع بين القوة والمتانة.

1. التركيب الكيميائي (GB/ T 094—1997)

| ج | سي | من | كر | س | ص |

| 0.16 ~ 0.25 | ≤1.00 | ≤1.00 | 12.00 ~ 14.00 | ≤0.030 | ≤0.030 |

2. الخصائص الفيزيائية للفولاذ المقاوم للصدأ 2Cr13

2.1 درجات الحرارة الحرجة

| نقطة حرجة | التيار المتردد₁ | AC₃ | أر₁ | آنسة |

| درجة الحرارة (القيمة التقريبية) /°م | 820 | 950 | 780 | 320 |

2.2 معامل المرونة

| درجة الحرارة /°م | 20 | 400 | 500 | 600 |

| معامل المرونة هـ/ميجا باسكال | 210000 ~ 223000 | 193000 | 184000 | 172000 |

2.3 معامل التمدد الخطي

| درجة الحرارة /°م | 20 ~ 100 | 20 ~ 200 | 20 ~ 300 | 20 ~ 400 | 20 ~ 500 |

| معامل التمدد الخطي α/×10⁻⁶ ℃⁻¹ | 10.5 | 11.0 | 11.5 | 12.0 | 12.0 |

2.4 التوصيل الحراري

| درجة الحرارة /°م | 20 ~ 100 | 20 ~ 200 | 20 ~ 300 | 20 ~ 400 | 20 ~ 500 |

| الموصلية الحرارية λ/[W/(m·K)] | 23.0 | 23.4 | 24.7 | 25.5 | 26.3 |

2.5 المقاومة الكهربائية لفولاذ SM2Cr13

| درجة الحرارة /°م | 20 | 100 |

| المقاومة الكهربائية ρ/×10⁻⁶ Ω·m | 0.55 | 0.65 |

2.6 خصائص فيزيائية أخرى

| الكثافة / (جم/سم³) | السعة الحرارية النوعية cₚ / [J/(kg·K)] | نقطة الانصهار / درجة مئوية |

| 7.75 | 459.8 | 1450 ~ 1510 |

3. مواصفات عملية التشكيل للفولاذ المقاوم للصدأ 2Cr13

| التدفئة | درجة حرارة التشكيل الأولية/°م | درجة حرارة التشكيل النهائية/°م | تبريد |

| تسخين بطيء قبل 850 درجة مئوية، درجة حرارة شحن الفرن البارد ≤800 درجة مئوية | 1160 ~ 1200 | ≥850 | تبريد الرمل أو التلدين في الوقت المناسب |

ملحوظة: بسبب الموصلية الحرارية الضعيفة للصلب، يجب تسخينه ببطء عندما تكون درجة الحرارة أقل من 856 درجة مئوية.

4. العمل البارد

تتميز هذه المادة بسهولة المعالجة بالسحب العميق والختم في الحالة الباردة. بعد المعالجة، يجب إجراء التلدين لتخفيف الإجهاد. وتتم هذه العملية بتسخين قطعة العمل إلى 730-780 درجة مئوية، ثم تبريدها بالهواء.

يرجى ملء النموذج التالي للتواصل معنا للحصول على عرض الأسعار الأكثر تنافسية على الفولاذ المقاوم للصدأ 2Cr13.

5. المعالجة الحرارية للفولاذ المقاوم للصدأ 2Cr13

5.1 التسخين المسبق

| عملية المعالجة الحرارية المسبقة | درجة حرارة التسخين (°م) | طريقة التبريد | الصلابة (HBW) |

| التلدين والتليين | 750 ~ 800 | تبريد الفرن | — |

| التلدين الكامل | 860 ~ 900 | تبريد الفرن | 160 ~ 187 |

5.2 مواصفات عملية التبريد والتهدئة

| مواصفات التبريد | مواصفات التلطيف | ||||

| درجة حرارة التبريد (°م) | طريقة التبريد | الصلابة (HRC) | درجة حرارة التقسية (درجة مئوية) | طريقة التبريد | الصلابة (HRC) |

| 1000 ~ 1050 | التبريد بالزيت أو الماء | ≥45 | 660 ~ 670 | تبريد الهواء | 20 ~ 23 |

