What is the difference between D2 and M2 tool steel? D2 tool steel is the preferred choice for cold working applications, offering excellent wear resistance and dimensional stability during heat treatment. M2 tool steel is the preferred choice for high-speed cutting operations, as it maintains its hardness (red hardness) at high temperatures.

AISI D2 Tool Steel: The Cold-Work Specialist

D2 is a high-carbon, high-chromium cold-work tool steel. It’s a grade we frequently recommend for long-run dies and applications where the tooling won’t see prolonged high temperatures. Its composition, typically around 1.50-1.55% carbon and 12-12.05% chromium, is what gives it its renowned properties.

Wear Resistance

D2 is truly outstanding here. It sets the standard for abrasion resistance in cold-work applications, thanks to a significant volume of hard, chromium-rich carbides (M7C3) in its microstructure. If wear is your primary concern in a cold environment, D2 is often the answer.

Toughness

While not a shock-resisting steel, D2 offers moderate toughness. It’s tougher than some other high-carbon, high-chromium grades, providing a good balance for many die applications.

Machinability and Workability

Be aware, D2 is known to be challenging to machine and grind. Its high alloy content makes it a bit stubborn, but the results are worth the effort.

Dimensional Stability in Heat Treatment

This is a major advantage for D2. As an air-hardening steel, it exhibits minimal movement or distortion during quenching. This precision is critical for complex dies and tools where tight tolerances are essential.

Heat Treatment

D2 is typically air-hardened from temperatures around 1010–1024 °C. We usually recommend multiple tempering cycles for optimal properties and hardness, often around 200 °C for maximum hardness.

Typical Applications

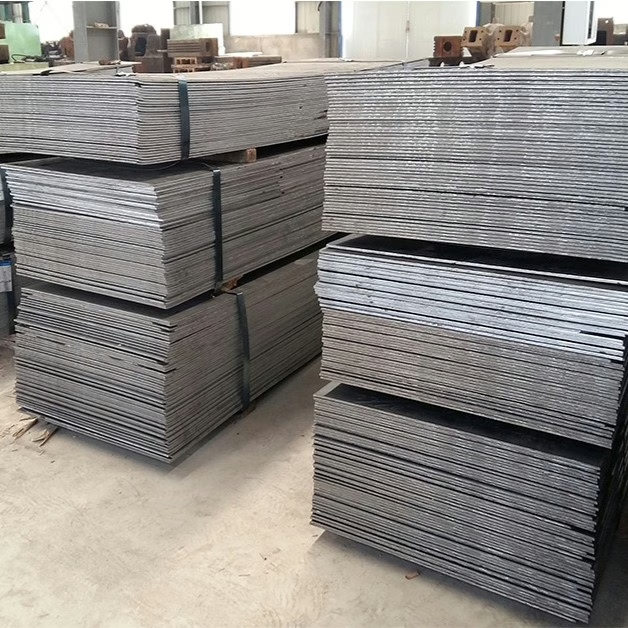

Think long-run blanking, forming, drawing, and lamination dies. It’s also excellent for shear and slitter blades, forging and trimming tools, brick molds, and punches. If you’re mass-producing parts, especially from steel, D2 is a popular and reliable choice. Key applications include:

- Long-run blanking dies

- Forming dies

- Drawing dies

- Lamination dies

- Shear blades

- Slitter blades

- Forging tools

- Trimming tools

- Brick molds

- Punches

Hardness

You’ll typically see D2 operating in the 56–64 HRC range, though it can go higher for specific needs.

AISI M2 Tool Steel: The High-Speed Performer

M2 is the most common molybdenum-based high-speed steel in industrial use, particularly for cutting tools. Its design is fundamentally different from D2; M2 is built to perform when the heat is on.

Hot Hardness and Red Hardness

This is M2’s defining characteristic. It retains its hardness and cutting edge even at the elevated temperatures generated during high-speed cutting operations. This “red hardness” is crucial for continuous, high-friction work.

