About Us

Aobo Steel started in 2003, originally as Fuding Equipment Engineering Co., Ltd. With over 20 years of direct experience, our core strength is processing and forging high-quality tool steels.

We expanded into international markets in 2017. Since then, we’ve established reliable partnerships with more than 30 customers in over five countries.

This deep experience in manufacturing tool steels allows us to supply a wide range of grades, including popular ones like D2, D3, H13, H11, O1, O2, A2, and others. Our tool steels are specifically made for industries where precision, strength, and durability are critical.

At Aobo Steel, we combine our technical know-how in tool steel with reliable service. Our goal is to provide practical solutions that meet each customer’s specific needs. We are focused on quality and reliability. You can count on us to deliver tool steel that performs consistently and supports your operations.

We are committed to enabling small and medium-sized factories worldwide to easily and quickly procure high-quality, cost-effective mold steel raw materials from China.

Our Main Products

Our main products are hot work tool steel and cold work tool steel. Our key competitive advantages include factory-direct pricing, consistent quality, and fast delivery. For more products, please visit our product page.

The Shapes We Offer

Surface Treatment Process

Quality Control

Quality control is fundamental to everything we do at Aobo Steel. Our testing team brings over 20 years of experience to the job. Their responsibility is to ensure every piece of tool steel meets strict standards before it ships.

Our quality process is thorough. It includes:

- Chemical composition analysis

- Metallographic examination

- Hardness testing

- Physical performance evaluation

- Importantly, ultrasonic testing (UT) to check for any internal defects.

Crucially, we conduct a 100% quality inspection on every single product before shipment. This confirms it meets all required specifications and relevant industry standards.

For added assurance, we fully support third-party inspections if a customer requests it. This offers another layer of verification for the material quality.

This thorough approach means you can rely on Aobo Steel to deliver tool steel that performs dependably in your specific applications.

Our Partner Clients

Serving Small and Medium-Sized Factories

We understand that sourcing tool steel can be a challenge for small and medium-sized factories, particularly with high minimum order quantities (MOQs) from many suppliers. Aobo Steel addresses this directly: our MOQ is 5 tons. This allows you to acquire the necessary tool steel grades without committing to excessive volume or tying up capital in surplus stock.

Working with Aobo Steel means:

- Manageable MOQ: Order quantities starting at just 5 tons.

- Consistent Quality: All tool steel meets strict specifications for reliable performance in your production.

- Ready Stock: Popular grades are often available from our inventory for faster delivery.

Partnering with Tool Steel Distributors

We understand that for tool steel distributors, competitiveness relies on pricing and reliable supply. Aobo Steel supports your business by offering competitive pricing structures and maintaining ready stock of key tool steel grades. This ensures you can respond quickly and effectively to your customers’ demands.

Partnering with us provides:

- Competitive Pricing: Our rates are structured to support your margins.

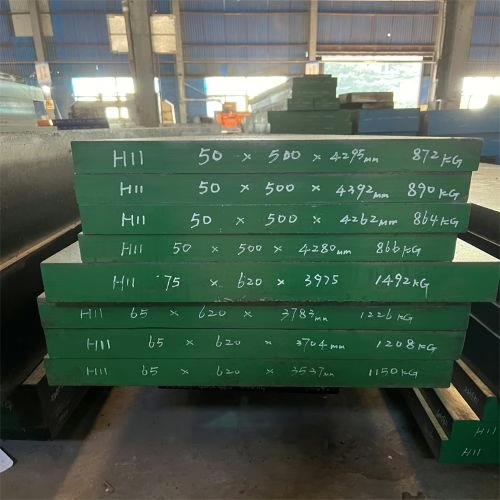

- Stock Availability: Key grades like D2, D3, H11, and H13 are consistently stocked for prompt shipment.

- Reliable Partnership: We focus on consistent supply and dependable support, building a long-term business relationship you can count on.

Where Our Customers Are Located

At Aobo Steel, we deliver top-quality tool steel worldwide, partnering with over 30 factories and distributors globally. Here’s a quick look at our key markets:

China

Our largest market, where we supply high-performance materials to leading manufacturers.

East & Northeast Asia

We work with clients in Vietnam, the Philippines, and India, providing precision tool steel for the automotive, electronics, and machinery industries.

Eastern Europe

Serving countries like the Czech Republic and Slovenia, we support construction, heavy machinery, and tooling sectors with durable materials.

South America

In Brazil, Chile, and Colombia, we cater to the agriculture, mining, and automotive industries with specialized tool steels.

Aobo Steel is committed to reliable quality and timely delivery, helping industries worldwide achieve their goals.

Our Price Positioning

With nearly 20 years of market experience, we have a sharp understanding of price trends at all times. Among numerous competitors, we consistently uphold the principle of offering the best prices to serve a growing number of global customers.

How We Produce Tool Steel

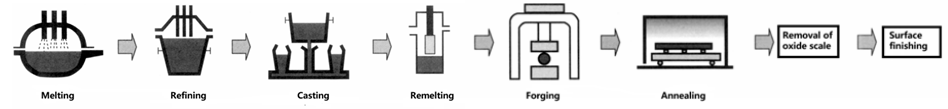

The diagram below illustrates the production process of forged tool steel. Our production mainly focuses on providing high-quality forged round bars and plates. The process begins with melting and refining the raw materials, casting, and optional remelting for improved purity. The forged steel is then shaped, annealed for better machinability, and processed to remove the oxide scale. Finally, surface finishing is applied to ensure the desired quality and appearance.

This image shows an Electroslag Remelting (ESR) machine in operation. ESR is a specialized process used to improve the purity and quality of steel. During this process, a pre-cast ingot is remelted under a layer of molten slag, which acts as a purifier by removing impurities and inclusions. The refined steel solidifies as it cools, resulting in a material with a uniform structure, enhanced mechanical properties, and superior surface quality. This process is essential for producing high-performance tool steels and other critical materials.

In this video, you can see the forging process of a heated tool steel ingot. After being heated to the required temperature, the tool steel ingot is placed under a mechanical press. The forging press applies immense pressure to shape the steel into the desired form, enhancing its internal structure and mechanical properties. This process eliminates internal defects, refines the grain structure, and improves the material’s strength and durability, making it ideal for high-performance applications.

This video showcases a centerless grinding machine processing a tool steel round bar. In this operation, the round bar is precisely ground to achieve the required diameter and surface finish without needing a center to hold the material. This high-efficiency process ensures excellent dimensional accuracy, smooth surface quality, and consistent roundness, making the finished product suitable for demanding industrial applications.