9Cr18MoV and 90Cr18MoV refer to the same type of steel. 9Cr18MoV is China GB/T 3280-1992’s old standard designation, while 90Cr18MoV is China GB/T 20878-2007’s new standard designation. 9Cr18MoV is an improved version of 9Cr18Mo. The addition of vanadium in 9Cr18MoV significantly improves its wear resistance and edge retention compared to 9Cr18Mo.

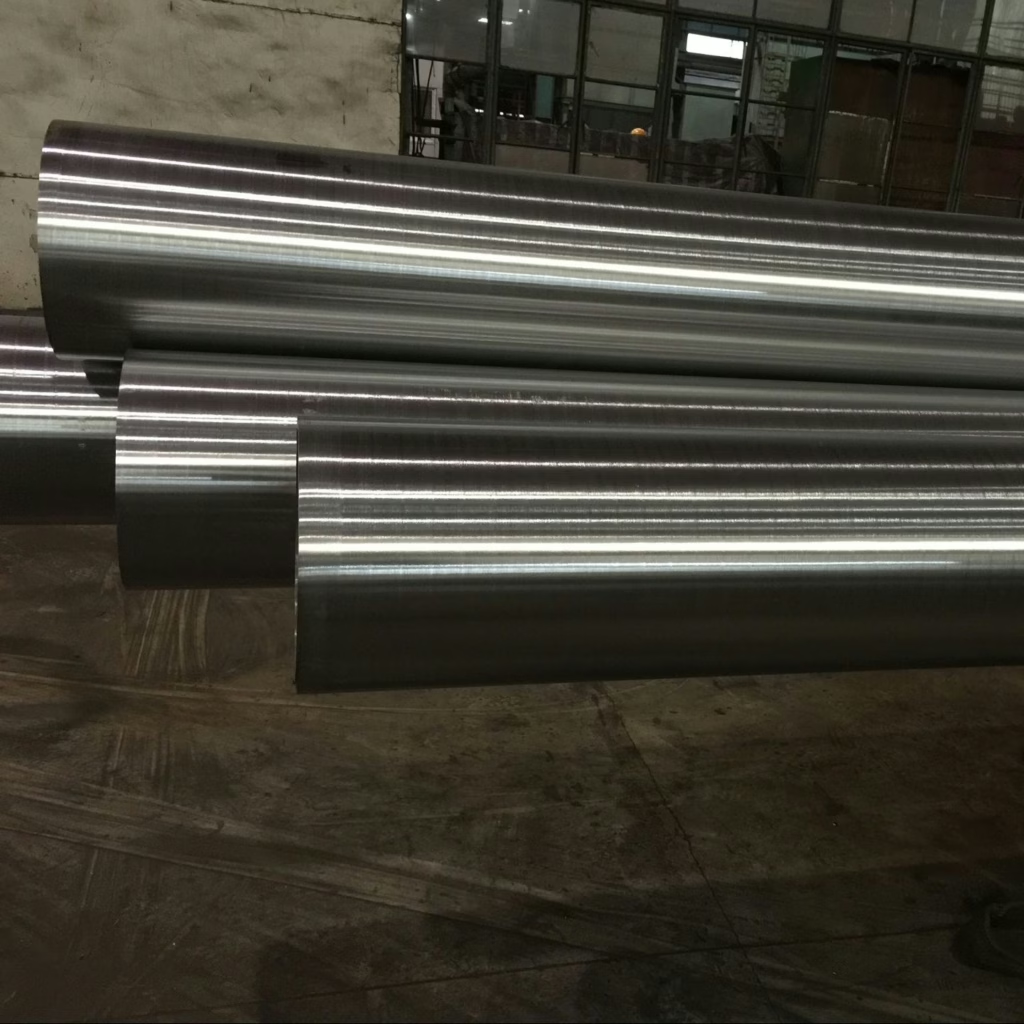

High-carbon, high-chromium martensitic stainless steel 9Cr18MoV(90Cr18MoV) is a modified 9Cr18 (95Cr18) steel with added molybdenum and vanadium. Both its hot strength and temper resistance are superior to 9Cr18 (95Cr18) steel. Its performance and applications are similar to 9Cr18 (95Cr18) steel. It is used to manufacture bearings that work in corrosive environments and strong oxidizing atmospheres, such as those in petroleum, chemical, and marine machinery. It is also suitable for making wear-resistant parts, mechanical tools, measuring tools, cutting tools, and surgical instruments. Furthermore, it is well-suited for high-load, high-wear, and corrosion-resistant plastic molds.

1. Chemical Composition(GB/T 20878—2007)

| C | Cr | Mo | V | Ni | Si (≤) | Mn (≤) | P (≤) | S (≤) |

| 0.85 ~ 0.95 | 17.00 ~ 19.00 | 1.00 ~ 1.30 | 0.072 ~ 0.12 | -0.6 | 0.8 | 0.8 | 0.04 | 0.03 |

Equivalent Grade and compositions

| Standard | Steel Grade | C | Cr | Mo | V | Ni | Si (≤) | Mn (≤) | P (≤) | S (≤) |

| Japan JIS | SUS440B | 0.75 ~ 0.95 | 16.00 ~ 18.00 | ≤(0.75) | — | -0.6 | 1 | 1 | 0.04 | 0.03 |

| USA ASTM | 440B S44003 | 0.75 ~ 0.95 | 16.0 ~ 18.0 | ≤0.75 | — | — | 1 | 1 | 0.04 | 0.03 |

| Europe EN | X90CrMoV18 1.4112 | 0.85 ~ 0.95 | 17.0 ~ 19.0 | 0.90 ~ 1.30 | 0.07 ~ 0.12 | — | 1 | 1 | 0.04 | 0.015 |

