Najważniejsze wnioski

- H13, H11, and H21 steel are top choices for hot-working applications due to their unique properties and performance under extreme conditions.

- H13 offers excellent wear resistance and is ideal for high-stress environments like die-casting molds and hot forging dies.

- H11 is known for its toughness, ductility, and high strength, making it suitable for aerospace components and high-speed forging dies.

- H21 excels in high temperatures, providing exceptional red hardness and softening resistance for hot extrusion and forging applications.

- Choosing among H13, H11, and H21 steel depends on specific needs like wear resistance, toughness, and thermal hardness.

Szacowany czas czytania: 9 minut

Spis treści

Ekstremalne temperatury i ciśnienia występujące w zastosowaniach obróbki na gorąco, takich jak kucie, odlewanie ciśnieniowe i wytłaczanie, stanowią poważne wyzwanie dla stali narzędziowych, często prowadząc do ich uszkodzenia z powodu zużycia, odkształceń plastycznych i zmęczenia cieplnego. Wybór stali narzędziowej, która zachowuje wydajność w trudnych warunkach i zapobiega przedwczesnym awariom, jest kluczowy dla osiągnięcia wydajnej i ekonomicznej produkcji. W przypadku stali narzędziowych do obróbki na gorąco serii AISI H, H11, H13, I H21 to popularne wybory do zastosowań wysokotemperaturowych. Choć należą do stali do pracy na gorąco, każda z nich charakteryzuje się odmiennymi właściwościami, odpowiednimi do różnych scenariuszy. Niniejszy artykuł ma na celu przedstawienie przejrzystego i profesjonalnego porównania stali H11, H13 i H21, pomagając czytelnikom w wyborze najbardziej ekonomicznego i wydajnego materiału do ich konkretnych projektów. Koncentruje się na wyjaśnieniu kluczowej równowagi między wytrzymałością, odpornością na ciepło (twardością cieplną) a kosztem.

Czym są stale narzędziowe do pracy na gorąco

Stal narzędziowa do pracy na gorąco to materiał stosowany w procesach obróbki plastycznej metali w wysokich temperaturach i ciśnieniach, takich jak kucie, odlewanie ciśnieniowe i wytłaczanie. Jego główne cechy to wyjątkowa twardość termiczna (znana również jako twardość czerwona lub odporność na odpuszczanie), czyli zdolność do utrzymania wysokiej twardości i wytrzymałości w warunkach pracy w wysokich temperaturach (zwykle od 200°C do 600°C lub wyższych, co odpowiada 390°F do 1100°F). Ponadto muszą one charakteryzować się doskonałą wytrzymałością, aby wytrzymać wstrząsy mechaniczne i termiczne, a także wysoką odpornością na zmęczenie cieplne, które objawia się pęknięciami cieplnymi (drobnymi pęknięciami powierzchniowymi) spowodowanymi powtarzającymi się cyklami nagrzewania i chłodzenia.

Ten Amerykański Instytut Żelaza i Stali (AISI) klasyfikuje stale narzędziowe na wiele kategorii, przy czym „seria H” odnosi się konkretnie do stali narzędziowych do pracy na gorąco. AISI H11 i H13 to stale narzędziowe do pracy na gorąco na bazie chromu, oferujące zrównoważone właściwości i szerokie zastosowanie; natomiast AISI H21 to stal narzędziowa do pracy na gorąco na bazie wolframu. W porównaniu do H11 i H13, H21 zawiera wolfram. Te różnice w składzie chemicznym bezpośrednio przekładają się na różnice w parametrach użytkowych, takich jak odporność na ciepło i szok termiczny.