العلاقة بين درجة حرارة التلطيف والصلابة

| درجة حرارة التقسية (درجة مئوية) | بعد الإخماد | 200 | 300 | 400 | 500 | 550 | 600 | 650 |

| الصلابة (HRC) | 47 | 46 | 45 | 44 | 43 | 37 | 30 | 24 |

ملحوظة: تبريد الزيت عند درجة حرارة 1050 درجة مئوية.

6. الخصائص الميكانيكية للفولاذ المقاوم للصدأ 2Cr13

2Cr13 هو فولاذ مقاوم للصدأ مارتنسيتي يتميز بمتانة عالية ومقاومة للتشوه وسهولة تشغيل ممتازة. بعد المعالجة الحرارية، يتميز بقوة وصلابة عالية ومقاومة ممتازة للتآكل.

1) الخصائص الميكانيكية عند درجات حرارة مختلفة.

| درجة حرارة التلطيف /°C | رم /ميجا باسكال | رإل /ميجا باسكال | ز (%) | أ (%) |

| 300 | 1580 | 1430 | 10 | 5 |

| 400 | 1550 | 1390 | 11 | 5.5 |

| 500 | 1460 | 1250 | 15 | 7.5 |

| 600 | 1150 | 900 | 22 | 14 |

| 700 | 780 | 580 | 27 | 19 |

| 800 | 800 | 600 | 26 | 16 |

ملحوظة: تبريد الزيت عند درجة حرارة 100 درجة مئوية.

2) الخواص الميكانيكية عند درجات الحرارة العالية

| المعالجة الحرارية | درجة حرارة الاختبار (°م) | رم (ميجا باسكال) | رإل (ميجا باسكال) | أ (%) | ز (%) | أك (جول/سم²) |

| التبريد عند درجة حرارة 1000 إلى 1020 درجة مئوية، والتكييف عند درجة حرارة 720 إلى 750 درجة مئوية | 20 | 720 | 520 | 21 | 68 | 65 ~ 175 |

| 300 | 555 | 400 | 18 | 66 | 120 | |

| 400 | 530 | 405 | 16.5 | 58.5 | 205 | |

| 450 | 495 | 380 | 17.5 | 57 | 240 | |

| 470 | 495 | 420 | 22.5 | 71 | ||

| 500 | 440 | 365 | 32.5 | 75 | 250 | |

| 550 | 350 | 285 | 36.5 | 83.5 | 223 |

3) الخصائص الميكانيكية لدرجة حرارة الغرفة

| حجم القسم / مم | المعالجة الحرارية | R م / ميجا باسكال | R eL / ميجا باسكال | أ (%) | ز (%) | أ ك / (جول/سم²) | صلابة HBW |

| ≤60 | 1000 ~ 1050 درجة مئوية التبريد (الزيت، تبريد الماء)، 600 ~ 770 درجة مئوية التبريد، الزيت، الماء، تبريد الهواء | ≥660 | ≥450 | ≥16 | ≥55 | ≤80 | ≤197 |

| 1000 ~ 1050 درجة مئوية، التبريد (الزيت، تبريد الماء)، 660 ~ 770 درجة مئوية | 660 ~ 1155 | 450 ~ 975 | 16 ~ 33.6 | 55 ~ 78 | 80 ~ 267 | 126 ~ 197¹ | |

| التلدين عند درجة حرارة 860 درجة مئوية | 500 | 250 | 22 | 45 | 90 | ||

| تبريد الهواء 1050 درجة مئوية، وتلطيف 500 درجة مئوية | 1250 | 950 | 7 | 55 | 50 | ||

| تبريد الهواء عند 1050 درجة مئوية، وتلطيف عند 600 درجة مئوية | 850 | 650 | 10 | 63.5 | 70 | ||

| تبريد الزيت عند درجة حرارة 1050 درجة مئوية، وتلطيف عند درجة حرارة 660 درجة مئوية | 860 | 710 | 19 | 66.5 | 130 | ||

| تبريد الزيت عند درجة حرارة 1050 درجة مئوية، وتلطيف عند درجة حرارة 770 درجة مئوية | 820 | 700 | 18 | 150 |

