D2 vs D3 tool steel

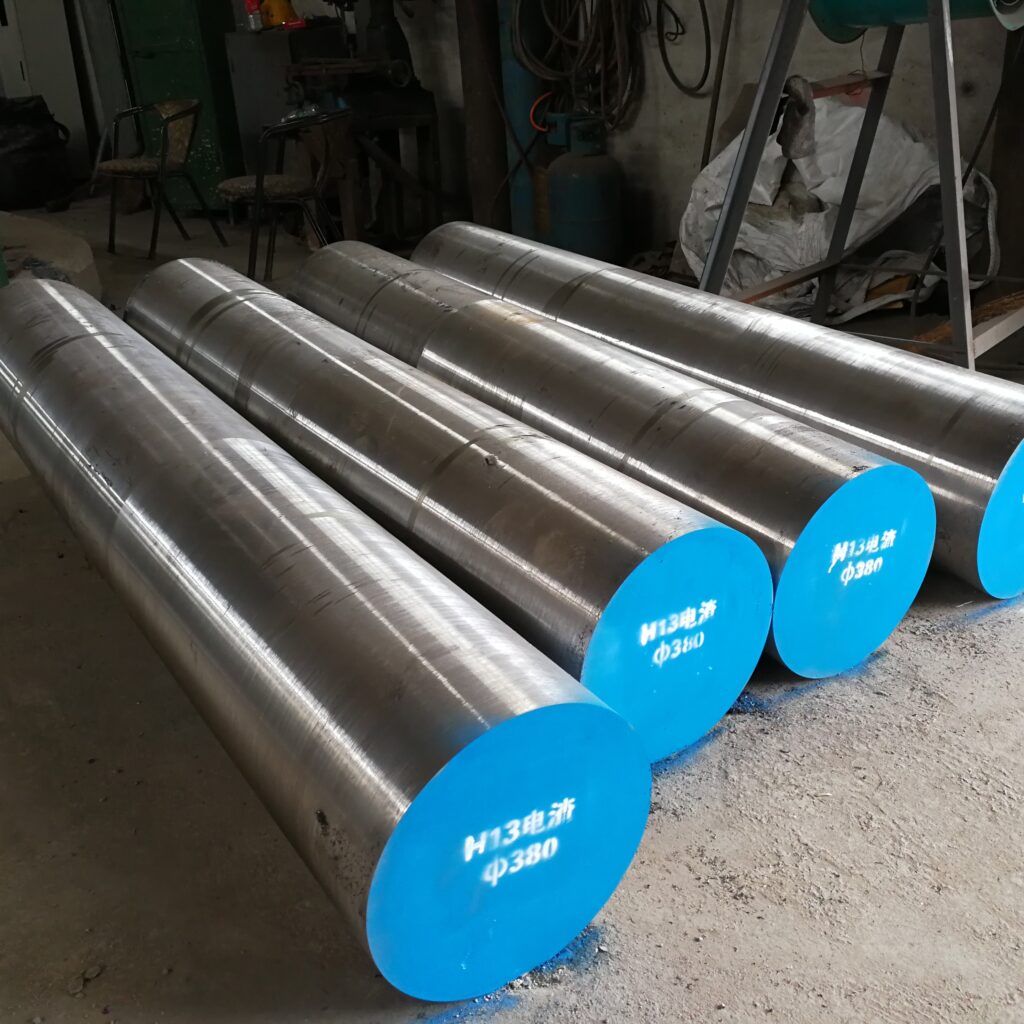

When choosing the right tool steel for your project, you may come across D2 tool steel and D3 tool steel. Both tool steels are high-carbon, high-chromium tool steels that are widely used in the tool and die industry for cold work tools such as cutting tools, dies, and punches. They are classified as D series […]