P20+Ni Tool Steel | 1.2738

AOBO STEEL – Trusted Global Tool Steel Supplier

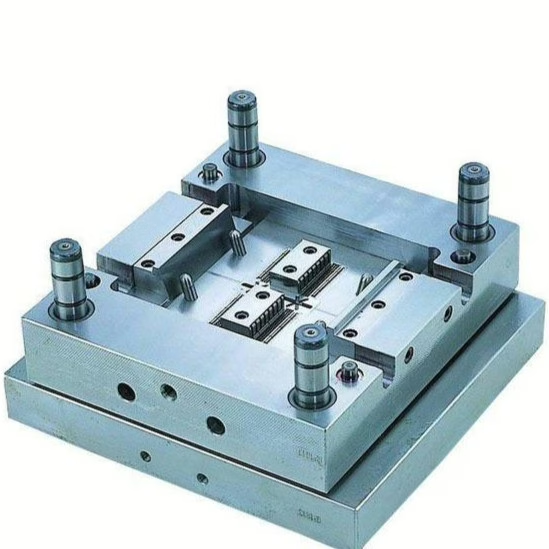

P20+Ni steel is a mirror-finish plastic mold steel developed by enhancing the American P20 steel with the addition of Ni alloy. This steel features high hardenability, excellent polishability, electrical discharge machining (EDM) performance, and texturing properties. Pre-hardened with high purity and uniform structure, it is ideal for high-demand plastic molds, particularly those requiring electrical discharge machining.

1. The applications of P20+Ni steel

- Ideal for manufacturing complex and high-precision plastic molds.

- Suitable for large-scale mirror-finish plastic mold production.

2. P20+Ni steel chemical composition

| Carbon (C) | Silicon (Si) | Manganese (Mn) | Phosphorus (P) | Sulfur (S) | Chromium (Cr) | Molybdenum (Mo) | Nickel (Ni) |

| 0.35 – 0.45 | 0.20 – 0.40 | 0.60 – 1.60 | ≤ 0.030 | ≤ 0.030 | 1.80 – 2.10 | 0.15 – 0.25 | 0.90 – 1.20 |

3. P20+Ni steel physical properties

| Property | Value | Unit |

| Density | 7.7 – 7.85 | g/cm³ |

| Hardness (Pre-hardened) | 280-320 | HB |

| ~28-32 | HRC | |

| Tensile Strength | 850 – 1300 | MPa |

| Yield Strength | 770 – 1000 | MPa |

| Elongation | 13 – 16 | % |

| Impact Toughness | 20 – 42 | J/cm² |

| Modulus of Elasticity | 205 – 212 x 10³ | MPa |

| Thermal Conductivity | ||

| * At 20°C | 29 – 35 | W/(m·K) |

| * At 350°C | ~34 | W/(m·K) |

| * At 700°C | ~33 | W/(m·K) |

| Thermal Expansion Coeff. | ||

| * 20-100°C | 11.2 – 12.0 x 10⁻⁶ | /K |

| * 20-200°C | 12.8 x 10⁻⁶ | /K |

| * 20-300°C | 13.5 x 10⁻⁶ | /K |

| Critical Temperatures | °C | |

| * Ac1 | 720 | °C |

| * Ac3 | 800 | °C |

| * Ms | 290 | °C |

| Soft Annealing Temp. | 710-740 | °C |

| Stress Relieving Temp. | 560-600 | °C |

| Hardening Temperature | 840-880 | °C |

| Tempering Temperature | 100-700 | °C |

4. P20+Ni equivalents DIN 1.2738

1.2738 steel is a German super-pre-hardened plastic mold steel, supplied in a pre-hardened condition that eliminates the need for additional heat treatment and allows direct machining into molds. It offers excellent machinability, facilitates cutting and polishing, and undergoes stress-relief annealing and surface nitriding treatment with minimal dimensional and hardness changes. Particularly suitable for plastic mold frames with a thickness greater than 400mm.

1.2738 steel chemical composition

| Carbon (C) | Silicon (Si) | Manganese (Mn) | Phosphorus (P) | Sulfur (S) | Chromium (Cr) | Molybdenum (Mo) | Nickel (Ni) |

| 0.35 – 0.45 | 0.20 – 0.40 | 1.30 – 1.60 | ≤ 0.030 | ≤ 0.030 | 1.80 – 2.10 | 0.15 – 0.25 | 0.90 – 1.20 |

Physical Properties of 1.2738 Steel

| Property | Value | Unit |

| Density | 7.85 | g/cm³ |

| Hardness (Pre-hardened) | 280-325 | HB |

| Tensile Strength | 850 – 1100 | MPa |

| Yield Strength | 770 – 980 | MPa |

| Elongation | 13 – 16 | % |

| Impact Toughness | 20 – 42 | J/cm² |

| Modulus of Elasticity | 205 x 10³ | N/mm² |

Interested in High-Quality P20+Ni Tool Steel?

Leverage Aobo Steel’s 20+ years of expertise in forged P20+Ni tool steel. Renowned for its excellent polishability, superior toughness, and good machinability, our P20+Ni is ideal for demanding plastic mold applications.

Take the Next Step:

Please fill out the form below to get a personalized quote, detailed specifications, or to consult with our tool steel experts today!