W skrócie: Tabela porównawcza H13, H11 i H21

Aby ułatwić szybkie zrozumienie różnych profili wydajności, poniższa tabela zawiera bezpośrednie porównanie techniczne stali narzędziowych do pracy na gorąco AISI H13, H11 i H21, podkreślając ich główne cechy, twardość na gorąco, wytrzymałość, odporność na zużycie i typowe zastosowania.

| Funkcja | H13 (na bazie chromu) | H11 (na bazie chromu) | H21 (na bazie wolframu) |

| Stopy podstawowe | Cr, Mo, V | Cr, Mo, V | W, Cr, V |

| Kluczowe cechy | Hartowanie wtórne; głębokie utwardzanie w powietrzu (niskie odkształcenia); doskonała odporność na ciepło, zużycie i zmęczenie cieplne; wyższa zawartość V | Utwardzanie wtórne; głębokie utwardzanie w powietrzu (minimalne naprężenia/zmiany wymiarów); dobra ciągliwość, odporność na zmęczenie i stabilność termiczna do 540°C (1000°F); dobra spawalność | Maksymalna wytrzymałość na gorąco i odporność na zmiękczanie; mniejsza wytrzymałość; większa podatność na kruchość; wymaga wyższych temperatur hartowania; podatność na kruchość podczas hartowania |

| Twardość na gorąco / odporność na odpuszczanie | Wysoka; dobrze sprawdza się w temperaturach do 700°C (1300°F); lepsza od H11 w wysokich temperaturach/długim okresie ekspozycji | Dobry; odporny na zmiękczenie do 540°C (1000°F); mniej odporny niż H21 w wyższych temperaturach | Bardzo wysoka; doskonała odporność na mięknięcie i erozję w wysokiej temperaturze dzięki znacznej zawartości W |

| Wytrzymałość | Dobra ogólna jakość; doskonała udarność; nieco niższa wytrzymałość na pękanie niż w przypadku H11 | Wysoka; wyższa wytrzymałość na pękanie niż w przypadku H13; lepsza odporność na kruche pękanie niż w przypadku H19, H21 | Niska do średniej; mniej ciągliwa niż H11; ogólnie bardziej krucha |

| Odporność na zużycie | Bardzo dobry/Doskonały; wyższy niż H11 ze względu na zawartość V | Średni | Maksymalna wytrzymałość na gorąco i odporność na zmiękczanie; mniejsza wytrzymałość; większa podatność na kruchość; wymaga wyższych temperatur hartowania; podatność na kruchość hartowniczą. |

| Typowe zastosowania | Odlewanie ciśnieniowe (Al, Zn, Mg), kucie/wytłaczanie na gorąco, formy do tworzyw sztucznych, ostrza nożyc do cięcia na gorąco, części lotnicze | Matryce do wytłaczania (mosiądz, brąz, stal, stopy wysokotemperaturowe), matryce do wykrawania na gorąco/prasowania, wytrzymałe ostrza do ścinania na gorąco oraz części poddane dużym naprężeniom termicznym. | Średnia do wysokiej; nadaje się do zastosowań w wysokich temperaturach |

Tabela porównawcza odporności na wstrząsy

Na podstawie wyników testu Charpy’ego z karbem „V”

*Wartości oszacowano na podstawie typowych zakresów w celach wizualizacyjnych.

Ocena obrabialności

Na podstawie oceny obrabialności W1 na poziomie 100.

*Wartości oszacowano na podstawie załączonego wykresu w celach wizualnych.

| ASTM | DIN | Temperatura utwardzania | Jako hartowanie (HRC) | 400°C (750°F) | 450°C (840°F) | 500°C (930°F) | 525°C (980°F) | 550°C (1020°F) | 600°C (1110°F) | 625°C (1160°F) |

| H11 | 1.2343 | 1010°C (1850°F) | 55 | 53 | 54 | 54 | 54 | 54 | 46 | 41 |

| H13 | 1.2344 | 1020°C (1870°F) | 55 | 54 | 54 | 55 | 55 | 53 | 47 | 42 |

| H21 | 1.2581 | 1100°C (2010°F) | 50 | 49 | 50 | 51 | 52 | 51 | 50 | 48 |

Jak elementy stopowe definiują wydajność

Niewielkie różnice w składzie chemicznym stali narzędziowych do pracy na gorąco prowadzą do znacznych różnic w ich parametrach użytkowych, w szczególności w zakresie twardości na gorąco, odporności na zużycie i wytrzymałości.

