Welcome to learn about our core equipment—the 5-ton medium frequency furnace. With a 5-ton capacity, it meets small to medium-scale production needs while balancing flexibility and energy efficiency. The furnace is equipped with an intelligent control system that monitors key parameters like temperature and pressure in real time, guaranteeing the stability and consistency of every batch. Additionally, we have deep partnerships with electric arc furnace manufacturers to serve high-volume customers, such as those requiring 1.2714 mold steel, with a typical minimum order of 30 tons. Whether for small or large-scale production, we are committed to providing high-quality tool steel and being your trusted partner.

As a professional tool steel manufacturer, we are committed to providing our customers with the highest quality material solutions. Our ESR (Electroslag Remelting) equipment uses advanced technology to precisely control the melting process, effectively removing impurities and non-metallic inclusions from the steel. This significantly improves the purity and uniformity of the material. Our ESR equipment ensures excellent mechanical properties, fatigue resistance, and durability, whether it’s high-hardness, wear-resistant tool steel, or special alloy steel for demanding conditions. With a focus on innovation and strict quality standards, we deliver reliable high-end tool steel products to help industries achieve top performance and efficiency.

We understand that high-quality mold steel starts with precise forging processes. Our experienced forging team can meticulously control every detail of the process to meet customer requirements, ensuring products with excellent mechanical properties and dimensional accuracy.

Whether you need small precision mold steel components or large mold steel parts, we are here to provide professional forging solutions tailored to your needs.

In the process of smelting tool steel, we utilize advanced vacuum degassing equipment (VD) to ensure the highest standards of steel purity and performance. The vacuum degassing process treats molten steel in a vacuum environment, effectively removing harmful gases (such as hydrogen, oxygen, and nitrogen) and non-metallic inclusions. This significantly enhances the density and mechanical properties of the steel. The process improves the toughness and fatigue resistance of mold steel and boosts its corrosion resistance and service life. Our vacuum degassing equipment, combined with precise process control, meets the stringent demands for high-quality mold steel, providing reliable material solutions for your mold manufacturing needs.

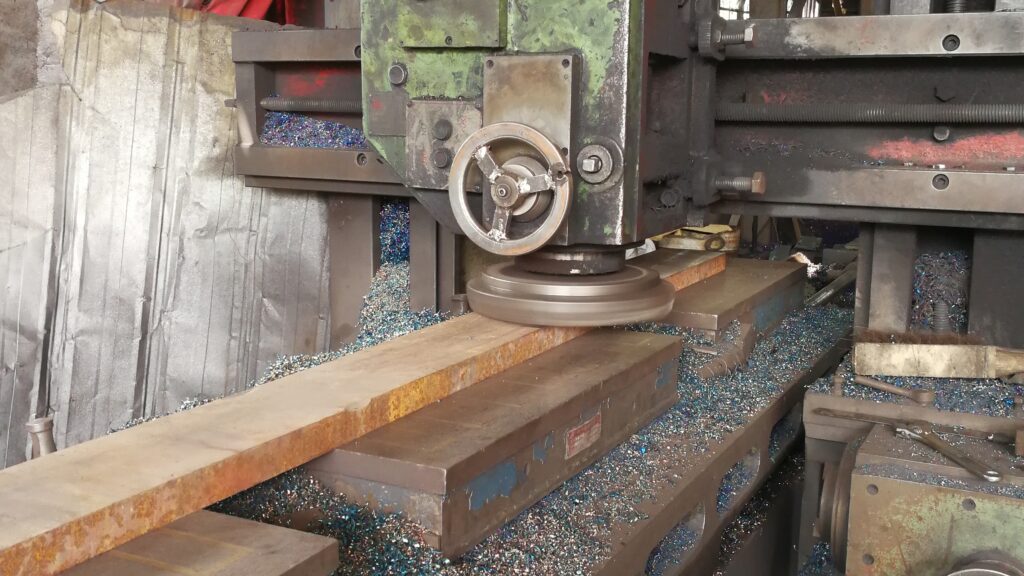

In processing tool steel plates, we use high-precision milling and finishing equipment to ensure optimal surface flatness, smoothness, and dimensional accuracy. Our milling equipment is equipped with advanced CNC systems, enabling efficient and precise processing to meet the needs of various mold steel materials. Our machines operate reliably for large plates or small precision components, ensuring that every mold steel plate meets strict standards for surface quality and dimensional tolerances. We deliver high-quality mold steel plates through meticulous milling and finishing processes, laying a solid foundation for subsequent mold manufacturing.

In tool steel processing, we use high-performance band saw machines to efficiently and accurately cut mold steel materials of various specifications. Our band saws are equipped with advanced cutting systems and stable structures, enabling them to easily handle high-hardness materials, ensuring smooth cutting surfaces and precise dimensions. Whether for large billets or small components, they deliver fast and efficient cutting while minimizing material waste, providing reliable support for subsequent precision machining and mold manufacturing.

We use advanced annealing furnace equipment in tool steel processing to optimize the material’s internal structure and properties. Our annealing furnaces are equipped with precise temperature control systems, allowing accurate heating, insulation, and cooling management. This eliminates internal stress and enhances mold steel’s hardness, toughness, and machinability. Whether for large billets or small components, the furnaces ensure even heating, delivering ideal annealing results and providing customers with stable and reliable mold steel materials.

As a professional tool steel supplier, we are equipped with advanced turning facilities to meet diverse customer needs:

Standard Turning Equipment: For tool steel round bars with diameters over 220mm, ensuring high precision and excellent surface quality.

Centerless Turning Equipment: For tool steel round bars with diameters under 220mm, delivering efficient production and mirror-like finishes.

We are committed to providing high-quality tool steel products and comprehensive processing services to our customers.