4) قوة الزحف والتمزق

| درجة حرارة الاختبار /°م | 450 | 470 | 500 | 530 |

| R_m (1000h) /ميجا باسكال | 330 | 260 | 230 | 160 |

| R_m (10000h) /ميجا باسكال | 296 | 215 | 195 | 105 |

| R_m (100000h) /ميجا باسكال | 260 | 190 | 160 | 76 |

5) قوة الزحف

| درجة حرارة الاختبار /°م | 450 | 475 | 500 | 550 |

| سي-1 (100000 ساعة) / ميجا باسكال | 128 | 75 | 48 | 38 |

ملحوظة: تم تبريد الفولاذ الاختباري بالهواء عند درجة حرارة تتراوح بين 1000 و1020 درجة مئوية وتم تلطيفه عند درجة حرارة تتراوح بين 720 و730 درجة مئوية.

5) مقاومة التآكل

| واسطة | التركيز (الكسر الكتلي، %) | درجة الحرارة/°م | مدة الاختبار/ساعة | عمق التآكل/(مم/أ) |

| حمض النيتريك | 5 | 20 | — | <0.1 |

| حمض النيتريك | 5 | غليان | — | 3.00~10.0 |

| حمض النيتريك | 20 | 20 | — | <0.1 |

| حمض النيتريك | 20 | غليان | — | 1.0~3.0 |

| حمض النيتريك | 30 | غليان | — | <3.0 |

| حمض النيتريك | 50 | 20 | — | <0.1 |

| حمض النيتريك | 50 | غليان | — | <3.0 |

| حمض النيتريك | 65 | 20 | — | <0.1 |

| حمض النيتريك | 65 | غليان | — | 3~10 |

| حمض النيتريك | 90 | 20 | — | <0.1 |

| حمض النيتريك | 90 | غليان | — | أقل من 10.0 |

| حامض الستريك | 5 | 140 | — | أقل من 10.0 |

| حامض الستريك | 10 | غليان | — | >10.0 |

| حمض اللاكتيك | الكثافة النسبية 1.01 ~ 1.04 | غليان | 72 | >10.0 |

| حمض اللاكتيك | الكثافة النسبية 1.04 | 20 | 600 | 0.27 |

| حمض الفورميك | 10 ~ 50 | 20 | — | <0.1 |

| حمض الفورميك | 10 ~ 50 | غليان | — | >10.0 |

| حمض الساليسيليك | 20 | — | <0.1 | |

| حمض الستياريك | >100 | — | <0.1 | |

| حمض البيروغاليك | محلول مخفف ~ مركز | 20 | — | <0.1 |

| ثاني أكسيد الكربون وحمض الكربونيك | جاف | أقل من 100 | — | <0.1 |

| ثاني أكسيد الكربون وحمض الكربونيك | رطب | أقل من 100 | — | <0.1 |

| السليلوز | أثناء التبخير | — | 190 | 2.59 |

| السليلوز | في خزان الملاط | — | 240 | 0.369 |

| السليلوز | مع حمض البيروكسيتيك في الخزان | — | 240 | 22.85 |

| هيدروكسيد الصوديوم | 20 | 50 | — | <0.1 |

| هيدروكسيد الصوديوم | 20 | غليان | — | أقل من 1.0 |

| هيدروكسيد الصوديوم | 30 | 100 | — | أقل من 1.0 |

| هيدروكسيد الصوديوم | 40 | 100 | — | أقل من 1.0 |

| هيدروكسيد الصوديوم | 50 | 100 | — | 1.0~3.0 |

| هيدروكسيد الصوديوم | 60 | 90 | — | أقل من 1.0 |

| هيدروكسيد الصوديوم | 90 | 300 | — | >10.0 |

| هيدروكسيد الصوديوم | منصهر | 318 | — | >10.0 |

| حمض البوريك | 50 ~ محلول مشبع | 100 | — | <0.1 |

