Is A2 Steel the Same as 304 Stainless Steel? A Clear Explanation

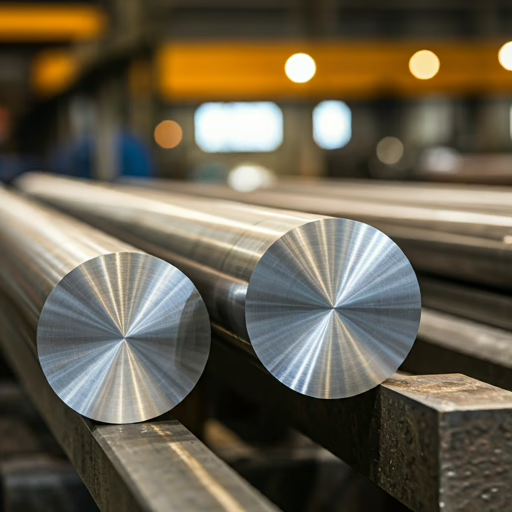

A common question we encounter is about steel designations, specifically regarding A2 and Type 304 stainless steel. It’s essential to be clear, as different global standards can sometimes lead to confusion. To put it directly: Yes, Type 304 stainless steel is often referred to as “A2” under the ISO 3506 standard. If you see “A2” […]

Is A2 Steel the Same as 304 Stainless Steel? A Clear Explanation Read More »