Szacowany czas czytania: 10 minut

Najważniejsze wnioski

- H11 and H13 steels are both AISI hot-work tool steels known for their high strength and hardness at elevated temperatures.

- H13 has a higher vanadium content, enhancing its wear resistance compared to H11, which offers better toughness.

- Both steels require specific heat treatment processes, including preheating and air cooling, to achieve optimal performance.

- Applications vary: H13 excels in high-wear environments, while H11 is preferred where toughness is critical.

- The choice between H11 vs H13 steel depends on the specific needs for wear resistance and toughness in applications.

Spis treści

H11 I H13 steels both belong to the American Iron and Steel Institute (AISI) H series of hot-work tool steels, representing two of the most widely used 5% chromium stale narzędziowe do obróbki na gorąco. These steels are critical materials in manufacturing, with their core advantage being the ability to maintain excellent strength and hardness even under high-temperature working conditions.

Although they share fundamental similarities in properties, subtle differences in chemical composition grant each distinct performance advantages. Therefore, in practical applications, the choice between H11 and H13 should be made carefully based on the specific operating conditions of the mold and the required service life.

H11 and H13 are both medium-alloy air-hardening steels or ultra-high-strength steels. Through appropriate heat treatment processes, their 0.2% proof strength can be elevated to levels far exceeding 1380 MPa.

Classification and Shared Metallurgical Foundation

H11 and H13 both belong to the H10-H19 chromium-based hot-work steel subcategory. They share the same metallurgical foundation, characterized by a medium carbon content and high concentrations of chromium and other carbide-forming elements.

H11 vs. H13 Equivalent Grades:

| US(AISI) | Germany (DIN / W-Nr.) | Japonia (JIS) | Chiny (Wielka Brytania) | UK (BS) |

| H11 | 1.2343(X37CrMoV5-1) | SKD6 | 4Cr5MoSiV | BH11 |

| H13 | 1.2344(X40CrMoV5-1) | SKD61 | 4Cr5MoSiV1 | BH13 |

These two types of steel share three key characteristics:

First, they are used in high-temperature hot-working applications, such as aluminum alloy die casting, and can withstand operating conditions up to 600°C.

Second, they all exhibit extremely high hardenability and are air-hardening steels. Even large steel components can be fully hardened from the inside out simply by cooling in air. Air cooling minimizes internal stresses and dimensional changes generated during heat treatment.

Finally, both H11 and H13 are secondary hardening steels. They must be tempered at temperatures above approximately 510°C to precipitate fine alloy carbides, thereby achieving optimal performance. This high-temperature tempering process not only effectively relieves stress but is also the key reason they maintain stable performance during high-temperature operation. The upper limit of this high-temperature operation must remain below the tempering temperature.

Chemical Composition: The Vanadium Difference

The core difference between H11 and H13 steels lies primarily in their Vanadium (V) content.

H11 and H13 composition

| AISI | Numer UNS | DIN | C (%) | Mn(%) | Si (%) | Cr (%) | Ni (%) | Mo (%) | W (%) |

| H11 | T20811 | 1.2343 | 0.33-0.43 | 0.20-0.50 | 0.80-1.20 | 4.75-5.50 | 0,30 maks. | 1.10-1.60 | 0.30-0.60 |

| H13 | T20813 | 1.2344 | 0.32-0.45 | 0.20-0.50 | 0.80-1.20 | 4.75-5.50 | 0,30 maks. | 1.10-1.75 | 0.80-1.20 |

This difference in Vanadium content is the major differentiator in mechanical performance:

| Funkcja | H11 | H13 |

| Vanadium (V) Content | Lower (e.g., 0.30–0.60%) | Higher (e.g., 0.80–1.25%) |

| Odporność na zużycie | Dobry | Higher, due to V carbides |

| Wytrzymałość | Higher/Better Fracture Toughness | Slightly Lower |

| Hot Hardness/Temper Resistance | Doskonały | Slightly Better |

Performance Showdown: Mechanical Properties

The primary difference in mechanical properties between H11 and H13 stems from their chemical compositions, with H13 possessing a higher vanadium content.

In terms of wear resistance, H13 offers superior performance. Its higher vanadium content promotes the formation of abundant hard vanadium carbides, resulting in wear resistance that surpasses H11. This makes it highly suitable for high-wear applications such as hot forging or hot extrusion.

However, H11 offers superior toughness. The carbide particles used in H13 to enhance wear resistance sometimes come at the expense of some toughness. Therefore, H11 exhibits higher fracture toughness.

In terms of heat hardness, both perform excellently, but H13 holds a slight edge. This is again due to H13 containing more vanadium.

Heat Treatment and Quality Manufacturing

The heat treatment processes for H11 and H13 are critical for maximizing their performance. As both are air-hardening steels, their fundamental heat treatment steps are highly similar, typically including preheating, austenitizing, quenching, and subsequent secondary or tertiary high-temperature tempering.

