D2 Steel: Applications in Tool Making

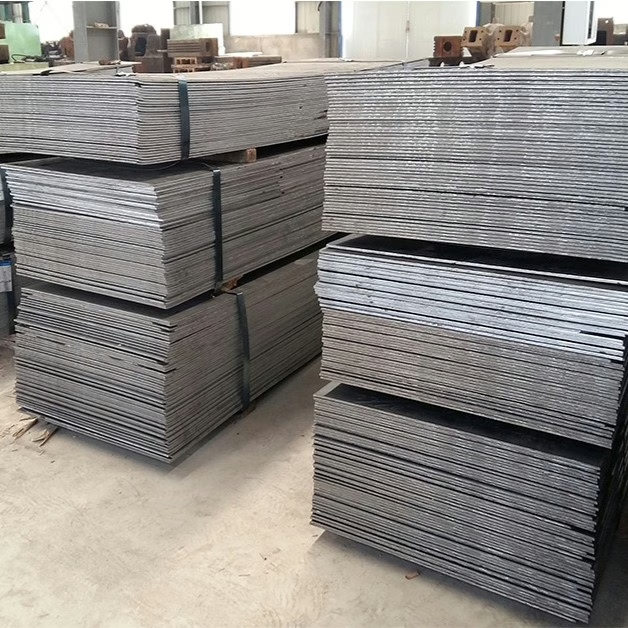

As a professional tool steel supplier, we will provide you with a detailed introduction to the specific characteristics of D2 tool steel and its applications in tool manufacturing. It is the most common type of high-carbon, high-chromium cold-work tool steel. Among all the tool steels we supply, D2 has the largest volume of supply, including […]