D2 tool steel is classified under the “D” group, representing high-carbon, high-chromium...

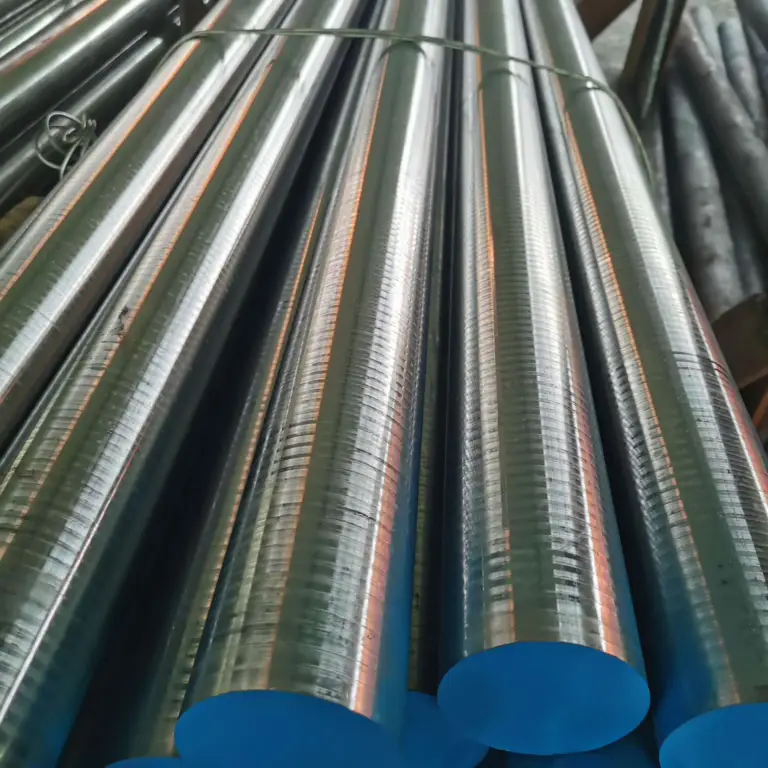

Introduction D2 tool steel is a prominent high-carbon, high-chromium cold-work tool steel, widely...

D2 tool steel is a high-carbon, high-chromium, air-hardening steel. Its hardness is affected by...

Hardness is a fundamentally critical property for tool steels, directly influencing their ability to...

O2 tool steel heat treatment is crucial to achieving optimal performance. O2 tool steel is an...

The objective of D6 tool steel heat treatment is to transform its annealed structure, consisting...

D3 tool steel heat treatment is critical to achieving its optimal properties, involving a series of...

As with all tool steels, L6 tool steel heat treatment is critical to achieving the best performance...

Today, we will discuss 420 stainless steel vs 316. Both types of steel are called stainless steel...