Standard Heat Treatment

First comes preheating, where the steel should be preheated to between 790°C and 815°C before being uniformly heated to the final forging or austenitizing temperature.

The austenitizing temperature range for H11 steel typically falls between 995°C and 1025°C, while the austenitizing temperature for H13 steel is slightly higher, generally between 995°C and 1040°C. During this step, a controlled protective atmosphere must be employed to prevent decarburization of the steel surface.

Quenching is the third step. H11 and H13 must be cooled in air, as this method ensures minimal residual stress within the material. These steels must never be water-quenched.

Finally, tempering. To achieve secondary hardening and relieve stress, secondary tempering or multiple tempering cycles are strongly recommended. The tempering temperature must exceed the secondary hardening peak of 510°C. For H13 steel specifically, tempering within the 565°C to 650°C range optimizes its secondary hardening effect.

Quality Enhancement (ESR/VAR)

To meet the demands of demanding applications, H11 and H13 steel grades are often subjected to specialized manufacturing processes to enhance their quality and performance further.

In terms of enhancing melting quality, these two steels often employ melting technologies such as przetapianie elektrożużlowe (ESR) or vacuum arc remelting (VAR).

Compared to conventionally melted steels, the ESR or VAR process significantly enhances material ductility and toughness. The VAR process, in particular, achieves extremely low impurity levels and high microstructural uniformity. For high-performance H13 die-casting molds or injection molds, ESR remelting has become a common manufacturing requirement. Our company offers ESR H13 and H11 materials.

Surface Modification

For surface performance enhancement, both H11 and H13 steels typically undergo nitriding treatment. Nitriding is a chemical heat treatment that forms an extremely hardened layer on the steel surface.H11 and H13 achieve high core strength and high surface hardness after nitriding. H13, in particular, exhibits excellent responsiveness to nitriding, with surface hardness reaching 1000-1200 HV. Furthermore, H13’s outstanding resistance to high-temperature tempering ensures that its internal core maintains its original high strength without softening during nitriding heating.

Applications and Selection Criteria

When choosing between H11 and H13, the decision essentially involves balancing H13’s high wear resistance against H11’s high toughness.

- Die Casting Applications: Both are industry benchmarks. H13 has the broadest application range, commonly used for die casting of aluminum, zinc, and magnesium alloys, while H11 is frequently used for die casting of aluminum and lead.

- Hot Forging and Extrusion: H13 is the more versatile choice for hot-work forging dies. H11 is commonly used for punches and dies in aluminum forging (HRC 44-48) or for small-batch hot-rolled rolls.

- Plastic molds: Both materials are suitable. H13 is the superior choice, particularly ESR remelted H13, which is the preferred option for manufacturing high-polish precision molds such as automotive lenses. H11 is suitable for high-temperature plastic molding applications where operating temperatures exceed 300°C.

- Aerospace Structural Components: Both are ultra-high-strength alloys. H11 is more commonly used in high-stress components such as aircraft landing gear and rocket casings, as it must maintain high strength at elevated temperatures. H13 was also widely used in the past, but its application in this field has declined with the advent of new high-toughness steels.

Summary for Selection:

Choose H13 when:

- When high wear resistance is the primary requirement, H13 contains higher levels of vanadium (V), enabling the formation of more dispersed, hard vanadium carbides. This makes it superior to H11 in abrasive wear environments such as hot extrusion and high-wear forging.

- When optimal red hardness and resistance to tempering are required, H13 offers slightly superior stability at elevated temperatures, better preserving hardness and strength under high-heat conditions.

- For general-purpose hot work and die casting molds, H13 remains the most widely used general-purpose hot work tool steel, particularly in die casting mold applications.

Choose H11 when:

- When maximum toughness is required, H11 offers superior fracture toughness and ductility compared to H13, making it a safer choice for applications involving impact loads where preventing unexpected mold cracking is critical.

- When used for high-strength structural components, H11 resists softening and maintains high strength at temperatures up to 540°C, making it commonly used in high-stress aerospace components such as landing gear.

Supplementary data

We have compiled authoritative data on H11 and H13, which we hope will be helpful to our readers.

Porównanie innych parametrów

| Czynnik | Stale narzędziowe H11 | Stale narzędziowe H13 |

| Zwykła twardość robocza, HRC | 38-55 | 40-53(Twardość stali H13) |

| Głębokość hartowania | D | D |

| Najdrobniejszy rozmiar ziarna przy pełnej twardości, standard Shepherd | 8 | 8 |

| Twardość powierzchni po hartowaniu, HRC | 53-55 | 51-54 |

| Twardość rdzenia (średnica 25 mm lub 1 cal, okrągły), HRC | 53-55 | 51-54 |

| Medium hartujące | A | A |

| Temperatura utwardzania, °C (°F) | 995-1025 (1825-1875) | 995-1040 (1825-1900) |