| حمض الخليك | 1 | 90 | — | <0.1 |

| حمض الخليك | 5 | 20 | — | أقل من 1.0 |

| حمض الخليك | 5 | غليان | — | >10.0 |

| حمض الخليك | 10 | 20 | — | أقل من 1.0 |

| حمض الخليك | 10 | غليان | — | >10.0 |

| حمض الطرطريك | 10 ~ 50 | 20 | — | <0.1 |

| حمض الطرطريك | 10 ~ 50 | غليان | — | أقل من 1.0 |

| حمض الطرطريك | محلول مشبع | غليان | — | أقل من 10.0 |

| حامض الستريك | 1 | 20 | — | >0.1 |

| حامض الستريك | 1 | غليان | — | — |

| هيدروكسيد البوتاسيوم | 25 | غليان | — | — |

| هيدروكسيد البوتاسيوم | 50 | 20 | — | — |

| هيدروكسيد البوتاسيوم | 50 | غليان | — | — |

| هيدروكسيد البوتاسيوم | 68 | 120 | — | — |

| هيدروكسيد البوتاسيوم | منصهر | 300 | — | >10.0 |

| الأمونيا | المحلول والغاز | 20 ~ 100 | — | <0.1 |

| نترات الأمونيوم | حوالي 65 | 20 | — | 0.0011 |

| نترات الأمونيوم | حوالي 65 | 125 | — | 1.43 |

| كلوريد الأمونيوم | محلول مشبع | غليان | 1269 | أقل من 10.0 |

| بيروكسيد الهيدروجين | 20 | 20 | 110 | 0 |

| اليود | جاف | 20 | — | <0.1 |

| اليود | حل | 20 | — | >10.0 |

| بروموفورم | بخار | 60 | — | <0.1 |

| نترات البوتاسيوم | 25 ~ 50 | 20 | — | <0.1 |

| نترات البوتاسيوم | 25 ~ 50 | غليان | — | أقل من 10.0 |

| نترات البوتاسيوم | 10 | 20 | — | 0.07 |

| كبريتات البوتاسيوم | 10 | غليان | — | 1.18 |

| نترات الفضة | 10 | غليان | 720 | <0.1 |

| نترات الفضة | منصهر | 250 | 96 | >10.0 |

| بيروكسيد الصوديوم | 10 | 20 | — | أقل من 10.0 |

| بيروكسيد الصوديوم | 10 | غليان | — | >10.0 |

| الشب | 10 | 20 | — | 0.1 ~ 1.0 |

| الشب | 10 | 100 | — | أقل من 10.0 |

| ثنائي كرومات البوتاسيوم | 25 | 20 | — | <0.1 |

| ثنائي كرومات البوتاسيوم | 25 | غليان | — | >10.0 |

| كلورات البوتاسيوم | محلول مشبع | 100 | — | <0.1 |

6. الدرجات المكافئة

- DIN الألماني: رقم المادة 1.4021، الدرجة X20Cr13

- بكالوريوس العلوم البريطاني: الدرجة S62

- اللغة الإنجليزية البريطانية: الصفوف 56B/56C

- AFNOR الفرنسية: الدرجة Z20C13

- أمريكي AISI: 420

التعليمات

2Cr13 هو فولاذ مقاوم للصدأ مارتنسيتي. يتكون تركيبه الكيميائي النموذجي من 0.16-0.25% من الكربون (C)، و≤0.60% من السيليكون (Si)، و≤0.80% من المنغنيز (Mn)، و12.00-14.00% من الكروم (Cr)، و≤0.030% من الكبريت (S)، و≤0.035% من الفوسفور (P). يُستخدم غالبًا في الأجزاء التي تتطلب إجهادًا عاليًا، مثل شفرات التوربينات، وأعمدة مضخات الزيت الساخن، والمراوح، وصمامات الضغط الهيدروليكي.

