Buy DC53 Steel Direct from Aobo Steel – Mill Prices

Get Competitive Pricing on Premium DC53 Tool Steel

Fast Delivery and Customization Options Available

DC53 Steel – High-Performance Tool Steel by Aobo Steel

DC53 steel is a high-chromium steel and a general-purpose high-toughness cold-work die steel. After quenching and tempering at 520-530°C, its hardness can reach 62-63 HRC, which is higher than that of SKD11 steel. Although its hardness is 2-3 HRC higher, its wear resistance is greatly improved, and its impact toughness is significantly enhanced, making it an excellent steel grade to replace D2.

Aobo Steel specializes in DC53 steel, which is available in round bar and plate forms. The composition and properties of the DC53 we supply fully comply with the standards.

Application Scenarios

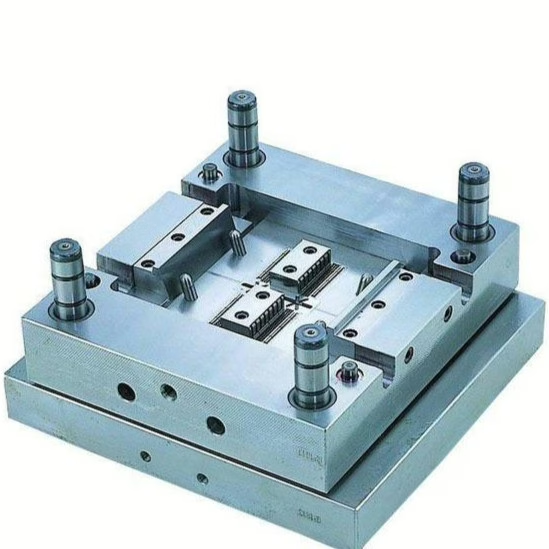

Blanking dies, cold forming dies, cold drawing dies, forming roll punches, and cold extrusion dies are essential for shaping and cutting materials in cold-working processes.

Precision blanking and various types of stamping dies for wire cutting processing are ideal for intricate and accurate cutting tasks.

Plastic deformation dies for difficult-to-machine materials: This includes cold forging, deep drawing, and thread rolling dies, as well as high-speed blanking punches and stainless steel sheet punches, suited for challenging material processing.

Cold stamping dies requiring high wear resistance, hardness, and toughness are perfect for demanding stamping operations that require durability and strength.

Dies with higher performance requirements than D2 steel and molds needing exceptional toughness: DC53 offers superior performance and excellent cost-effectiveness in these scenarios.

Large molds and precision molds: Suitable for applications where size and precision are critical.

Why choose Aobo Steel as your DC53 supplier

Under the premise of ensuring quality, our prices are approximately 3% lower than the market price.

Before shipment, all goods undergo 100% strict chemical, UT, and hardness testing.

With over 20 years of experience in forged tool steel production, we have a deep understanding of our products.

DC53 material properties

Dc53 steel composition

| Element | Carbon (C) | Silicon (Si) | Manganese (Mn) | Chromium (Cr) | Molybdenum (Mo) | Vanadium (V) |

| Percentage (%) | 0.90 – 1.10 | 1 | 0.4 | 8 | 2 | 0.3 |

Dc53 heat treatment

Hardening process

The first step is quenching. The process involves heating the material to a high temperature of 940-960°C, followed by rapid cooling, usually with air or oil cooling.

Tempering

After quenching, a tempering treatment is applied. There are two types of tempering for DC53 steel:

- Low-temperature tempering (180-220°C): This method is suitable for molds requiring very high hardness. The hardness after tempering can reach 60-62 HRC, which is particularly wear-resistant.

- High-temperature tempering (520-530°C): This method maintains a high hardness (62-63 HRC) and makes the steel more ductile, which is ideal for molds that need to be strong and durable.

Heat treatment precautions

- It should be in a step-warming manner to avoid heating too fast and causing the material to open up.

- After tempering the material, the air cools to room temperature.

- If the material is used to make precision molds, it is recommended that it be tempered at a high temperature of 520-530°C for the best results.

Premium DC53 Steel from Aobo Steel – Order Now!

High-Quality DC53 Die Steel for Exceptional Toughness

Consistent Quality and Reliable Supply from a Trusted Mill