H13 (chrom-molibden-wanad): wszechstronny

Stal H13 zazwyczaj zawiera około 0,38–0,45% węgla, 4,75–5,50% chromu, 1,10–1,75% molibdenu i 0,80–1,20% wanadu. Kluczową cechą odróżniającą ją od stali H11 jest wyższa zawartość wanadu, która zazwyczaj wynosi około 1%. Wanad sprzyja tworzeniu bardzo twardych i stabilnych węglików typu MC, znacznie zwiększając odporność stali na zużycie i, w mniejszym stopniu, jej twardość na gorąco. Dzięki temu stal H13 doskonale nadaje się do obróbki z dużą prędkością skrawania, zastosowań obejmujących materiały twarde lub złuszczające się oraz do obróbki materiałów takich jak aluminium, stale nierdzewne i metale ogniotrwałe, oferując dobrą równowagę właściwości dla różnych matryc do formowania na gorąco.

H11 (Chrom-Molibden): Wytrzymały specjalista

Skład stali H11 jest podobny do składu stali H13, zazwyczaj zawierając 0,33–0,43% węgla, 4,75–5,50% chromu, 1,10–1,60% molibdenu, ale z niższą zawartością wanadu, zazwyczaj 0,30–0,60%. Niższa zawartość wanadu skutkuje nieco niższą odpornością na zużycie w porównaniu ze stalą H13. Jednakże stal H11 charakteryzuje się ogólnie lepszą udarnością i ciągliwością. Jako stal hartowana w powietrzu, wykazuje minimalne naprężenia szczątkowe i zmiany wymiarów po hartowaniu. Stal H11 zachowuje wysoką wytrzymałość i umiarkowaną udarność w podwyższonych temperaturach do 540°C (1000°F) i jest szeroko stosowana w zastosowaniach konstrukcyjnych, szczególnie w technologii lotniczej.

H21 (wolfram-chrom): mistrz wysokich temperatur

Stal H21 charakteryzuje się wysoką zawartością wolframu, zazwyczaj 8,50–10,00%, a także węgla 0,26–0,36%, chromu 3,00–3,75% i wanadu 0,30–0,60%. Wolfram jest głównym źródłem jej wyjątkowej twardości. Wolfram tworzy bardzo twarde, stabilne węgliki, co sprawia, że stal H21 jest wysoce odporna na mięknięcie w temperaturach, w których stale H11 i H13 uległyby znacznemu mięknięciu. Ta wysoka zawartość stopu zwiększa również odporność na „wymywanie” (zużycie erozyjne). Jednak wysoka zawartość stopu powoduje, że stal H21 ma niższą wytrzymałość niż stale H11 i H13. Dlatego stal H21 nadaje się do zastosowań wymagających wysokiej odporności na mięknięcie w podwyższonych temperaturach, ale stosunkowo niższych wymagań dotyczących wytrzymałości.

Wybór trzech materiałów

Kiedy wybrać stal narzędziową H13

Kiedy wybrać stal narzędziową H13? Stal H13 łączy w sobie doskonałą twardość, odporność na zużycie i doskonałą odporność na pękanie termiczne, co czyni ją idealnym wyborem do środowisk o wysokim naprężeniu i wysokiej temperaturze. Główne zastosowania obejmują formy odlewnicze do stopów aluminium, cynku i magnezu, a także formy wtryskowe do tworzyw sztucznych (szczególnie odpowiednie do precyzyjnych części, takich jak soczewki samochodowe). Stal H13 rafinowana metodą elektrorezystancyjną (ESR) charakteryzuje się zwiększoną wydajnością. Jest również szeroko stosowana w matrycach do kucia na gorąco, matrycach do wytłaczania na gorąco do aluminium, magnezu i stali, matrycach do walcowania na gorąco, matrycach do tłoczenia na gorąco, matrycach mocujących, trzpieniach i ostrzach nożyc do cięcia na gorąco. W konstrukcjach lotniczych i rakietowych, które wymagają ultrawysokiej wytrzymałości, jest wykorzystywana do produkcji elementów konstrukcyjnych.

