A2 Tool Steel Technical Overview

A2 steel is a general-purpose, air-hardening tool steel. It’s known for having a good balance of abrasion resistance, toughness, and ductility. A2 offers more abrasion resistance than shock-resistant “S” series steels and better toughness and ductility than the wear-resistant “D” series. Chemically, it typically contains carbon, molybdenum, chromium, and vanadium. A key characteristic of A2 steel is its dimensional stability during heat treatment, with relatively low distortion. Because of these properties, it is widely used in various tooling applications.

1. A2 tool steel chemical composition

| Element | Carbon (C) | Chromium (Cr) | Molybdenum (Mo) | Vanadium (V) | Manganese (Mn) | Silicon (Si) | Phosphorus (P) | Sulfur (S) |

| Percentage (%) | 0.95 – 1.05 | 4.75 – 5.50 | 0.90 – 1.40 | 0.15 – 0.50 | 0.40 – 1.00 | 0.30 – 0.90 | ≤ 0.03 | ≤ 0.03 |

2. A2 steel mechanical properties

| Property | Details |

Hardness | |

| – As-quenched | 63 HRC |

| – Tempered at 300 °F (150 °C) | 62 HRC |

| – Normal working hardness | 58–60 HRC (after air quenching from 1775 °F / 968 °C) |

| – Tempering behavior | Hardness decreases with increasing tempering temperature; good resistance to softening vs. plain carbon and O2 steels |

Strength | |

| – Torsional strength | Peaks after tempering at 150 °C (300 °F); higher than O1 tool steel across tempered conditions |

| – Tensile/Yield strength | Limited data available in broader references, not detailed here |

Ductility and Toughness | |

| – Torsional ductility | Does not significantly decrease during low-temperature tempering |

| – Torsional impact energy | Minimum absorbed energy when tempered at 260 °C (500 °F) |

| – Unnotched impact energy | Good, even when tempered to maintain high hardness |

| – Comparison | Better toughness and ductility than D-series wear steels |

Wear Resistance | Very good; better than S-series shock steels but less than D-series wear steels |

Machinability | A rating of 60 (compared to 1% carbon tool steel at 100) when properly annealed |

Dimensional Stability | Good due to air-hardening nature; expands ~0.001 in./in. (0.001 mm/mm) when air quenched from 1775 °F |

3. A2 Steel Applications

The A2 is a very versatile tool steel with many applications, most notably in cold-work tooling. It is suitable for various purposes due to its key properties, including a good balance of wear resistance and toughness, good dimensional stability during air hardening, and moderate machinability.

Below are specific applications of A2 steel according to its properties:

- Blanking and Piercing Dies: High-abrasion-resistant A2 steel is the ideal material for blanks, particularly in large production quantities, especially where hot-rolled, unpickled steel will be used. It is the most widely used for those applications, a good compromise between wear and breakage.

- Forming Dies: A good combination of wear resistance and toughness makes it useful for many forming operations. This includes applications where the die needs to withstand both abrasive wear and forming stresses.

- Punches: A2 steel is preferred for punches because of its toughness, which is usually more important in punch applications than extreme wear resistance. Although wear resistance is not to be undervalued, grades such as D2 may not possess adequate toughness for a good punch.

- Shear Blades: A2 can be used to make shear blades when moderate wear resistance and high strength are required to endure cutting forces.

- Thread Rolling Dies: A2 steel is one option for thread-rolling dies. It will give a decent life, although not the same as more wear-resistant grades, e.g., D2 or M2, in long production runs.

- Gauges: A2 steel’s dimensionally stable nature, post air hardening, makes it ideal for use as precision gauges, where holding exact dimensions is important.

- Machine Components: A2 steel can be used for machine components such as cams, shafts, and spindles. These components require a good balance between strength, moderate wear resistance, and good dimensional stability.

- Plastic Injection Molds: Martensitic stainless steels are sometimes preferred, but A2 steel can be used for plastic injection molds, particularly in areas where a combination of good wear resistance and good dimensional stability is required.

- Hot Bolt Header Dies, Swaging Dies, and Rivet Busters: Some sources classify these as shock-resisting types, but A2’s toughness and hardness can allow applications that require a combination of wear resistance and strain.

- Coining dies: A2 steel can be utilized for normal coining designs that need close dimensional replication. It provides a fair blend of compression resistance and dimensional stability.

4. A2 steel heat treatment

4.1 Preheat:

- Typically, the process is initiated with a heating period to approximately 1200°F (650°C). This is an essential step to allow heat to equalize in the part and to relieve stresses before the metal becomes too soft.

- Preheating for 10-15 minutes is often advised.

4.2 Austenitizing (Hardening):

- After preheating, the steel is brought to the hardening temperature range, generally around 1775°F (970°C) for A2 steel.

- At this temperature, steel transforms to austenite, into which carbon and the alloying elements are placed in a homogeneous solution.

- A soak time at this austenitizing temperature must be given to allow the part’s cross-section to transform completely and uniformly to austenite. The general soak time is 1 hour per inch (25mm) of thickness. Soaking for too long can also cause problems.

4.3 Quenching:

- A2 steel is an air-hardening steel. This means it is usually air cooled to the range from the austenitizing temperature to obtain hardening.

- The cooling rate is key to the conversion of austenite into martensite.

- To prevent scaling, the steel should not come into contact with the atmosphere until it loses its visible red heat.

