D2 tool steel and 440C stainless steel are two common types of steel, with D2 tool steel focusing more on wear resistance and 440C stainless steel on corrosion resistance. This article will comprehensively compare these two steels, covering mechanical properties, heat treatment characteristics, typical applications and selection advice.

Mechanical properties-D2 steel vs 440c

Differences in chemical composition directly affect the mechanical properties of D2 tool steel and 440C stainless steel.

· Hardness: D2 tool steel has a hardness of up to 61 HRC, higher than the 58 HRC of 440C. This makes D2 particularly suitable for highly abrasive conditions.

· Wear resistance: D2 tool steel relies on the carbides it contains to provide excellent wear resistance, whereas 440C stainless steel achieves good wear resistance through chromium carbides.

· Toughness: D2 tool steel has medium toughness, superior to 440C stainless steel.

· CORROSION RESISTANCE: 440C stainless steel has better corrosion resistance than D2 tool steel due to its 17% chromium content, and D2 has average corrosion protection.

As a result, D2 tool steel is more advantageous in scenarios requiring high hardness and wear resistance, while 440C stainless steel excels in environments where corrosion resistance is required.

Heat Treatment Properties: Differences in Processes

D2 tool steel and 440C stainless steel have different heat treatment processes, which affect their processing and performance optimization.

·D2 tool steel: A secondary tempering process is required, with a recommended temperature of 500-550°C to control residual austenite content. An austenitizing temperature of 1010°C gives a 62-64 HRC hardness.

·440C Stainless Steel: Typical quenching temperatures are 1040-1060°C and require low-temperature tempering to maintain corrosion resistance. The carbide type is dominated by M23C6.

Typical Applications

D2 tool steel is commonly used in cold work dies such as stamping dies, shear knives, and wire drawing dies, as well as cutting tools and wear parts (e.g., rolls, gauges).

440C stainless steel is more suitable for medical devices, food processing equipment, bearings valve parts, etc., where corrosion resistance is required, especially in wet or corrosive environments.

Suggestions for selection

We can summarize some selection recommendations based on the differences in application areas mentioned above. When choosing D2 tool steel or 440C stainless steel, it is necessary to decide according to the specific needs of the working conditions.

· gives preference to D2 tool steel scenarios:

- Highly abrasive cold work molding processes

- Precision molds requiring 60+ HRC hardness

- Continuous production environments requiring high dimensional stability

· Preferred scenarios for 440C stainless steels:

- Medical devices and food processing equipment

- Marine environment or chemical corrosion environment

- Bearing components that require a balance between wear and rust resistance

Conclusion

D2 tool steel and 440C stainless steel each have their own unique advantages and application scenarios. D2 tool steel excels in high-wear environments with its high hardness and excellent wear resistance, while 440C stainless steel is more advantageous in wet and corrosive environments due to its excellent corrosion resistance. Factors such as working condition requirements, wear resistance, corrosion resistance, and cost should be considered to ensure rational and economical material selection.

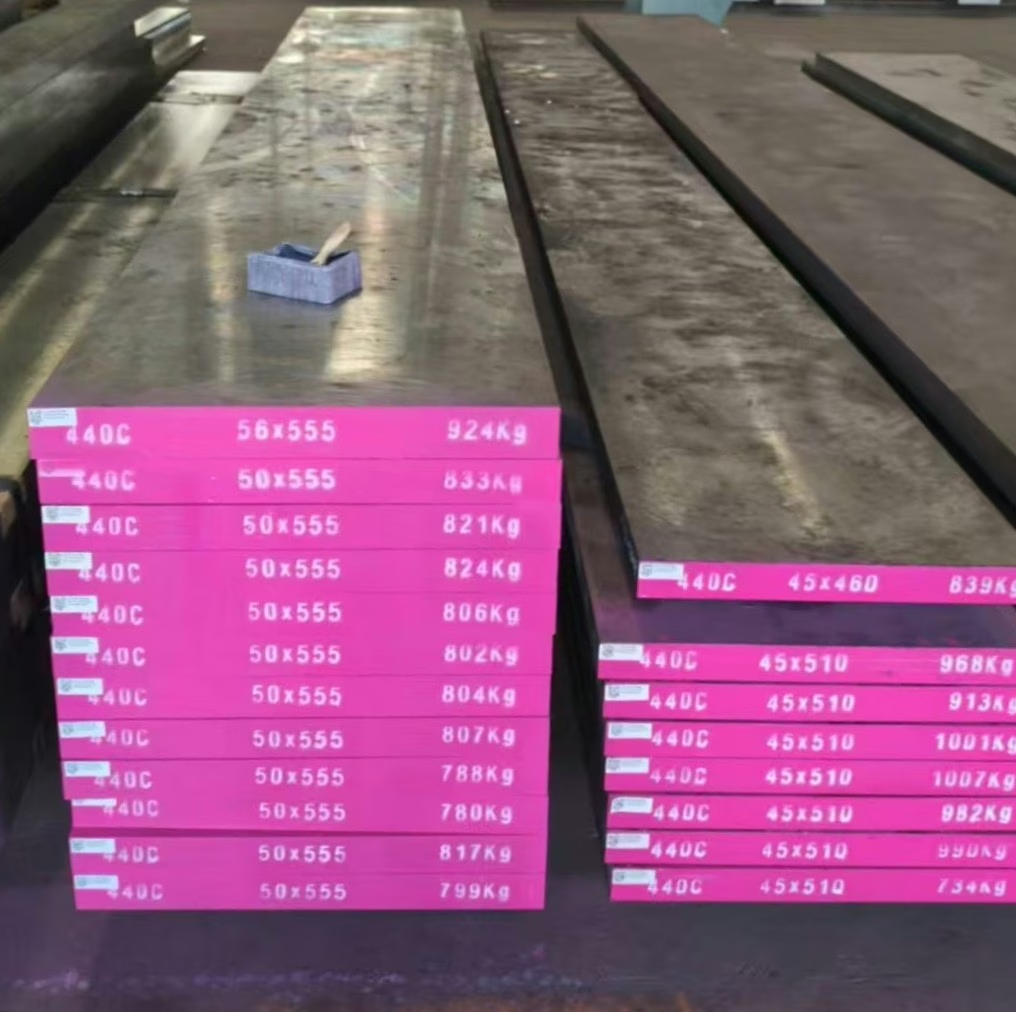

Top-Quality D2 & 440C Steel – Trusted by Professionals Worldwide

- ✅ Direct from Aobo Steel Manufacturer – Best pricing, no middlemen

- ✅ Precision-Cut to Size – Save time and reduce material waste

- ✅ Fast Global Delivery – Secure, on-time shipments worldwide

- ✅ Expert Guidance – Not sure whether D2 or 440C is better for your use? Our team can help!

- ✅ Bulk Discounts Available – Save big on large-volume orders

📩 Request a Free Quote Today – Get a Reply Within 24 Hours!