يُعدّ فولاذ 2Cr13 مثاليًا للتطبيقات التي تتطلب مقاومة ممتازة للتآكل، وقابلية للتلميع، وقوة تحمل عالية، ومقاومة للتآكل بعد المعالجة الحرارية. وهو مناسب للأجزاء المعرضة لضغط عالٍ وفي بعض البيئات التآكلية، بما في ذلك مكونات صناعة الورق، والأدوات الطبية، والأدوات المنزلية مثل أدوات المائدة. ومع ذلك، قد تكون قابليته للحام ضعيفة، وقد يكون أقل صلابة ومقاومة للتآكل مقارنةً ببعض أنواع الفولاذ المقاوم للصدأ الأخرى مثل فولاذ 12Cr13.

عمليًا، غالبًا ما يُقارن الفولاذ المقاوم للصدأ 2Cr13 مباشرةً بالفولاذ المقاوم للصدأ AISI/SAE 420 أو يُعادله. كلاهما يحتوي على نسبة كروم متشابهة (12-14%)، ونسبة كربون تتراوح عادةً بين 0.15% و0.25%. كلاهما من أصناف مارتنسيتية وقابل للتصلب.

الفرق الأساسي بين الفولاذ المقاوم للصدأ 2Cr13 و 3Cr13 يكمن في محتوى الكربون.

2Cr13: يحتوي على 0.16-0.25% الكربون.

3Cr13: يحتوي على نسبة كربون أعلى تتراوح بين 0.26 و0.35%. هذا المحتوى العالي من الكربون في 3Cr13 يُعطي قوة وصلابة وقابلية تصلب أكبر مقارنةً بـ 2Cr13 (و12Cr13) بعد الإخماد. مع ذلك، قد تكون صلابة 3Cr13 ومقاومته للتآكل أقل بقليل من 2Cr13. كلاهما من الفولاذ المقاوم للصدأ المارتنسيتي.

احصل على عرض أسعار تنافسي للفولاذ المقاوم للصدأ 2Cr13

بخبرة تزيد عن 20 عامًا في مجال التشكيل، تُعدّ Aobo Steel شريكك الموثوق في الفولاذ المقاوم للصدأ 2Cr13 عالي الأداء. لا نوفر المواد فحسب، بل الحلول أيضًا. استفد من معرفتنا العميقة بالصناعة وسلسلة التوريد الموثوقة لنجاح مشروعك.

✉ تواصل معنا عن طريق ملء النموذج أدناه.

استكشف منتجاتنا الأخرى

D2/1.2379/1.2379/SKD11

D3/1.2080/1.2080/SKD1

D6/1.2436/SKD2

A2/1.23663/1/SKD12

O1/1.2510/1.2510/SKS3

O2/1.2842

S1/1.2550

S7/1.2355

DC53

H13/1.2344/1.2344/SKD61

H11/1.2343/1.2343/SKD6

H21/1.2581/SKD7

L6/1.2714/SKT4

م2/1.3343/1.3343/سخ 51

M35/1.3243/1.3243/SK55

M42/1.3247/1.3247/SK59

P20/1.2311

P20+Ni/1.2738

420/1.2083/2Cr13

422 الفولاذ المقاوم للصدأ

محمل فولاذي 52100

الفولاذ المقاوم للصدأ 440C

4140/42CrMo4/SCM440

4340/34CrNiMo6/1.6582

4130

5140/42Cr4/SCR440

SCM415