- At larger cross-sections (over approximately 5″ or 127mm), air won’t be sufficient to achieve full hardness, and this is when alternate quenching methods, such as oil quenching, may be utilized, though that is not the normal use case for A2 tool steel.

4.4 Tempering:

- The martensite structure formed from quenching is hard but also brittle and has internal stresses. Tempering relieves these stresses and increases toughness.

- Tempering involves reheating the steel to a medium temperature, maintaining it for a certain period, and then cooling it down, often in air.

- The first tempering temperature for A2 steel is about 400°F (205°C).

- The tempering cycle typically involves holding the thinnest cross-section at the tempering temperature for 2 hours/inch (25mm).

- Therefore, a second temper is usually suggested for most tool steels such as A2; the grain structure can further be refined, wear resistance achieved, and additional stress relief given. In our practice, if a second temper is applied to A2, it is usually done at a temperature about 25°F (14°C) lower than the first and for the same time (2 hours per inch of thinnest cross-section). For instance, a second temper could be at 375 °F (190 °C).

4.5 Important Considerations:

- Dimensional Stability During Heat Treatment: As previously mentioned, one of the advantages of A2 steel is good dimensional stability during heat treatment—a 0.001 in./in. (0.001 mm/mm) Expansion can be expected during air quenching. However, distortion can still occur due to variations in part geometry and uneven heating or cooling.

- Retained Austenite: Some retained austenite (austenite that has not been transformed into martensite by this quenched process) may exist. That being said, tempering at stage two, in particular, transforms the retained austenite into more stable forms, thereby enhancing dimensional stability.

- Straightening: If required, after the material has cooled but before it reaches the fully hardened condition, the A2 steel component can be straightened when the temperature is above 400°F (205°C).

Furnace Calibration and Atmosphere — A properly calibrated furnace is crucial for achieving optimal results. Furthermore, heat treatment of A2 steel should, ideally, be executed in a neutral atmosphere, vacuum or neutral-salt furnace environment to prevent decarburization. Wrapping with stainless steel foil can also serve as surface protection while warming up.

By following these steps and adhering to recommended temperatures and times, you can effectively heat treat A2 steel to achieve the desired balance of hardness, toughness, and wear resistance for your factory’s applications.

5. Comparison of A2 and other steels

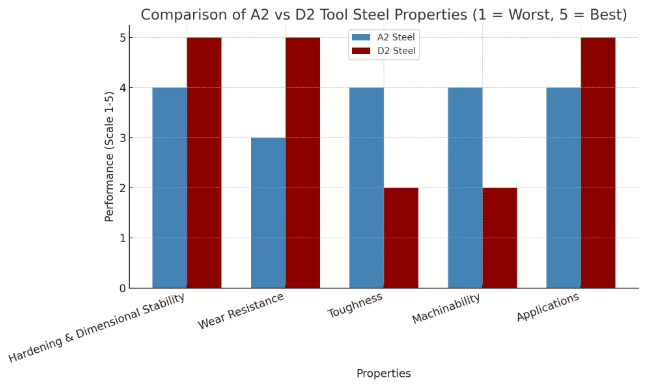

A2 VS D2

The following chart provides a quantitative comparison of the performance of A2 and D2 tool steel, including hardening and dimensional stability, wear resistance, toughness, machinability, and applications.

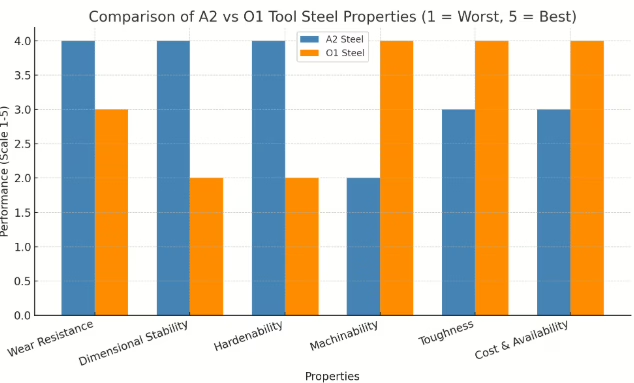

A2VS O1

The following chart provides a quantitative comparison of the performance of A2 and O1 tool steel, including wear resistance, dimensional stability, hardenability, machinability, toughness, and cost & availability.

Explore Our Other Products

D2/1.2379/SKD11

D3/1.2080/SKD1

D6/1.2436/SKD2

A2/1.23663/SKD12

O1/1.2510/SKS3

O2/1.2842

S1/1.2550

S7/1.2355

DC53

H13/1.2344/SKD61

H11/1.2343/SKD6

H21/1.2581/SKD7

L6/1.2714/SKT4

M2/1.3343/SKH51

M35/1.3243/SKH55

M42/1.3247/SKH59

P20/1.2311

P20+Ni/1.2738

420/1.2083/2Cr13

422 stainless steel

52100 bearing steel

440C stainless steel

4140/42CrMo4/SCM440

4340/34CrNiMo6/1.6582

4130

5140/42Cr4/SCR440

SCM415

High-Quality A2 Steel at Competitive Prices!

✅ Direct from Manufacturer – No middlemen, best factory pricing.

✅ Fast Global Shipping – Reliable delivery to your location.

✅ Free Technical Consultation – Get expert advice on selecting the right A2 steel for your needs.

✅ Bulk Order Discounts – Special pricing for large-volume purchases.

📩 Get a Free Quote Today! Fill out the form now and receive a response within 24 hours.