Please fill out the contact form to get the best quotation for 9Cr18MoV(90Cr18MoV) stainless steel

2. Hot Forging Process of 9Cr18MoV(90Cr18MoV)

Special attention should be paid to the hot working process of 90Cr18MoV (9Cr18MoV) steel. It is recommended to use a cold-charged furnace for heating, with a heating rate that should not be too fast, especially below 700°C. Additionally, the final forging temperature should be maintained at a higher level, and strict attention should be paid to the cooling conditions.

| Item | Heating Temperature/°C | Initial Forging Temp./°C | Final Forging Temp./°C | Cooling Method |

| Steel Ingot | 1130 ~ 1150 | 1080 ~ 1100 | 850 ~ 900 | Sand Cooling |

| Steel Billet | 1100 ~ 1120 | 1050 ~ 1080 | 850 ~ 900 | Sand Cooling |

3. Heat Treatment of 9Cr18MoV(90Cr18MoV)

The heat treatment procedure is as follows:

- Annealing:

- Temperature: 850 ~ 870°C

- Soaking Time: 4 ~ 6 hours

- Cooling: Furnace cool to below 600°C before discharging.

- Post-Annealing Hardness: ≤269 HBW

- Recrystallization Annealing:

- Heating Temperature: 730 ~ 750°C

- Cooling: Air cool.

4. Quenching and Tempering

- Quenching:

- Austenitizing Temperature: 1050 ~ 1070°C

- Quenching Medium: Oil

- As-Quenched Hardness: ≥58 HRC

- Tempering:

- Tempering Temperature: 160 ~ 180°C

- Soaking Time: 3 ~ 5 hours

- Final Hardness: ≥58 HRC

Get a Competitive Quote for 9Cr18MoV(90Cr18MoV) Stainless Steel

With over 20 years of forging expertise, Aobo Steel is your trusted partner for high-performance 9Cr18MoV(90Cr18MoV) stainless steel. We provide not just materials, but solutions. Leverage our deep industry knowledge and reliable supply chain for your project’s success.

✉ Contact us by filling out the form below.