| Zmiana wymiarów podczas hartowania | L | L |

| Bezpieczeństwo podczas hartowania | H | H |

| Podatność na odwęglanie | H | H |

| Przybliżona twardość po walcowaniu lub kuciu, HB | 500 | 500 |

| Twardość wyżarzana, HB | 192-229 | 192-229 |

| Temperatura wyżarzania, °C (°F) | 845-900 (1550-1650) | 845-900 (1550-1650) |

| Zakres temperowania, °C (°F) | 540-650 (1000-1200) | 540-650 (1000-1200) |

| Temperatura kucia, °C (°F) | 1065-1150 (1950-2100) | 1065-1150 (1950-2100) |

H11 and H13 tool steels share many similarities in terms of their mechanical properties, obróbka cieplna charakterystyki i możliwości kucia. Główna różnica leży w zakresie twardości, przy czym H13 oferuje nieco wyższą twardość dla bardziej wymagających zastosowań. Wybór pomiędzy tymi dwoma stalami zależy od konkretnych wymagań zamierzonego zastosowania, takich jak wymagany poziom odporności na zużycie, wytrzymałość i stabilność wymiarowa.

Właściwości rozciągające stali narzędziowych H11 i H13 w podwyższonych temperaturach

| Rodzaj stali | Temperatura testowania (°C) | Temperatura testowania (°F) | Wytrzymałość na rozciąganie (MPa) | Wytrzymałość na rozciąganie (ksi) | Wytrzymałość na rozciąganie (0,2% offset) (MPa) | Wytrzymałość na rozciąganie (przesunięcie 0,2%) (ksi) | Wydłużenie (50 mm) (%) | Redukcja powierzchni (%) | Twardość w temperaturze pokojowej (HRC) przed testowanie | Twardość w temperaturze pokojowej (HRC) po testowanie |

| H11 | Pokój | Pokój | 1806 | 262 | 1482 | 215 | 10 | 35.8 | 50 | 50 |

| 150 | 300 | 1689 | 245 | 1358 | 197 | 10.1 | 36.1 | 50 | 50 | |

| 260 | 500 | 1600 | 232 | 1345 | 195 | 9.8 | 34.5 | 50 | 50 | |

| 345 | 650 | 1579 | 229 | 1317 | 191 | 10 | 35.2 | 50 | 50 | |

| 425 | 800 | 1510 | 219 | 1289 | 187 | 11.4 | 38.7 | 50 | 50 | |

| 480 | 900 | 1427 | 207 | 1145 | 166 | 12.2 | 38.9 | 50 | 50 | |

| 540 | 1000 | 1241 | 180 | 965 | 140 | 11 | 35.4 | 50 | 50 | |

| 595 | 1100 | 979 | 142 | 724 | 105 | 12.8 | 46.2 | 50 | 47 | |

| 650 | 1200 | 586 | 85 | 434 | 63 | 18.9 | 66.6 | 50 | 41 | |

| H13 | 480 | 900 | 1531 | 222 | – | – | 9 | 37 | 52 | – |

| 540 | 1000 | 1413 | 205 | – | – | 11 | 43 | 52 | – | |

| 595 | 1100 | 1193 | 173 | – | – | 15 | 49 | 52 | – | |

| 650 | 1200 | 814 | 118 | – | – | 22 | 59 | 52 | – |

Notatka:

- Znak „-” w kolumnie „Wytrzymałość na rozciąganie” dla stali H13 oznacza, że dane były niedostępne.

- Kolumna Twardość w temperaturze pokojowej (HRC) zawiera wartości przed i po badaniu, oddzielone przecinkiem.

- Dane z Teledyne VASCO. Allegheny Ludlum Industries i Universal-Cyclops Steel Corp.

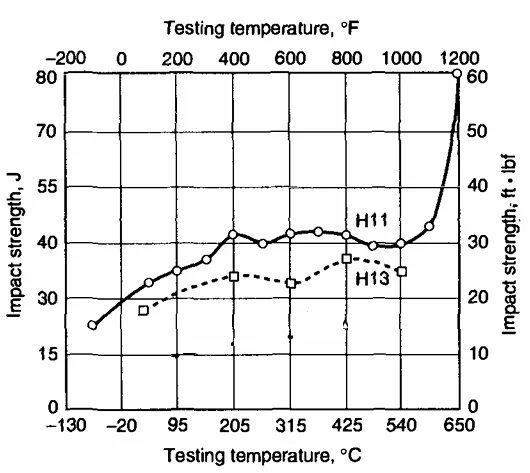

Wytrzymałość na uderzenia CVN stali narzędziowych H11 i H13 w zależności od temperatury badania.

Ten wykres sugeruje, że H11 i H13 stają się bardziej odporne na uderzenia w wyższych temperaturach. Jednak H13 jest bardziej wrażliwy na zmiany temperatury, wykazując bardziej znaczący wzrost wytrzymałości na uderzenia wraz ze wzrostem temperatury.