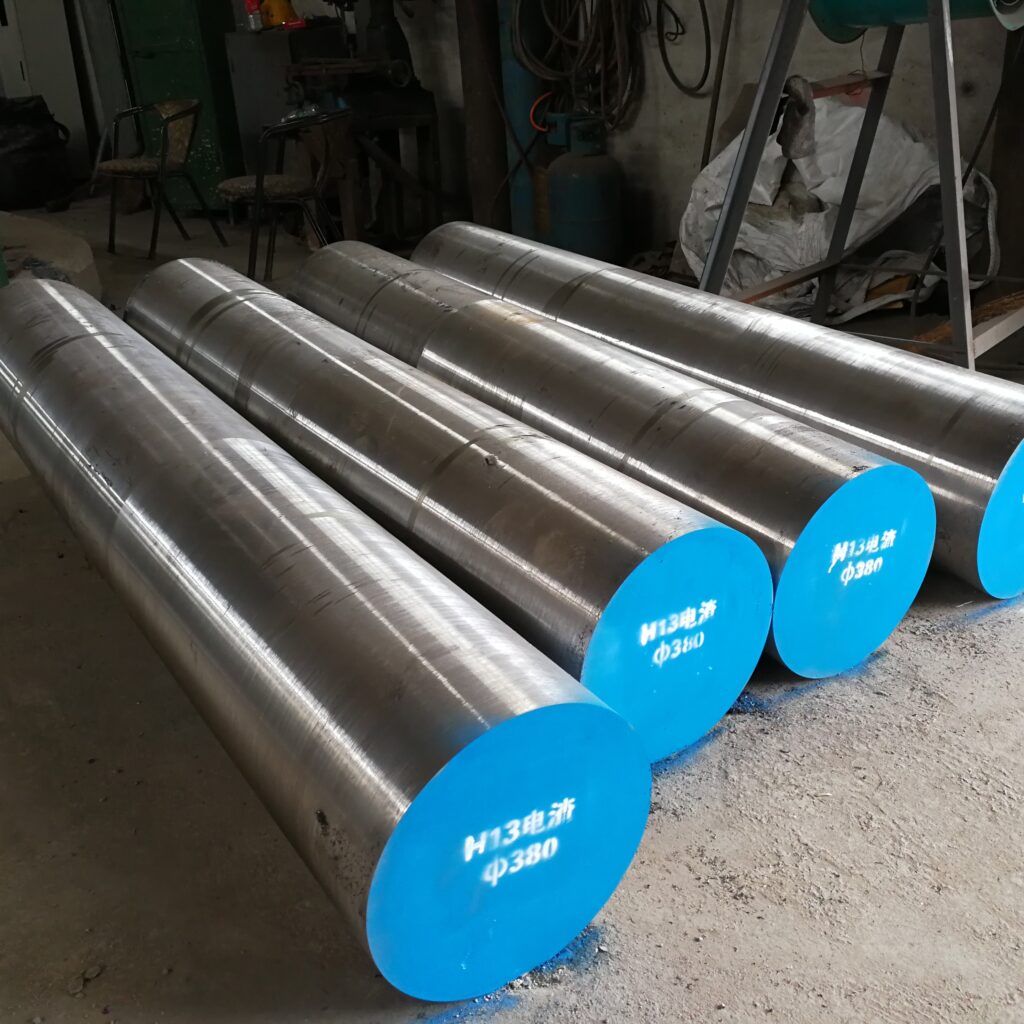

ร้านค้าของลูกค้า

THE FOLLOWING STORIES OF OUR CLIENTS ARE ALL REAL. TO PROTECT THE PRIVACY OF OUR CLIENTS, WE HAVE REFRAINED FROM MENTIONING THEIR NAMES. Stories from an Indian client In 2017, we had the privilege of forming a partnership with one of India’s largest importers of tool steel, thanks to an introduction from one of our […]