Wear Resistance

M2 also boasts very high wear resistance and good abrasion resistance. While D2 might edge it out slightly in cold abrasion, M2’s wear resistance is exceptional, especially considering its ability to perform under heat.

Toughness

M2 generally offers good toughness, often slightly better than D2. This makes it more forgiving in applications where the tool might experience shock or intermittent cuts.

Machinability

Compared to D2, M2 is typically considered easier to machine. This can be a significant factor in manufacturing complex cutting tools.

Dimensional Stability in Heat Treatment

M2 can be quenched in air, oil, or salt bath. However, it generally exhibits more movement during hardening than D2, so precision heat treatment is even more critical.

Heat Treatment

M2’s heat treatment is more complex. It requires a specific heat-up ramp and a very short hold time at high austenitizing temperatures. Multiple tempering steps are almost always required to achieve its optimal properties.

Typical Applications

M2 is the go-to for drills, taps, and general-purpose saws that cut a wide range of materials from steel to plastics. Interestingly, it’s also used in some cold-work applications, especially for blanking thicker steel where carbide might lack sufficient shock resistance. Common applications include:

- Drills

- Taps

- General-purpose saws (for steel to plastics)

- Cold-work blanking dies (for thicker steel)

- Milling cutters

- Reamers

- Broaches

- Hobs

Hardness

M2 typically operates at a higher hardness than D2, usually in the 60–66 HRC range, making it ideal for demanding cutting tasks.

D2 vs. M2: Unpacking the Critical Differences

To summarize, here’s a direct comparison to help you differentiate:

| Feature | D2 Tool Steel | M2 Tool Steel |

|---|---|---|

| Primary Application | Cold-work tool steel for high wear resistance at room temperature. | High-speed steel designed for high-temperature cutting and maintaining hardness under friction. |

| Hot Hardness | Not suited for prolonged elevated temperatures. | Excels with very high hot hardness and red hardness. |

| Wear Resistance | Highly wear-resistant. Strength is in cold abrasion from chromium carbides. | Highly wear-resistant. Strength is from a combination of carbides and matrix hardness retention at temperature. |

| Toughness | M2 generally offers slightly better toughness. | Generally offers slightly better toughness than D2. |

| Machinability | Typically more difficult to machine. | Typically easier to machine than D2. |

| Dimensional Stability | Offers superior dimensional stability and minimal distortion during hardening compared to M2. | Less dimensionally stable during hardening compared to D2. |

| Operating Hardness | 56-64 HRC. | 60-66 HRC (typically operates at higher hardness levels). |

| Heat Treatment | Air-hardened and often tempered at lower temperatures. Simpler process. | More complex heat treatment cycle with short, high-temperature soaks and multiple tempers. |

| Composition | High in chromium (~12%) and carbon (~1.5%). | A molybdenum-based high-speed steel with significant Mo, W, Cr, and V. |

This comparison is for informational purposes. Always consult with a materials expert for specific application needs.

Making the Right Choice for Your Factory

Choosing between D2 and M2 isn’t about being “better” than the other; it’s about selecting the right tool for the job.

- If your tooling operates at elevated temperatures due to friction or high cutting speeds, M2’s hot hardness is the critical factor. Think drills, taps, and saw blades.

- If your application is a cold one requiring maximum abrasion resistance and minimal distortion during manufacturing—like a stamping die or a blanking tool—D2 is likely the preferred choice. You’ll gain wear resistance and dimensional stability, even if it means a bit more effort in machining.

Maximize Performance with Aobo Steel’s Premium M2 Tool Steel

Experience the superior wear resistance, exceptional toughness, and excellent red hardness of our M2 High-Speed Steel.

With over 20 years of specialized forging expertise, Aobo Steel delivers consistent quality and provides expert advice for your most demanding cutting tools, molds, and industrial components. Let us help you find the perfect M2 steel solution tailored to your specific application needs.

Ready to Enhance Your Operations?

Fill out the form below to get your competitive quote & expert consultation!