Kiedy wybrać stal narzędziową H11

H11 jest szczególnie odpowiedni do elementów wymagających wysokiej wytrzymałości, ciągliwości, udarności, odporności na zmęczenie i stabilności termicznej w zakresie temperatur od 75 do 540°C (167 do 1000°F). Jest szeroko stosowany w zastosowaniach konstrukcyjnych, zwłaszcza w technologii lotniczej, w tym w elementach podwozi samolotów, częściach płatowca, wewnętrznych elementach turbin parowych i gazowych, elementach złącznych i sprężynach. W produkcji form, H11 sprawdził się w matrycach do szybkiego kucia, matrycach do wytłaczania na gorąco oraz formach odlewniczych do stopów cynku, aluminium i magnezu, szczególnie w przypadku długotrwałej, ciągłej pracy. Nawet w warunkach długotrwałej ekspozycji na temperatury do 540°C (1000°F), H11 zachowuje swoją ciągliwość i udarność, skutecznie zapobiegając jednocześnie mięknięciu.

Kiedy wybrać stal narzędziową H21

Stal H21 nadaje się do zastosowań wymagających wyjątkowo wysokiej wytrzymałości termicznej i odporności na zmiękczanie. Typowe zastosowania obejmują matryce do wytłaczania na gorąco, matryce do prasowania na gorąco, matryce pozorne, ciągowniki do kucia na gorąco, ostrza nożyc do cięcia na gorąco oraz stemple do mosiądzu, brązu i stali. Ten gatunek stali jest również stosowany w matrycach odlewniczych i elementach form mosiężnych poddawanych wysokim naprężeniom termicznym. Stal H21 znajduje również zastosowanie w kuciu stali i stopów wysokotemperaturowych, a także w nożycach do kęsów i walcach walcowanych na gorąco do średnich serii w średnich temperaturach.

Wniosek

Wybierając spośród trzech stali narzędziowych do pracy na gorąco: H13, H11 i H21, należy wziąć pod uwagę takie czynniki, jak odporność na zużycie, udarność i twardość cieplna, w zależności od wymagań konkretnego zastosowania. H13 to wszechstronny, najlepszy wybór, dzięki swoim wszechstronnym właściwościom, odpowiednim do szerokiego zakresu zadań formowania na gorąco i obróbki plastycznej, w tym form odlewniczych i kucia na gorąco. H11 to wybór skoncentrowany na udarności do zastosowań wymagających dużej udarności, a jego wyjątkowa ciągliwość okazuje się nieoceniona w elementach konstrukcyjnych dla przemysłu lotniczego i matrycach do kucia z dużą prędkością. W ekstremalnych warunkach temperaturowych wymagających ścisłego utrzymania twardości, H21 zachowuje wyjątkową twardość w stanie czerwonym i odporność na mięknięcie w wysokich temperaturach.

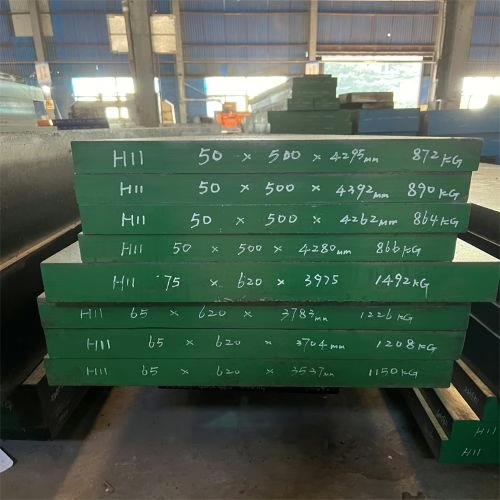

Jeśli interesują Cię gatunki stali narzędziowych H13, H11, H21 lub inne, wypełnij poniższy formularz, aby się z nami skontaktować.